Flame-retardant resin composition and molded article using same

A resin composition, flame retardant technology, applied to molded articles with excellent flame retardancy, and other molded articles, can solve problems such as lower oil resistance, impossibility of use, wear resistance or strength, and pressure contact characteristics, etc., To achieve the effect of solving environmental problems, not easy to damage, and having flame retardancy or wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0135] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited thereto.

[0136] Magnesium hydroxide (1)~(5)

[0137] Magnesium hydroxide (1)-(5) was produced by the following method.

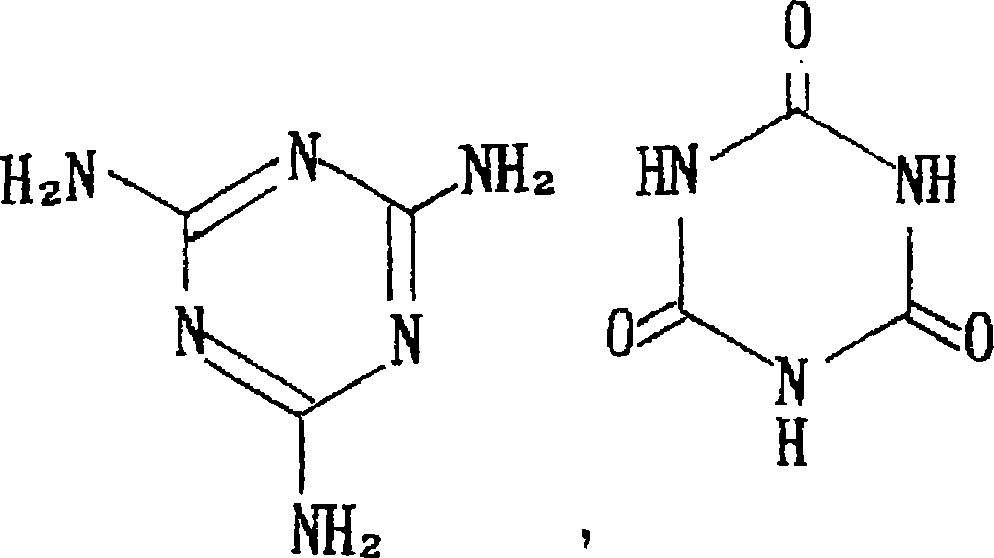

[0138] Add 400 ml of magnesium chloride aqueous solution (Wako Pure Chemical Industries, Ltd.) adjusted to a concentration of 0.5 mol / L in the autoclave and boric acid (manufactured by BORAX) in an appropriate amount within the range of 0.01 to 150 mol % relative to magnesium chloride, and stir 121 ml of 3N caustic soda solution was added dropwise and reacted at room temperature (25° C.) for 30 minutes to obtain a magnesium hydroxide particle suspension.

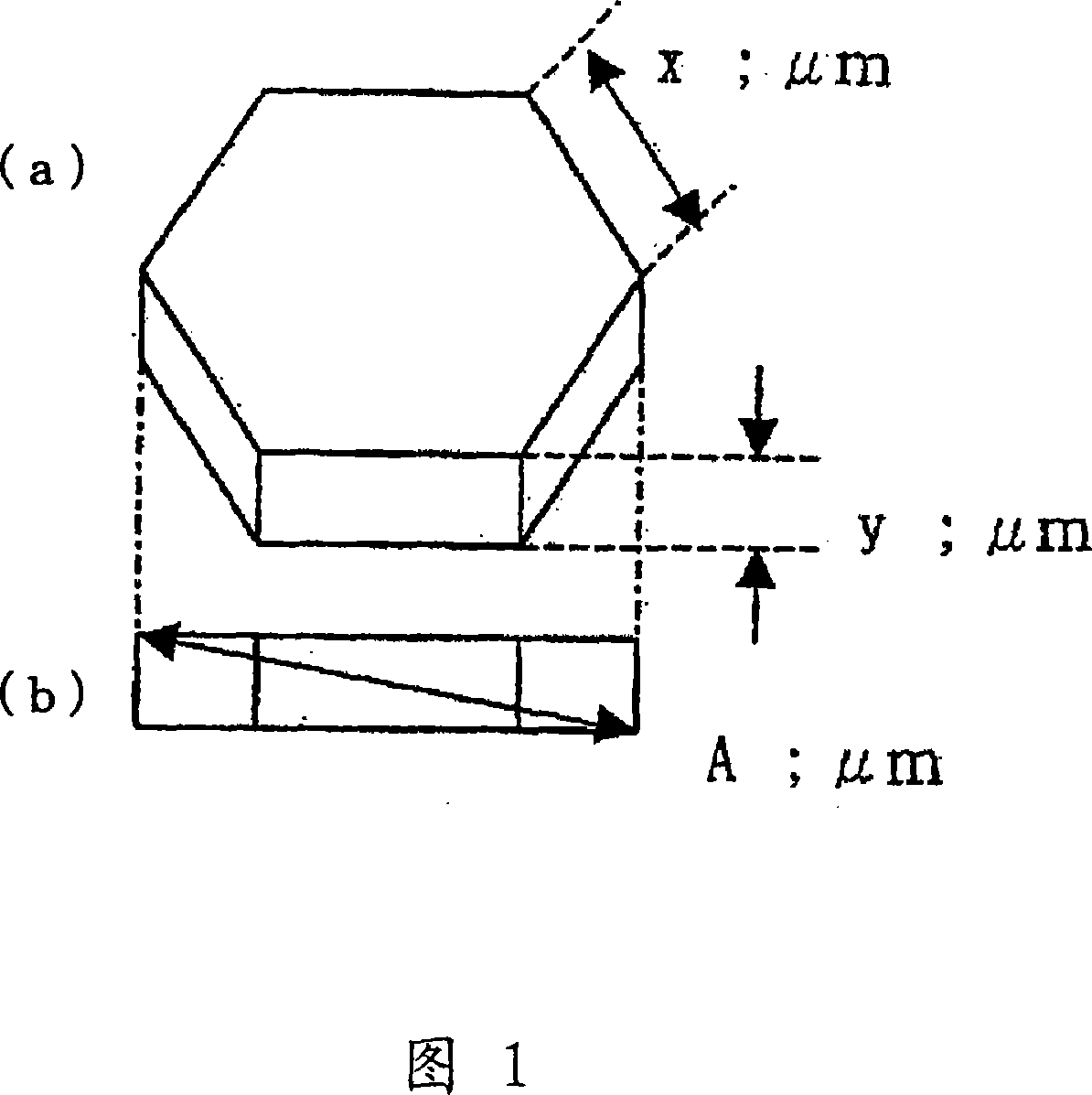

[0139] The suspension was hydrothermally treated at 180°C for 2 hours, dehydrated, washed with water (200 ml), and dried at 105°C for 24 hours to obtain magnesium hydroxide having a predetermined aspect ratio and BET specific surface area. The obtained magnesium hydroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com