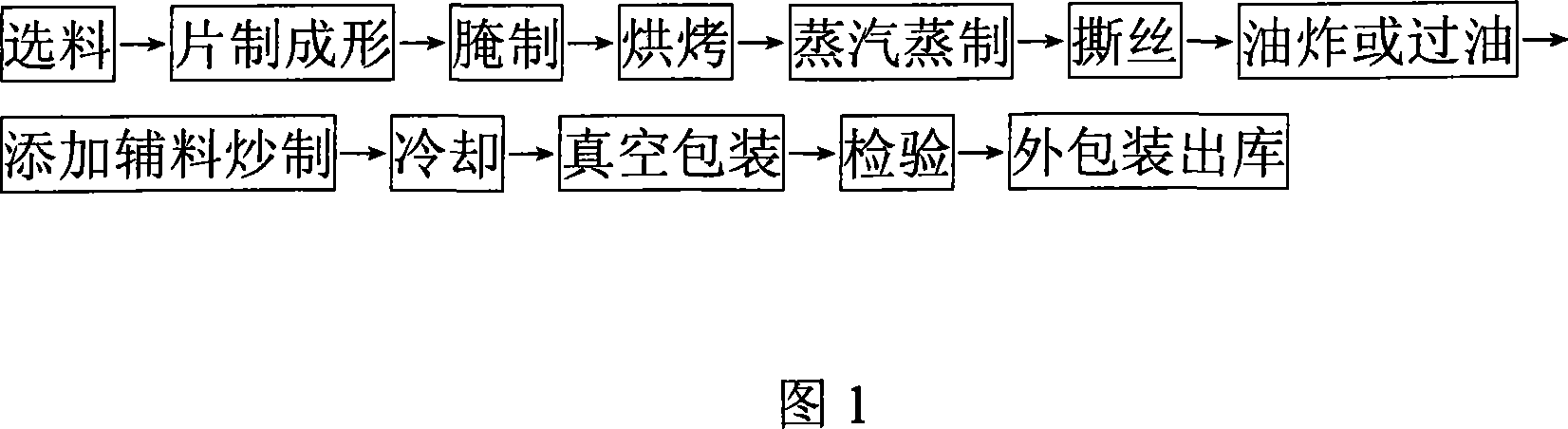

Process of producing dragon wisker beef

A production method and beef technology, applied in food preparation, application, food science and other directions, can solve the problems of accelerated bacterial reproduction, waste, and high water activity, achieve natural and beautiful shape and color, reduce production costs, and taste comfortable products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention is described in further detail below in conjunction with accompanying drawing and embodiment: the preparation method of this asparagus beef is as follows:

[0009] 1) Material selection: choose the front and rear legs of cattle.

[0010] 2) Slice and shape: cut the beef into thin slices with a thickness of 0.3 to 1.5 cm after removing the tendons and oil.

[0011] 3) Pickling: Mix 2 kg of table salt, 2.5 kg of white wine, and 0.02 kg of sodium nitrite evenly, then add them to 100 kg of beef slices and mix evenly, and then send them to a low-temperature room whose temperature is controlled at 0°C to 7°C. Take it out after marinating for 10-18 hours.

[0012] 4) Baking: Hang the marinated raw meat into the baking room, and then push it into the charcoal oven for baking. The baking temperature is maintained at 50°C-140°C, and baked for 12-24 hours until the raw material The moisture of the meat is reduced to about 40%. After cooling to room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com