Method for preparing low voltage light-emitting macro ZnO semiconductor single crystal material

A single crystal material, semiconductor technology, applied in luminescent materials, semiconductor devices, chemical instruments and methods, etc., to achieve the effect of changing resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

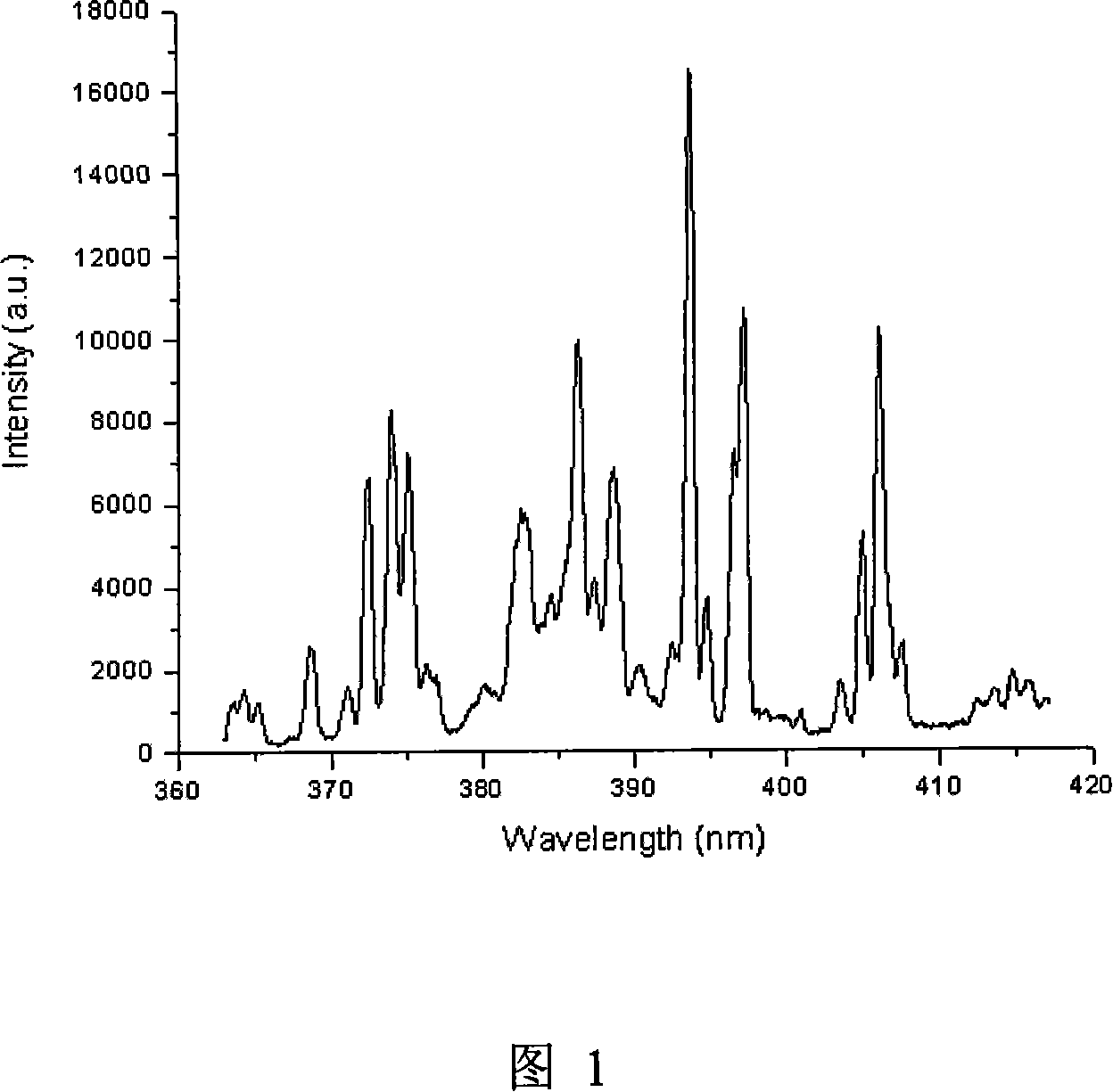

Image

Examples

Embodiment 1

[0017] (1) Use a quartz plate as a substrate, ultrasonically clean it in absolute ethanol and dry it in air;

[0018] (2) Put the single ZnO semiconductor single crystal structure stripped from the macroscopic ultra-long ZnO single crystal cluster on the silicon wafer, and only the two ends are bonded with silver paste; put it in an oven, bake at 120 ° C for 15 minutes, Then bake at 375°C for 20 minutes; make a single ZnO semiconductor single crystal structure firmly bonded to the silicon wafer, and prepare a sample for testing;

[0019] (3) Put the sample into the vacuum chamber, turn on the vacuum pump to evacuate to 5Torr;

[0020] (4) Pass H at a certain flow rate 2 Gas, adjust the ventilation valve of the vacuum chamber to keep the vacuum degree in the growth chamber constant at 10Torr; turn on the switch of the plasma processor and adjust the power to 170W; under this power, keep the hydrogen plasma gas bombarding the sample for 60 minutes;

[0021] (5) After the bomba...

Embodiment 2

[0024] (1) Use a glass slide as a substrate, ultrasonically clean it in absolute ethanol and dry it in air;

[0025] (2) Put the single ZnO semiconductor single crystal structure stripped from the macroscopic ultra-long ZnO single crystal cluster on a glass slide, and only the two ends are bonded with silver paste; put it in an oven and bake at 125°C for 15 minutes , and then baked at 385 ° C for 20 minutes; make a single ZnO semiconductor single crystal structure firmly bonded on a glass slide to prepare a sample for testing;

[0026] (3) Put the sample into the vacuum chamber, turn on the vacuum pump to evacuate to 1 Torr;

[0027] (4) Pass H at a certain flow rate 2 Gas, adjust the ventilation valve of the vacuum chamber to keep the vacuum degree in the growth chamber constant at 20Torr; turn on the switch of the plasma processor and adjust the power to 250W; under this power, keep the hydrogen plasma gas bombarding the sample for 40 minutes;

[0028] (5) After the bombar...

Embodiment 3

[0031] (1) Use a quartz plate as a substrate, ultrasonically clean it in absolute ethanol and dry it in air;

[0032] (2) Put the single ZnO semiconductor single crystal structure stripped from the macroscopic ultra-long ZnO single crystal cluster on the silicon wafer, and only the two ends are bonded with silver paste; put it in an oven, bake at 120 ° C for 15 minutes, Then bake at 375°C for 20 minutes; make a single ZnO semiconductor single crystal structure firmly bonded to the silicon wafer, and prepare a sample for testing;

[0033] (3) Put the sample into the vacuum chamber, turn on the vacuum pump to evacuate to 2.5Torr;

[0034] (4) Pass H at a certain flow rate 2 Gas, adjust the ventilation valve of the vacuum chamber to keep the vacuum in the growth chamber constant at 16Torr; turn on the switch of the plasma processor and adjust the power to 380W; under this power, keep the hydrogen plasma gas bombarding the sample for 30 minutes;

[0035] (5) After the bombardmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com