Punch head lubricating solid grain for pressure casting and its prepn

A technology of solid particles and punches, which is applied in lubricating compositions, casting molding equipment, casting molds, etc., can solve the problems of machine and worker working environment pollution, affecting the life of casting molds, and excessive dripping dosage, etc., and achieve easy mechanical automation Effects of emission, porosity reduction, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

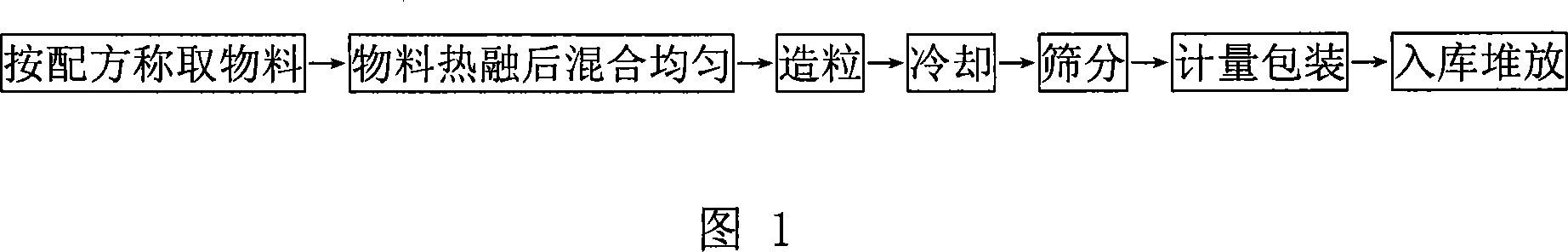

[0035] The preparation of embodiment 1 white solid lubricating beads

[0036] Formula: 30 kg of paraffin wax, 25 kg of low molecular weight polyethylene with a molecular weight of 3000, 20 kg of hydraulic oil with a viscosity of 46 grades, 10 kg of epoxy resin, and 15 kg of talcum powder.

[0037] Preparation method: (1) Put paraffin wax, low molecular polyethylene, hydraulic oil, and epoxy resin into a melting material bucket, heat to 90°C, and after all melt into liquid, stir and mix evenly; (2) After stirring for half an hour, Then slowly add talcum powder into the material barrel within 1 hour, and continue to stir for half an hour to mix evenly; (3) Spray the mixture to granulate, cool, and sieve, and take the product with a particle size of 1mm to 1.6mm and quantitatively pack it into 5 kg / package, put in storage.

Embodiment 2

[0038] The preparation of embodiment 2 white solid lubricating beads

[0039] Formula: 70 kg of paraffin wax, 10 kg of low molecular weight polyethylene with a molecular weight of 5000, 5 kg of hydraulic oil with a viscosity of 46 grades, 3 kg of epoxy resin, and 12 kg of talcum powder.

[0040] Preparation method: (1) Put paraffin wax, low molecular polyethylene, hydraulic oil, and epoxy resin into a melting barrel, heat to 130°C, and after all melt into liquid, stir and mix evenly; (2) After stirring for half an hour, Then slowly add talcum powder into the material barrel within 40 minutes, and continue to stir for half an hour to mix evenly; (3) Spray the mixture to granulate, cool, and sieve, and take the product with a particle size of 1mm to 1.6mm and pack it quantitatively into 5 kg / package, put in storage.

Embodiment 3

[0041] The preparation of embodiment 3 white solid lubricating beads

[0042] Formula: 50 kg of paraffin wax, 15 kg of low molecular weight polyethylene with a molecular weight of 3000, 10 kg of hydraulic oil with a viscosity of 46 grades, 5 kg of epoxy resin, and 20 kg of talcum powder.

[0043] Preparation method: (1) Put paraffin wax, low molecular polyethylene, hydraulic oil, and epoxy resin into a melting barrel, heat to 130°C, and after all melt into liquid, stir and mix evenly; (2) After stirring for half an hour, Then slowly add talcum powder into the material tank within 1 hour, and continue to stir for half an hour to mix evenly; (3) Carry out granulation, cooling, and sieving of the mixture, and quantitatively pack the product with a particle size of 2mm to 3mm into 5 kg / package, put in storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com