Method for treating heavy metal polluted soil

A technology for polluted soil and heavy metals, applied in the field of treatment of heavy metal polluted soil, can solve the problems of high price of chemical complexing agents, lack of universality, and a large degree of restriction, and achieves reduction of ecological risks, simple facilities, and strong applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

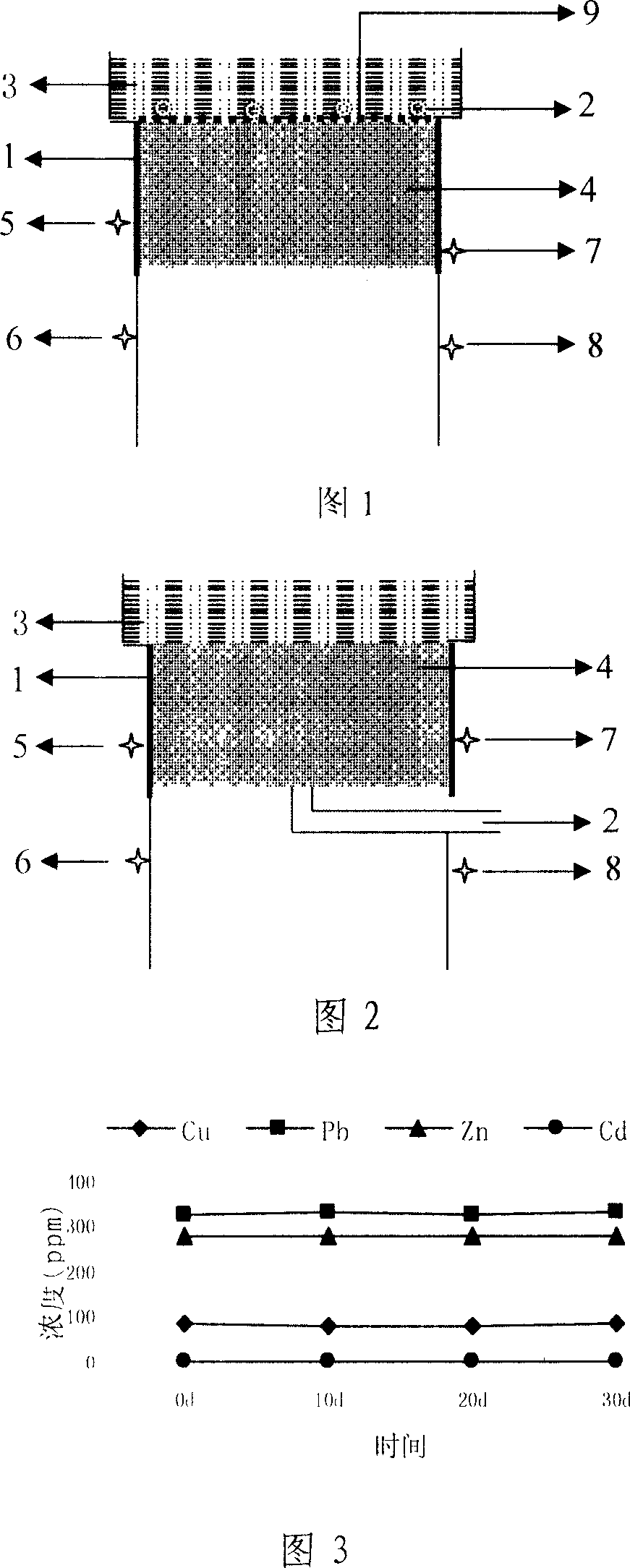

[0021] Remove the soil surface layer 3 in the heavy metal polluted area and replace the clean soil; use the isolation layer 1 to isolate the subsurface layer 4; lay underground blind pipes 2 to guide water; lay an anti-seepage film 9 between the subsurface layer 4 and the surface layer 3, The underground blind pipe 2 is arranged below the surface layer 3 and above the anti-seepage membrane 9 for guiding and draining surface water.

[0022] Specific implementation method (see Figure 1):

[0023] 1. The physical method of the concrete structure used in isolation layer 1 is: use concrete to build a 2m long, 2m wide, and 1m high cement pool. The height of the top of the cement pool from the ground is 0.5m, and the bottom is not closed.

[0024] 2. Cover the subsurface layer 4 contaminated soil with a height of 1.0m at the bottom of the cement pool, and the soil compactness is close to the density of the original contaminated soil; the concentrations of the original soil pollutants...

Embodiment 2

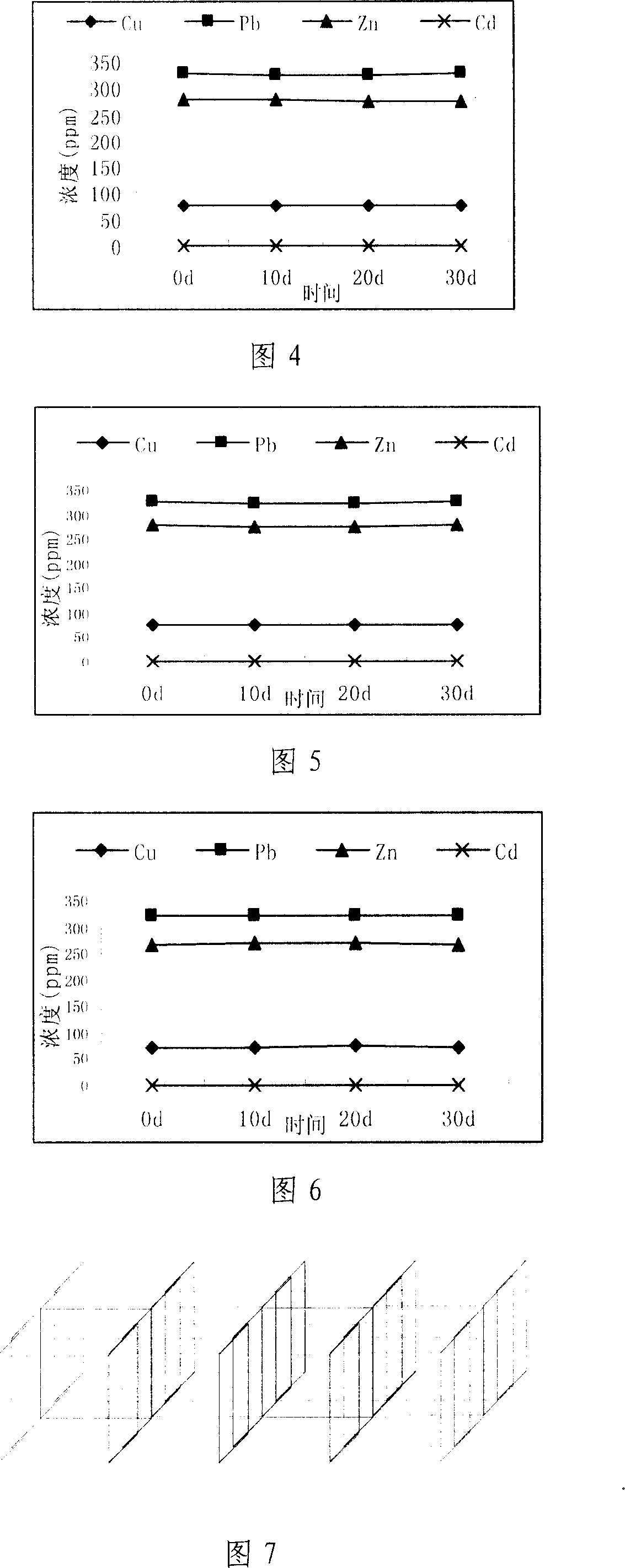

[0031] The difference from Example 1 is that there is no anti-seepage film 9 between the surface layer 3 and the subsurface layer 4, and the underground blind pipe 2 is arranged below the subsurface layer 4 for guiding and draining the percolation water, and the collected percolation water Discharge after centralized sedimentation treatment to remove pollutants, see Figure 2.

[0032] After leaching, soil samples and soil infiltration water at each monitoring point were collected every 10 days, and the concentration of heavy metals was determined by inductively coupled plasma atomic emission spectrometer (ICP).

[0033] The measurement results are: 1#, 2#, 3# and 4# monitoring points soil heavy metal content basically unchanged, the concentrations of Cu, Pb, Zn and Cd are all around 80.0, 326.0, 278.0 and 0.7ppm. The concentrations of Cu, Pb, Zn and Cd in the underground leachate after precipitation treatment were all lower than 1.0, 2.0, 0.1 and 0.01ppm (see Table 1), indicat...

Embodiment 3

[0037] The difference from Example 1 is that in order to improve the treatment effect, 3% lime, a pollutant fixing agent, can be added to the encapsulated and sealed subsurface contaminated soil.

[0038] The monitoring results show that the heavy metal-contaminated soil will not pollute the groundwater and the surrounding environment after continuous leaching treatment after encapsulation, restoration and treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com