Method for modifying and producing waste asphalt bamboo fibre and its apparatus

A technology of asphalt carbon fiber and carbon fiber, which is applied in the direction of carbon fiber, fiber treatment, textiles and papermaking, etc., to achieve the effect of wide application range, high strength and firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

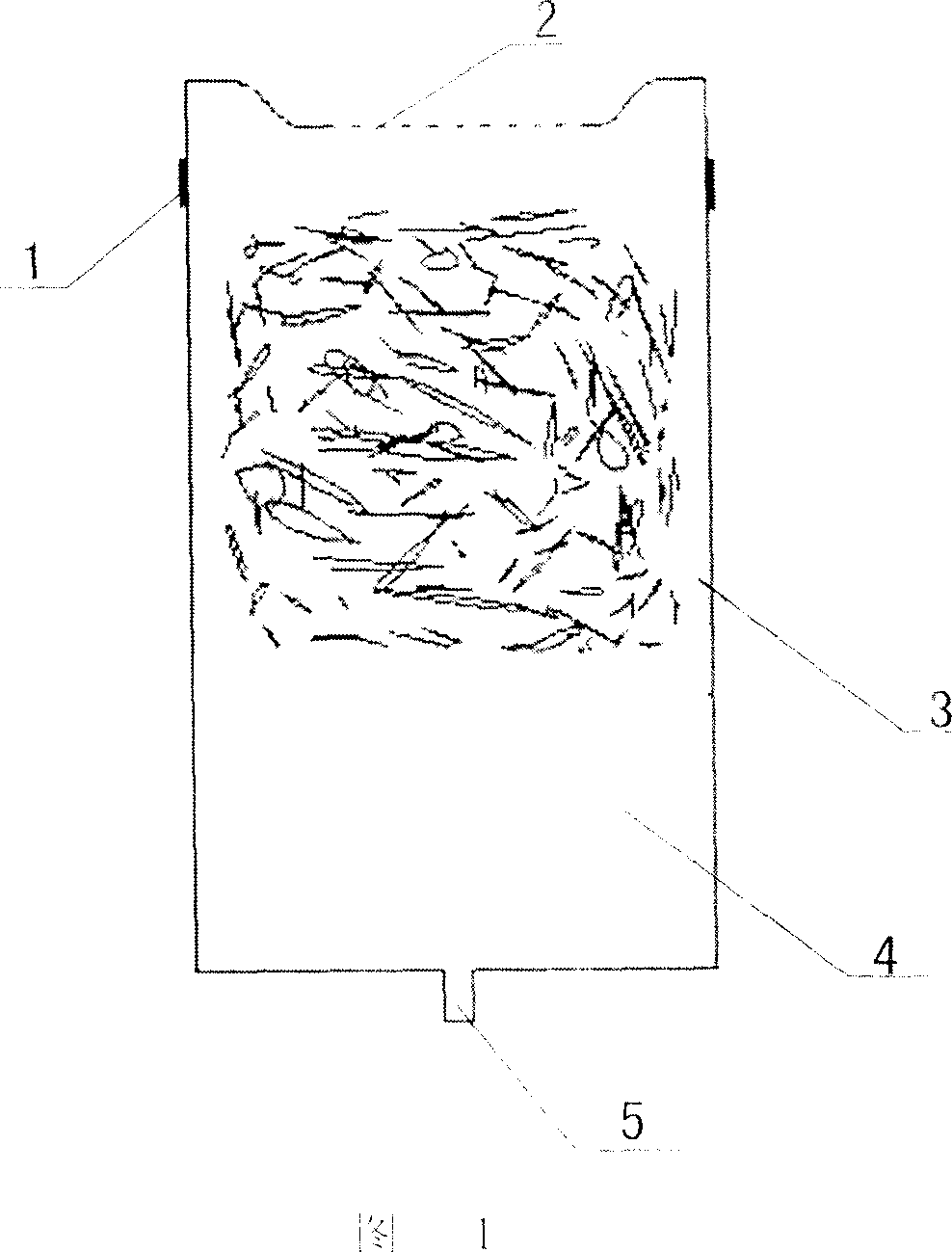

Image

Examples

Embodiment 1

[0043] Embodiment 1: Carding the carbon fiber felt or bundles, so that there is a certain space between the carbon fiber monofilaments, which are relatively monofilament-like independent, and then placed in an upright diameter of 200mm. The inner wall is coated with a silicone-coated circular tube-shaped container middle. The water-based polyurethane emulsion (PU) with a solid content of 10% is atomized with a gas compression atomizer, and the droplet diameter is 0.1-3um to become an aerosol, and the aerosol is described from a circular tube with an air flow rate of 20L / min. Introduced at the bottom of the container to coat the carbon fibers. After 15 minutes, take out the coated carbon fiber, dry it at room temperature for 3 days, and then use it.

[0044] Use a fluorescence microscope to observe the microscopic condition of the carbon fiber surface coating, and take pictures, as shown in Figure 2, the composite coating is in the shape of joints.

[0045] The treated and dr...

Embodiment 2

[0046] Embodiment 2: The carbon fiber mat or bundle is kept in a certain space between each carbon fiber, and then placed in a vertical tube container with a diameter of 200 mm and an inner wall coated with silicone coating. The styrene-acrylic emulsion with a solid content of 10% is atomized with a gas compression atomizer, and the droplet diameter is 0.1-3um. The aerosol is introduced from the bottom of the circular tube with an air flow rate of 20L / min, and the carbon fiber is coated. cover. After 15 minutes, take out the coated carbon fiber, dry it at room temperature for 3 days, and then use it.

[0047] Use a fluorescence microscope to observe the microscopic condition of the carbon fiber surface coating, and take pictures, as shown in Figure 3, the composite coating is in the shape of joints, and the bulge is not uniform.

[0048] The treated and dried carbon fibers were prepared according to the preparation method of the single-fiber cement sample, and the fiber embed...

Embodiment 3

[0049] Embodiment 3: The carbon fiber mat or bundle is kept in a certain space between each carbon fiber, and then placed in a vertical silicone-coated pipe with a diameter of 200 mm. The EVA emulsion with a solid content of 10% is atomized with a gas compression atomizer, the droplet diameter is 0.1-3um, and the aerosol is introduced from the bottom of the circular tube with an air flow rate of 20L / min to coat the carbon fiber. After 15 minutes, take out the coated carbon fiber, dry it at room temperature for 3 days, and then use it.

[0050] Use a fluorescence microscope to observe the microscopic condition of the carbon fiber surface coating, and take pictures, as shown in Figure 4, the composite coating is in the shape of joints, and the bulge is dense but not obvious.

[0051] The treated and dried carbon fibers were prepared according to the preparation method of the single-fiber cement sample, and the fiber embedding length was 2.5mm, and cured for 7 days at 20°C and RH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com