Semiconductor laser device and method for fabricating the same

A technology of a laser device and a manufacturing method, which can be applied to semiconductor laser devices, semiconductor lasers, laser devices, etc., can solve problems such as difficulty in ensuring high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Next, a semiconductor laser device according to an embodiment of the present invention, specifically, a monolithic two-wavelength semiconductor laser device and a manufacturing method thereof will be described with reference to the drawings.

[0090] (Structure of a two-wavelength semiconductor laser device)

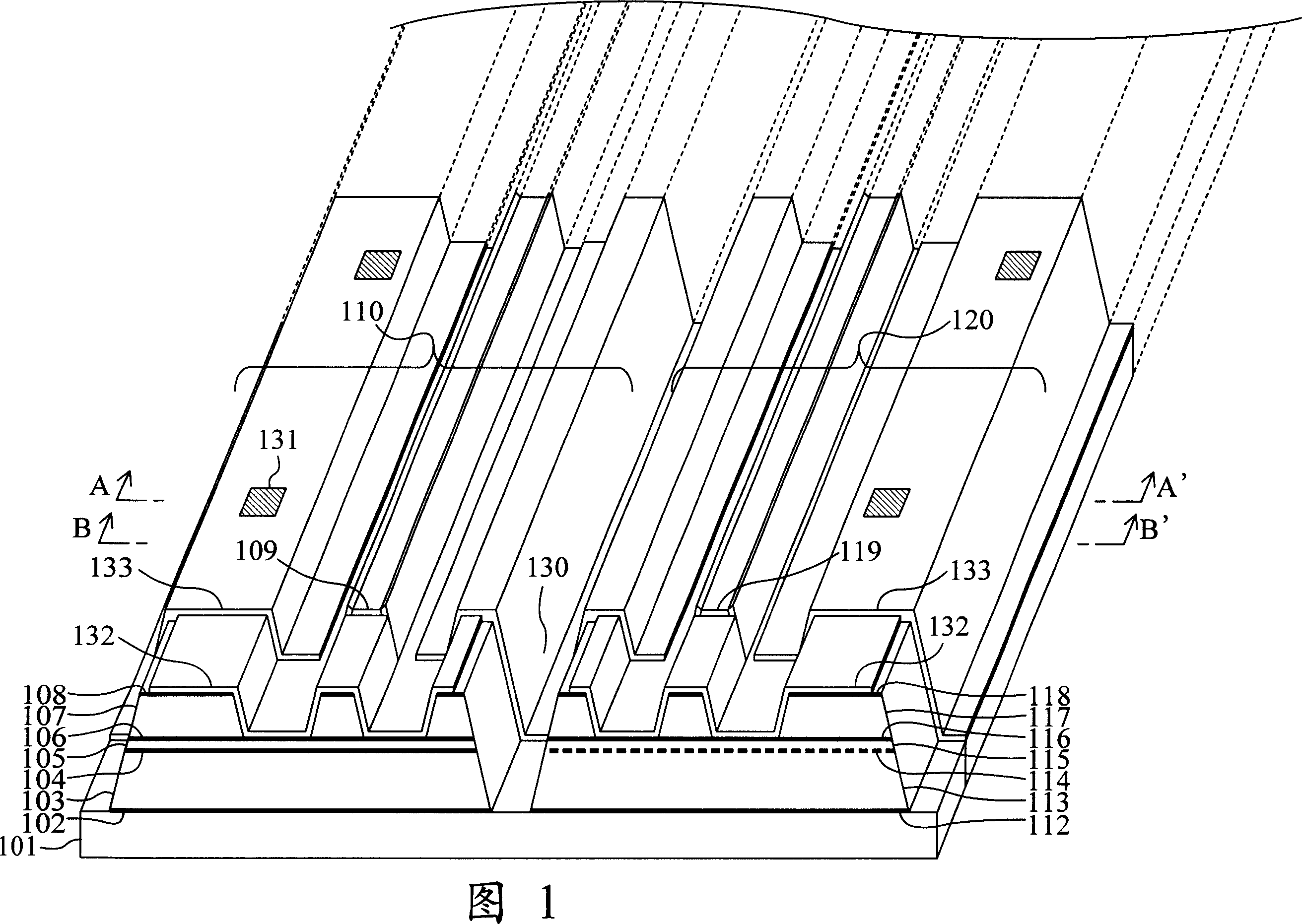

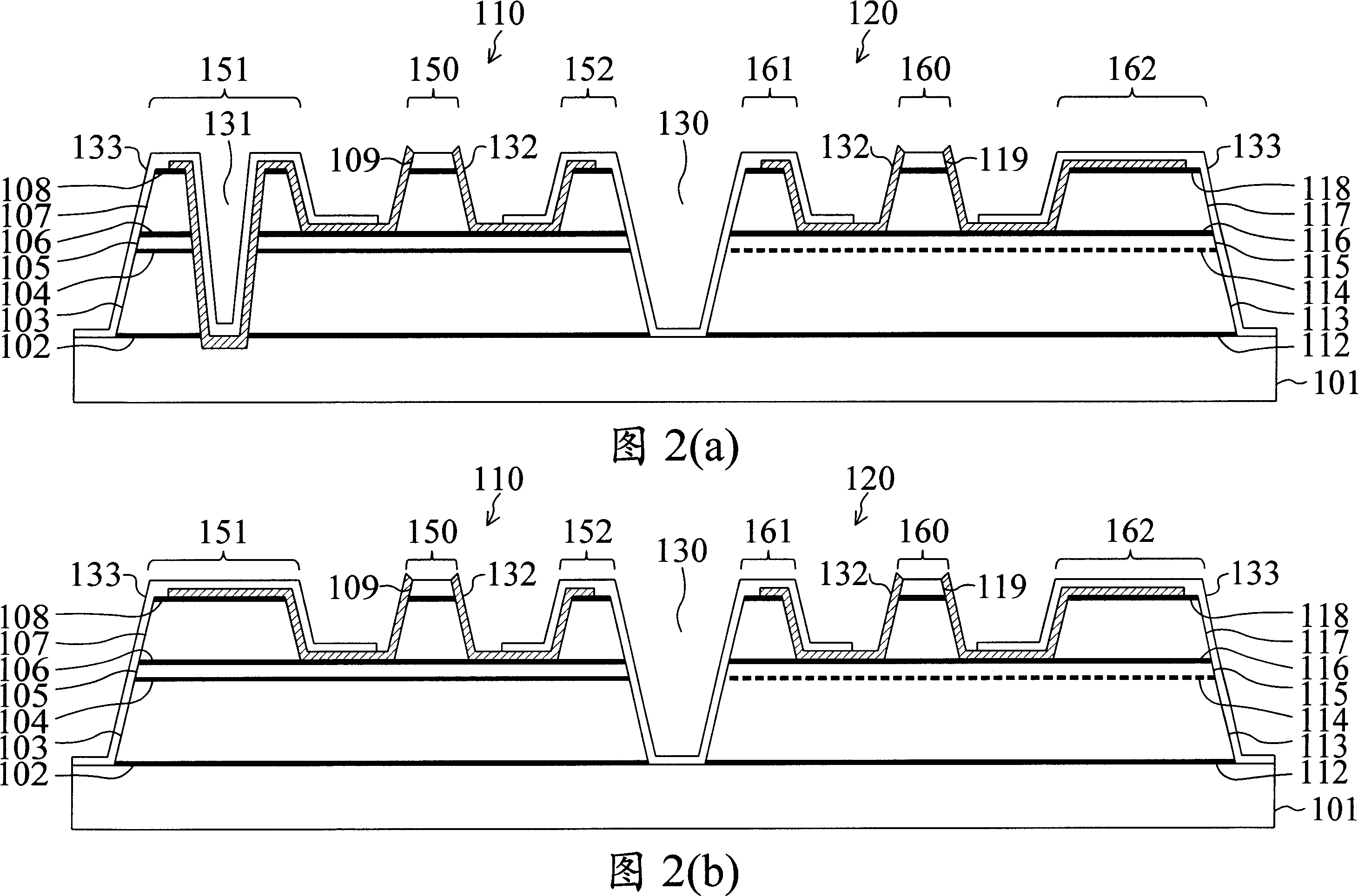

[0091] Fig. 1 is a perspective view showing the structure of the semiconductor laser device involved in this embodiment, and Fig. 2(a) is a cross-sectional view of line A-A' in Fig. sectional view), Fig. 2(b) is a sectional view of line B-B' in Fig. 1 (the sectional view without crossing the above-mentioned cavity).

[0092] As shown in Fig. 1 and Fig. 2(a), Fig. 2(b), the monolithic dual-wavelength semiconductor laser device of this embodiment has an infrared light on a substrate 101 made of n-type gallium arsenide (GaAs), for example. The structure of the laser element 110 and the red laser element 120 is as follows.

[0093] First, the infrared laser element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com