Method for carrying out advanced treatment on papermaking sewage

A technology for advanced treatment of paper-making sewage, applied in biological water/sewage treatment, adsorption water/sewage treatment, oxidized water/sewage treatment, etc. solve problems well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

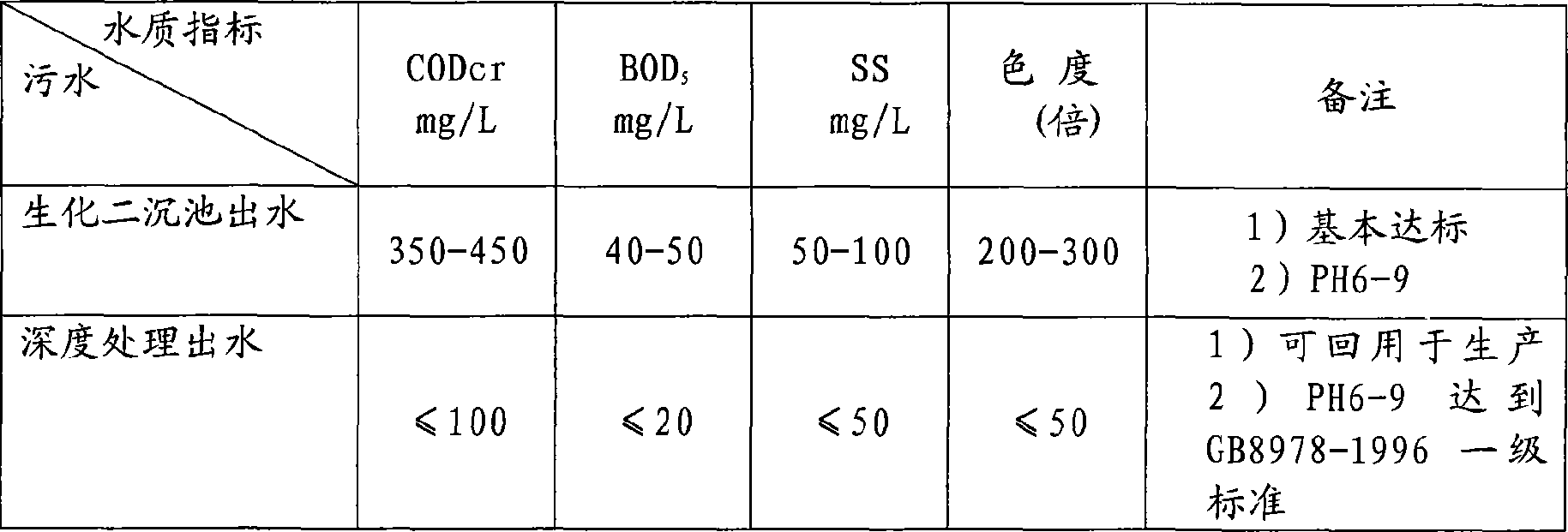

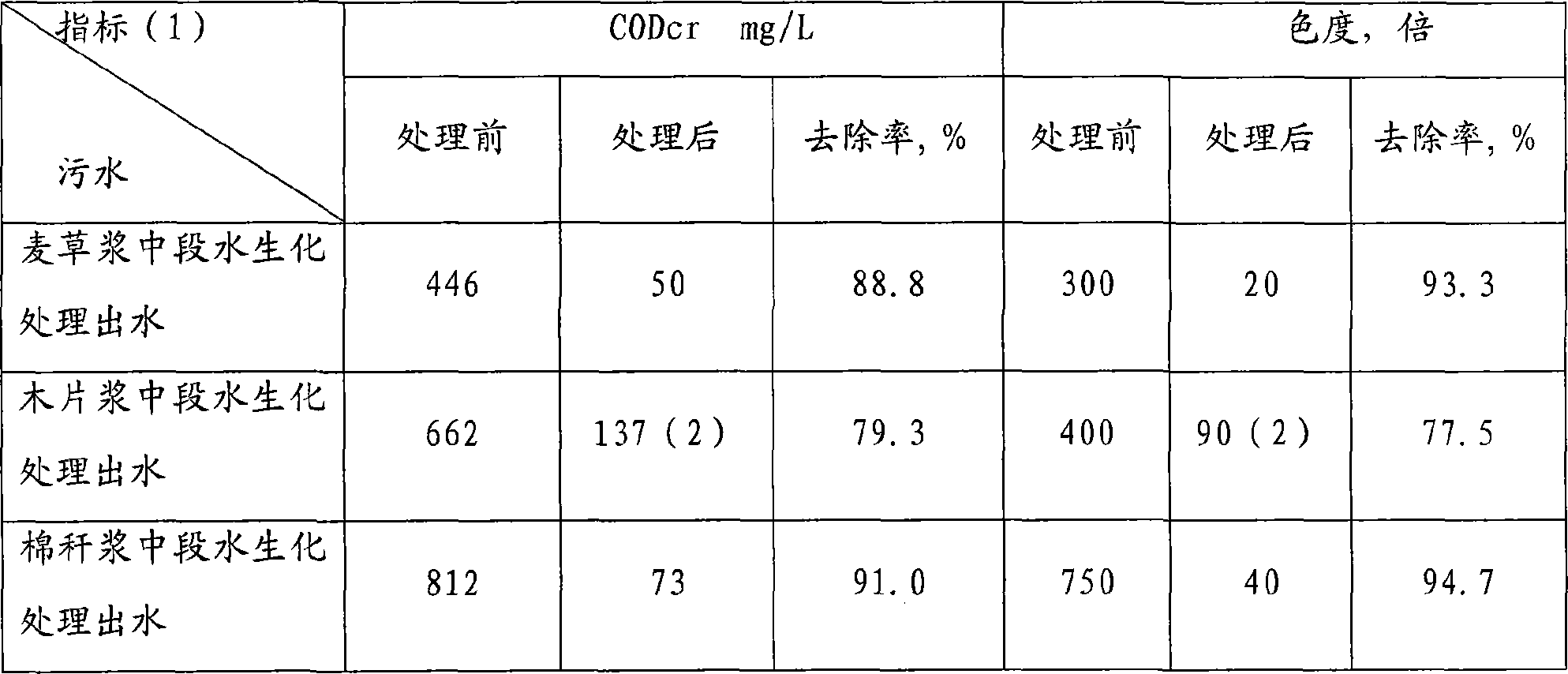

[0024] When carrying out the expansion test, firstly, several tons of biochemical treatment effluent from the middle section of papermaking water are taken from the paper mill, and poured into several large-volume plastic tanks, each tank can store 1-2m of sewage 3 , used as a raw water storage tank. Before the test starts, the aluminum salt or iron salt or iron-aluminum salt mixture solution is formulated to a concentration of 10%-30%, and the cationic or anionic or nonionic PAM is formulated to a concentration of 0.05%-0.5%. After the start of the test, according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com