Method for preparing molecular sieves dryer special used for pneumatic braking system

A technology of pneumatic brakes and molecular sieves, applied in clay preparation devices, chemical instruments and methods, clay processing equipment, etc., can solve problems such as damage to metal components, poor dry and wet strength, and poor vibration and wear resistance, and achieve enhanced strength, No fragmentation, the effect of reducing waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

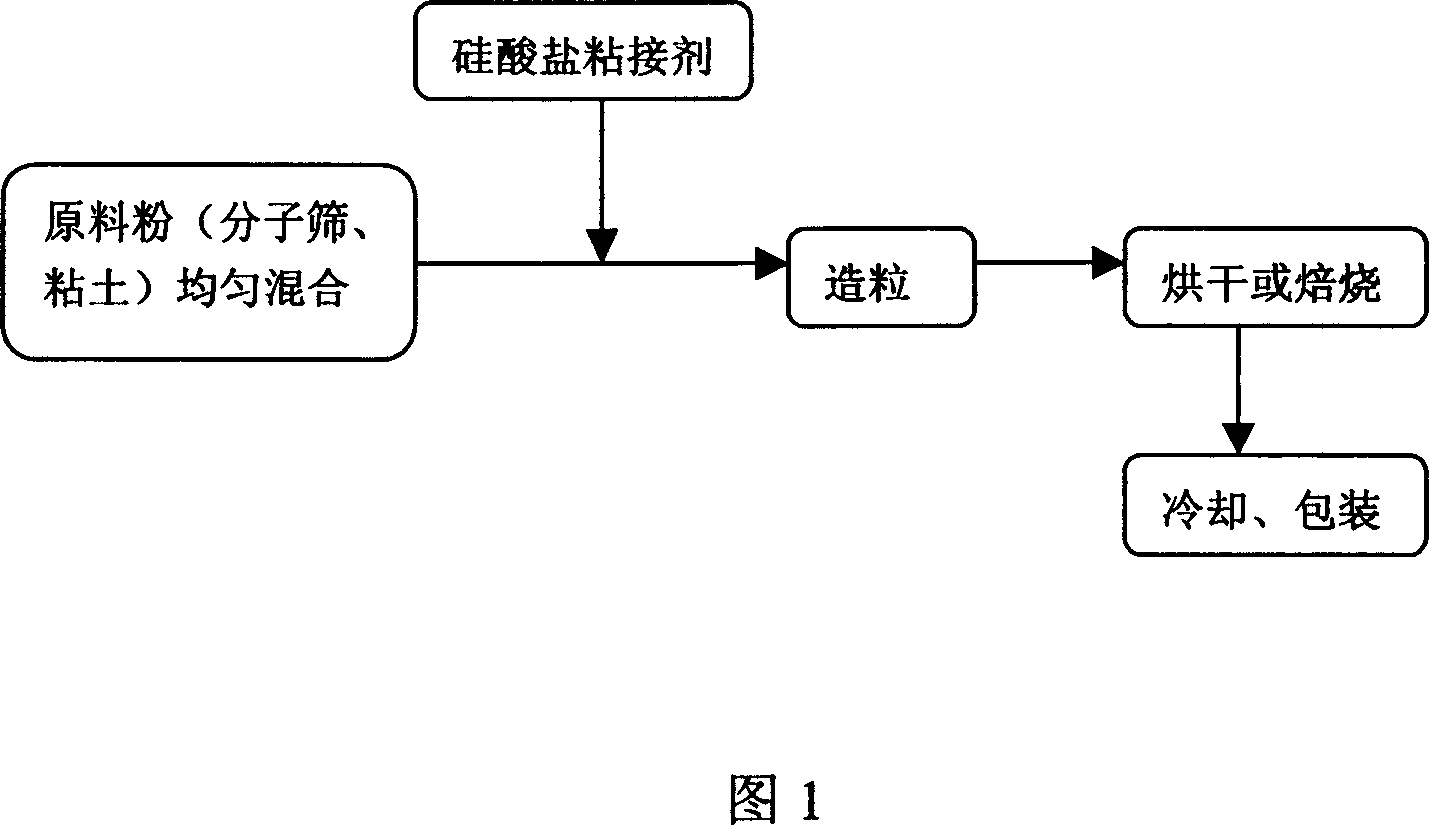

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of a special molecular sieve desiccant for a pneumatic brake system, uniformly mixing powdery 3A molecular sieve raw powder and clay to obtain a powder mixture (molecular sieve raw powder accounts for 80wt%, clay accounts for 20wt%), and adds a liquid silicate binder Bonded to make 0.5 ~ 5.0mm particles (the ratio of powder mixture and silicate binder is 80wt%: 20wt%), the particles are put into the muffle furnace and baked at 700 ° C, after complete cooling, vacuum Packaging, that is, get special molecular sieve desiccant for pneumatic brake system.

[0031] The obtained product has the following properties: high dynamic adsorption capacity, dynamic water adsorption capacity of 22.0wt% under 25°C and 50% RH conditions, bulk specific gravity: 0.85g / cm 3 , The compressive strength is 55N in dry state, and the compressive strength is 38N after being completely immersed in water for 5 seconds.

Embodiment 2

[0033] A preparation method of a special molecular sieve desiccant for a pneumatic brake system, except that the added 4A powdered molecular sieve raw powder, spherical particles with a diameter of 1.6-2.4mm are put into a muffle furnace and roasted at 200°C, other operations are carried out in the same way Example 1, the properties of the obtained product are as follows: dynamic water adsorption capacity of 25.2wt% under 25°C and 50% RH conditions, bulk specific gravity: 0.82g / cm 3 , The compressive strength in dry state is 67N, and the compressive strength is ≥42N after being completely immersed in water for 5 seconds.

Embodiment 3

[0035]A preparation method of a special molecular sieve desiccant for a pneumatic brake system, uniformly mixing 3A powdered molecular sieve and clay to obtain a powdery mixture (the original powder of molecular sieve accounts for 60wt%, and clay accounts for 40wt%), adding a liquid silicate binder for bonding Make 3~5mm particle (the ratio of powdery mixture and silicate binder is 60wt%: 40wt%), this particle is put into muffle furnace and is dried under 300 ℃ condition; Other operation is the same as embodiment 1. The properties of the obtained product are as follows: dynamic water adsorption capacity of 19.8wt% at 25°C and 50% RH, bulk specific gravity: 0.83g / cm 3 , The compressive strength in dry state is 86N, and the compressive strength is ≥44N after being completely immersed in water for 5 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com