Lithium ion secondary battery

A secondary battery and lithium ion technology, applied in secondary batteries, secondary battery components, battery electrodes, etc., can solve problems such as deterioration and promotion of battery characteristics, increase the proportion of active materials, prevent the reduction of negative electrode capacity, and improve The effect of battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

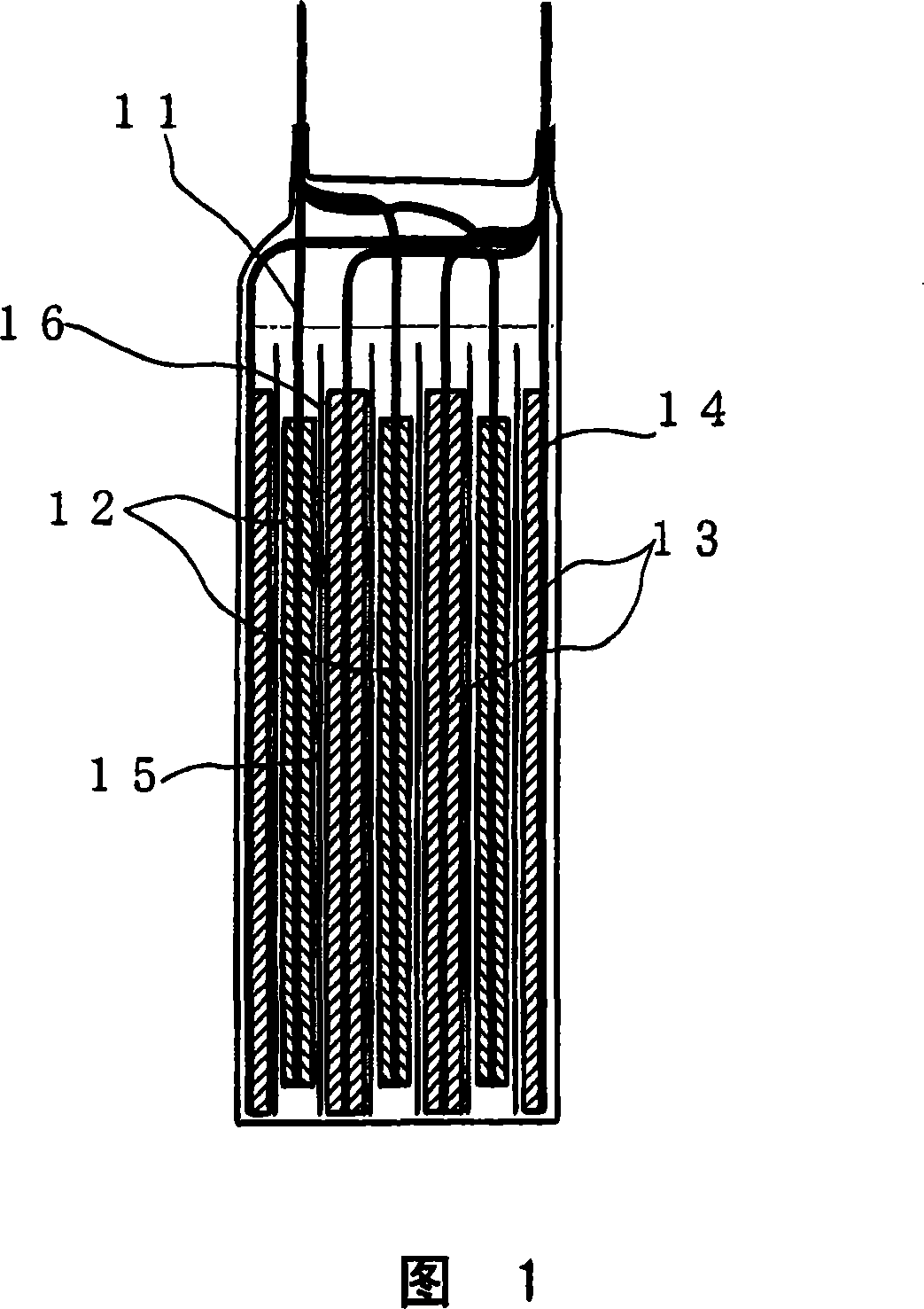

Image

Examples

Embodiment

[0035] battery production

[0036] Positive electrode production

[0037] A positive electrode active material and a conductivity-imparting agent were mixed and uniformly dispersed in N-methyl-2-pyrrolidone (NMP) in which a binder was dissolved to prepare a slurry. As the positive electrode active material, LiMn is used 2 o 4 , as the conductivity imparting agent, carbon black was used, and as the binder, polyvinylidene fluoride (PVdF) was used. This slurry was coated on an aluminum foil for a current collector with a thickness of 25 μm, and then NMP was evaporated to form a positive electrode layer. The solid content ratio in the positive electrode layer was: positive electrode active material:conductivity imparting agent:binder=80:10:10 (% by mass).

[0038] Production of negative electrode

[0039] For Examples 1 to 11 and Comparative Examples 1 to 10, a carbonaceous material with a volume average particle diameter of 3 μm or less and a moisture absorption value shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| interplanar spacing | aaaaa | aaaaa |

| interplanar spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com