Rotating scraper evaporator

A technology of rotating scraper and evaporator, applied in the field of mechanical processing, can solve the problems of unstable product quality, low evaporation intensity and high operating cost, and achieve the effects of high operating flexibility, high evaporation intensity and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

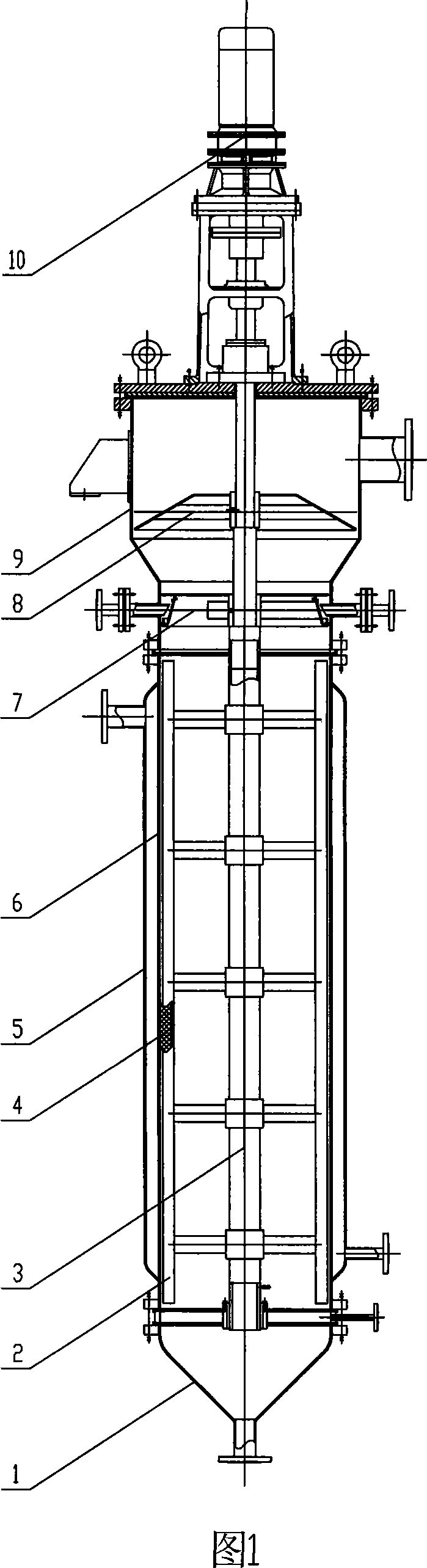

[0011] The present invention is mainly composed of bottom head 1, scraper frame 2, main shaft 3, movable scraper 4, jacket 5, evaporation section 6, distributor 7, separator 8, separation cylinder 9, motor and transmission system 10, etc.

[0012] When the present invention installs, install with 4 ear type bearings on the outer wall of the separating cylinder 9 and the frame.

[0013] The motor and transmission system 10 of the present invention adopts a 5.5KW 4-pole explosion-proof motor, which is equipped with a needle wheel reducer with a speed ratio of i11 and a mechanical seal of 205, and is connected and fixed on the LDJ65 frame. Through this mechanism, the main shaft 3 can obtain 130 rpm, that is, the linear velocity of the outer edge of the scraper is 4.08m / s. The separator 8 is placed in the vaporization chamber 9 (that is, the separation cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com