Method for reclaiming metal by copper smelting-furnace magnesia brick lining

A technology for copper smelting furnace and magnesia brick, which is applied in metallurgy and chemical fields, and can solve the problems of land occupation and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

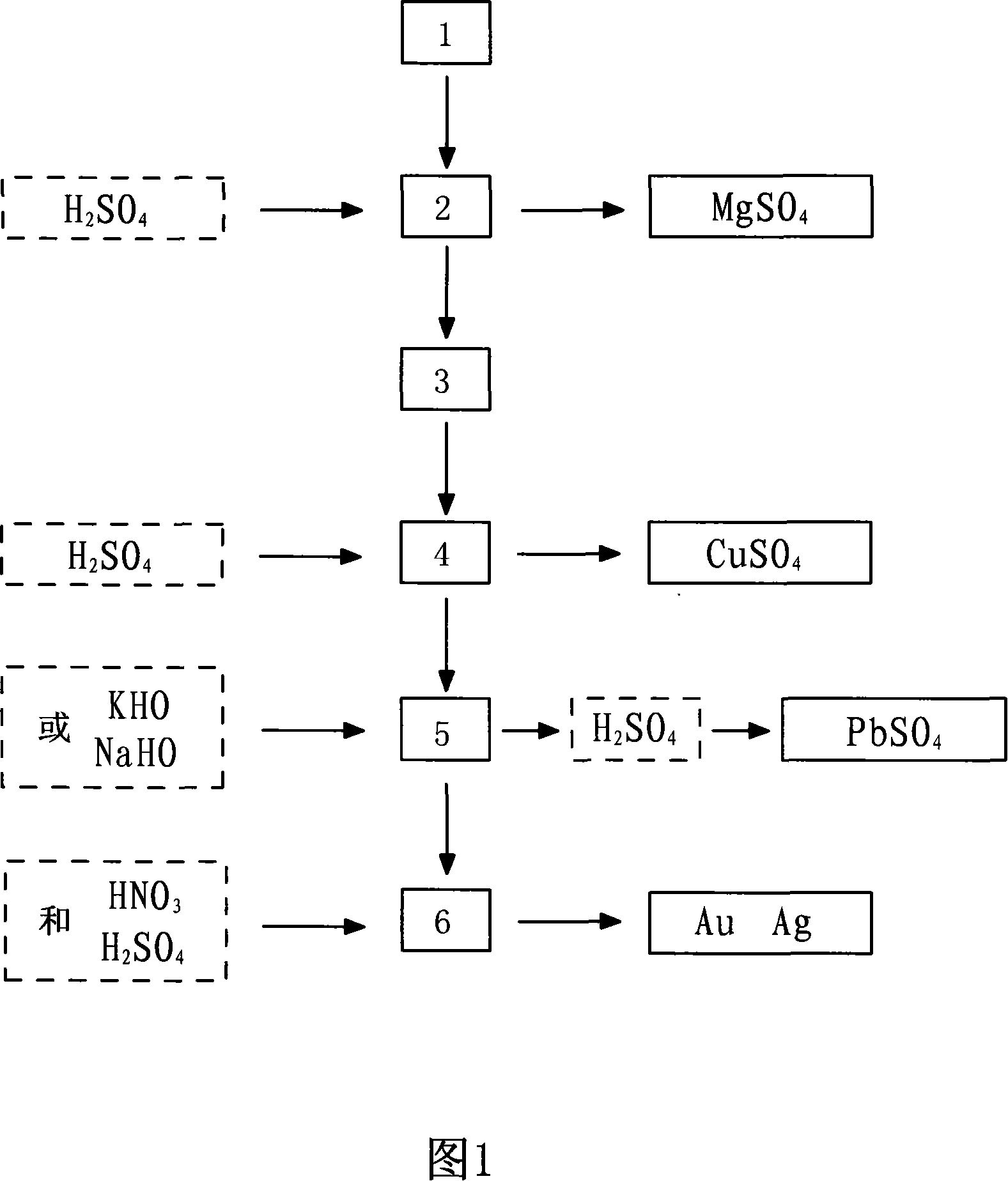

[0038] Manually randomly select 3 tons of waste magnesia bricks for copper smelting converter lining. Use a ball mill to pulverize and grind to 200 mesh, and then use the shrinkage method to sample. Chemical analysis data show that the content of copper in waste magnesia bricks is 10.3%, and the content of silver is 898μg·g -1 , the gold content is 3 μg g -1 . From these experimental results, the metals in waste magnesia bricks have recycling value. Since the magnesia content in waste magnesia bricks is between 60% and 65%, it is necessary to effectively remove magnesia for metal recovery, and then recover copper after removing magnesia, so that silver and gold can be highly enriched.

[0039] 1. Raw material crushing process:

[0040] The artificially selected magnesia refractory bricks with high metal content are crushed and ground into powder, passed through a 200-mesh sieve, and used as raw materials for metal extraction.

[0041] 2. Magnesium removal process:

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com