Minisize highly-effective thermal self-circulation cooling system for fuel cell

A fuel cell and cooling system technology, used in fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problem of reducing the weight specific power and volume specific power of the fuel cell stack system, reducing the efficiency of the fuel cell system, limiting fuel Battery use occasions and other issues, to achieve the effect of improving the overall use efficiency, environmental protection, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

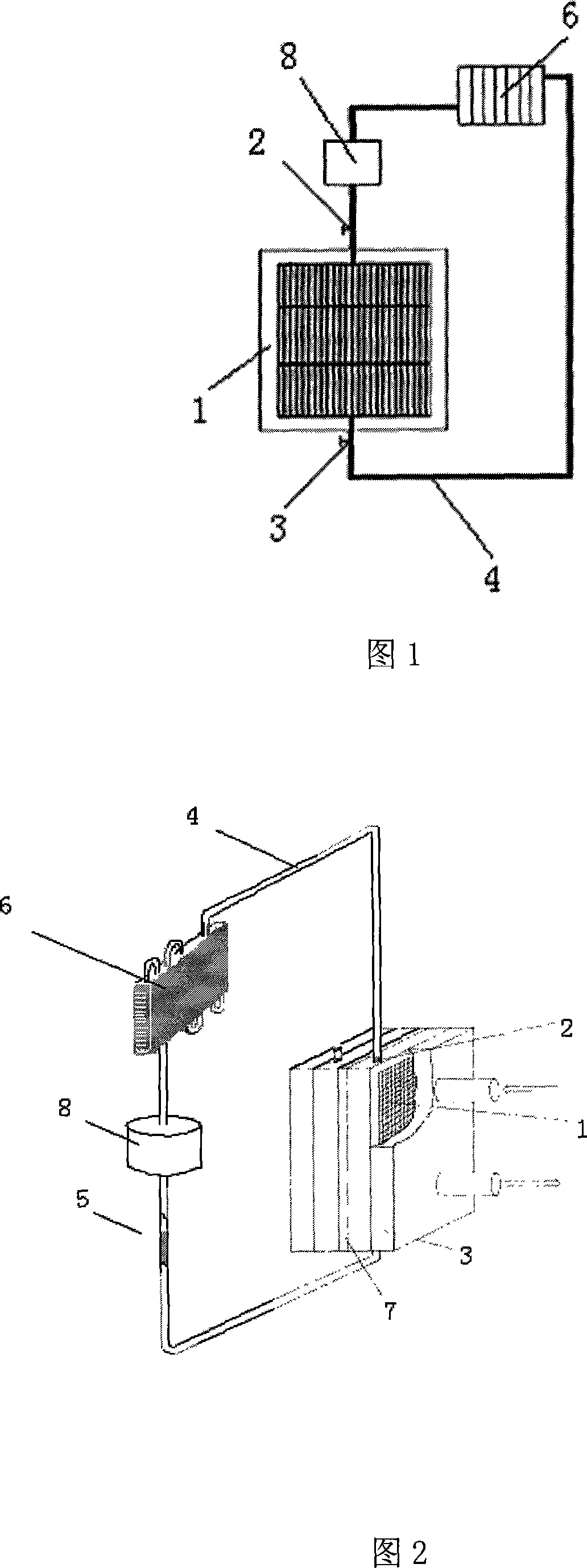

[0034] As shown in Figures 1 and 2, the fuel cell miniature high-efficiency thermodynamic self-circulation cooling system consists of a metal bipolar plate 1 with a micro-channel evaporator in the inner cavity, and a condensation pipe 4. The condensation pipe 4 passes through a unidirectional conduction function. The inlet micro-check valve 3 and the outlet micro-check valve 2 are in communication with the micro-channel, the condensing pipe 4 and the micro-channel have circulating cooling working medium 5, and the condensing pipe 4 is provided with heat-dissipating metal fins 6 and connected with a cooling Working fluid storage tank 8.

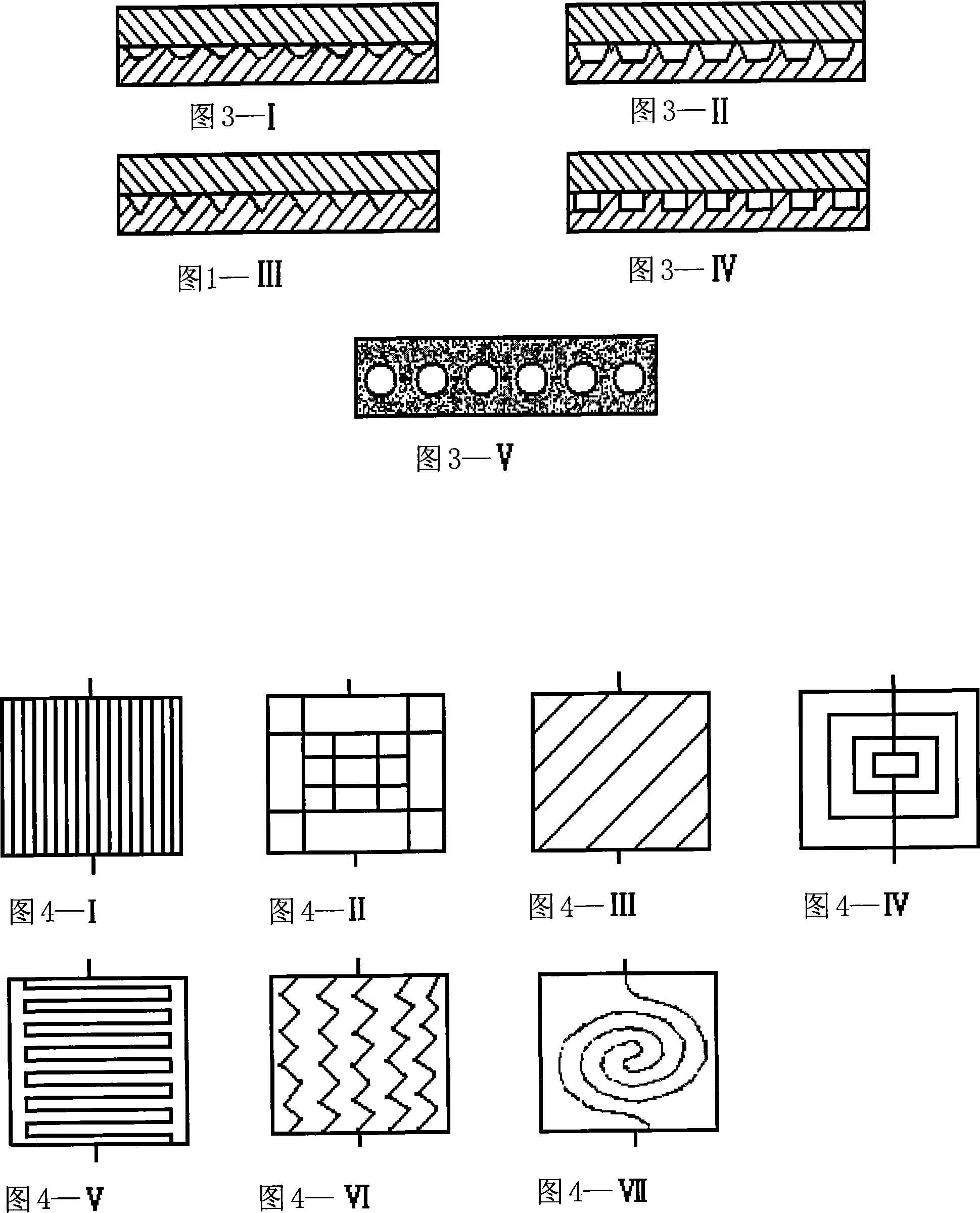

[0035] The microchannel in the inner cavity of the bipolar plate 1 is to process some micro channels with a width of 1 mm and a depth of 1 mm on the surface of a stainless steel plate, and its cross-sectional shape is square, as shown in Figure 3-IV, and then bonded with another side surface There is a combination package of stainless steel pl...

Embodiment 2

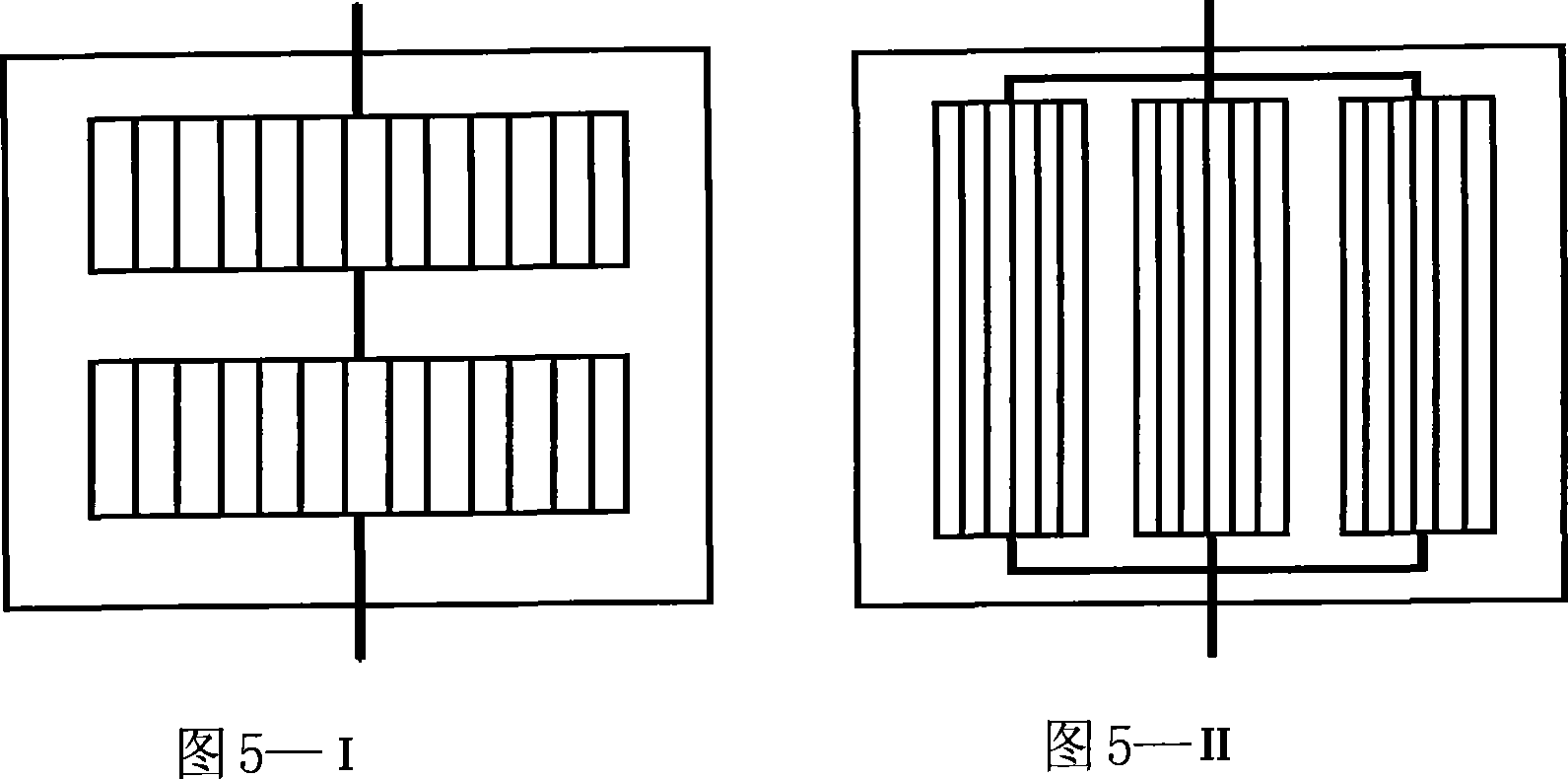

[0037]The structure of the fuel cell miniature high-efficiency thermodynamic self-circulating cooling system is the same as that of Embodiment 1. Wherein the microchannel in the inner cavity of the bipolar plate 1 is to process some microchannels with a radius of 0.5mm on the surface of an aluminum plate first, and its cross-sectional shape is shown in Figure 3-I, and the other side has a serpentine gas flow channel. The combination of the reverse side of the aluminum plate is used to seal the two plates with a silicone rubber wire. As shown in Figure 5-I, multiple groups of microchannels are connected in series through fine grooves whose cross-sectional area is 2 to 3 times the cross-sectional area of the microchannels, as shown in Figure 4-II, the arrangement of each group of microchannels adopts a well-shaped pattern. The condensation tube is a stainless steel capillary with a diameter of 3 mm and a wall thickness of 1 mm. The micro-check valve is a micro-check valve pro...

Embodiment 3

[0039] The structure of the fuel cell miniature high-efficiency thermodynamic self-circulating cooling system is the same as that of Embodiment 1. Among them, the microchannels in the inner cavity of the bipolar plate are processed on the surface of a copper plate with some micro channels with a height of 1 mm and a width of 1 mm at the bottom. The cross-sectional shape is shown in Figure 3-III. The reverse side of the red copper plate of the flow channel is combined and packaged, and the two plates are sealed with a silicone rubber wire. As shown in Figure 5-II, multiple groups of microchannels can be connected in parallel through fine grooves whose cross-sectional area is 2 to 3 times the cross-sectional area of the microchannels, as shown in Figure 4-III, the arrangement of each group of microchannels is oblique. Copper capillary with a diameter of 3 mm and a wall thickness of 1 mm was used as the condenser tube. The micro-check valve is a micro-check valve produced by L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com