Organic nano particle and dispersive combination, photo-sensitive resin combination, trans-printing material, filter, liquid display device and CCD device

A technology of liquid crystal display device and photosensitive resin, which is applied in the direction of photosensitive materials, nano optics, organic dyes, etc. used in optomechanical equipment, and can solve the problems of not being able to obtain color filters, unsatisfactory color purity and contrast, etc., and achieve good Dispersibility, excellent display properties, effects of stable dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0126] The preparation conditions of the organic material solution are not particularly limited, and can be selected from a temperature equal to or less than the boiling point of the solvent at normal pressure to subcritical and supercritical conditions of the solvent. The temperature under normal pressure is preferably -10 to 150°C, more preferably -5 to 130°C, particularly preferably 0 to 100°C.

[0127] In the present invention, the organic material must be uniformly dissolved in a good solvent, but the dissolution is preferably performed under acidic or basic conditions. Generally, alkaline conditions are used when pigments with groups that can be dissociated under basic conditions are used in the molecule, and when there are no groups that dissociate under basic conditions and there are a large number of nitrogen atoms in the molecule that are easy to add protons Use acidic conditions. For example, quinacridone compound pigments, diketopyrrolopyrrole compound pigments, a...

specific Embodiment approach

[0616] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples.

Embodiment 1

[0619]

[0620] In 1000ml of dimethyl sulfoxide (manufactured by Wako Pure Chemical Industries, Ltd.), add 33.3ml of sodium methoxide 28% methanol solution, 50g of pigment C.I. pigment red 254 (Irgaphor Red BT-CF, trade name, Chiba Specialty Chemicals Co., Ltd.) and 100.0 g of polyvinylpyrrolidone (K-30, trade name, manufactured by Wako Pure Chemical Industries, Ltd.), to prepare a pigment solution A. Separately, 1000 ml of water containing 16 ml of 1 mol / l hydrochloric acid (manufactured by Wako Pure Chemical Industries, Ltd.) was prepared as a poor solvent.

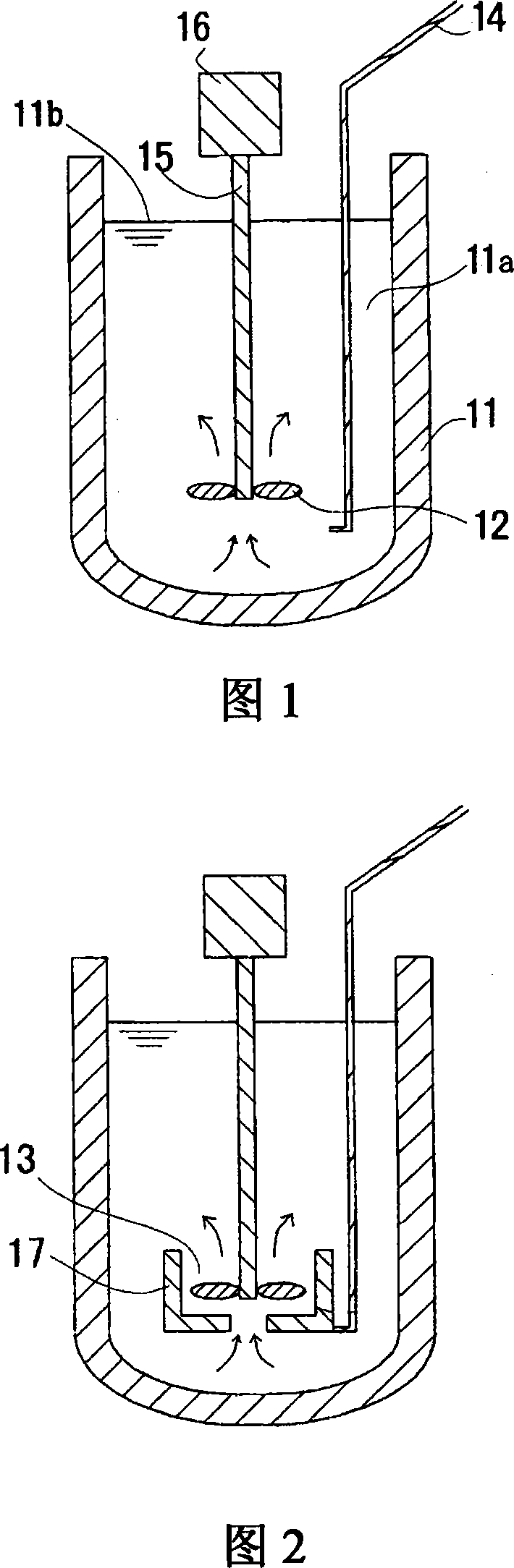

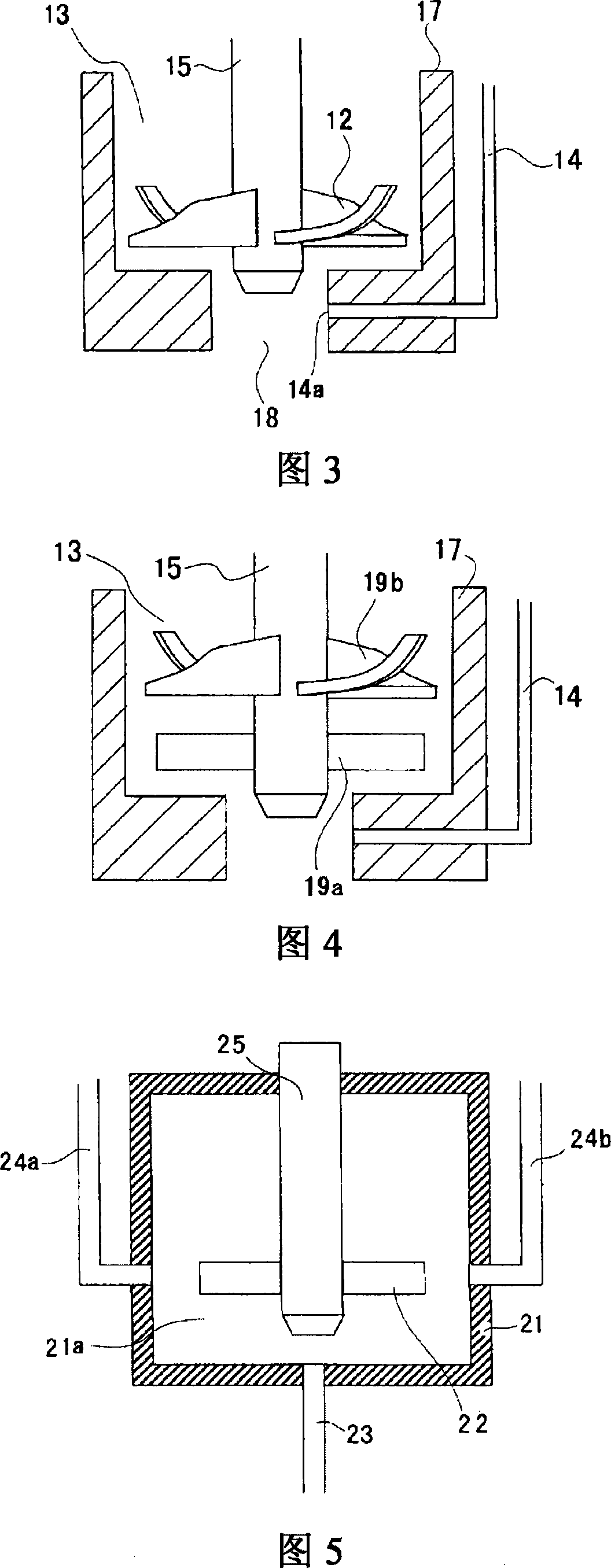

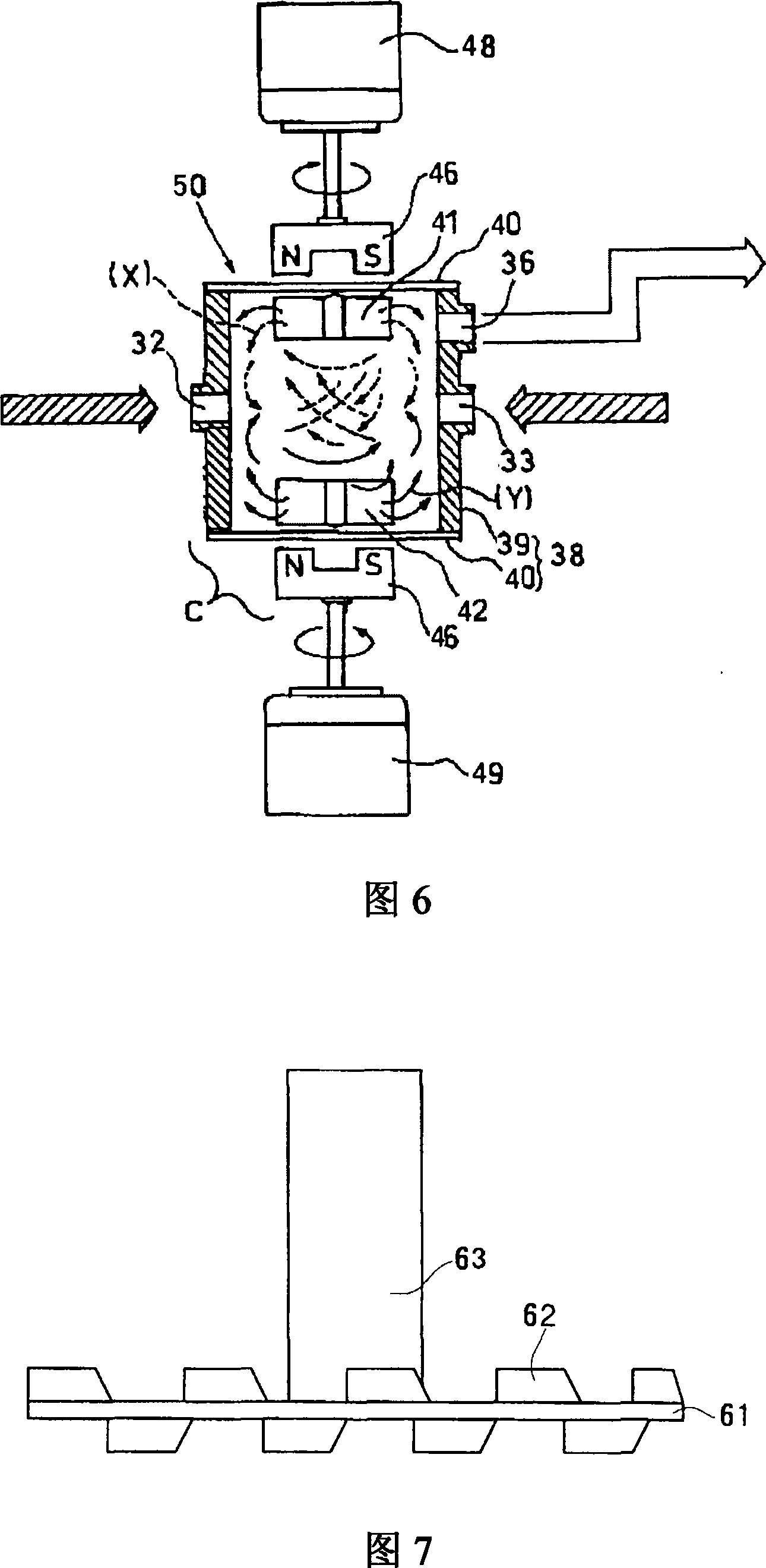

[0621] At this time, the temperature was controlled at 18° C., and in 1000 ml of poor solvent—water 1,000 ml stirred at a speed of 500 rpm by using GK-0222-10 Ramond star-ra- (trade name, manufactured by Fujisawa Pharmaceutical Co., Ltd.), - KX-500 large-capacity non-pulsation pump (trade name, manufactured by Nippon Seiko Chemical Co., Ltd.) injects 100 ml of pigment solution A at a flow rate of 100 ml / min to form or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com