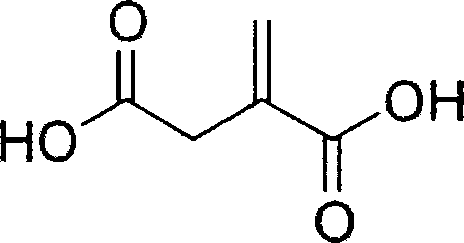

Method for purifying itaconic acid fermentation liquor or extracting itaconic acid from itaconic acid mother liquid by film device

A technology of itaconic acid mother and itaconic acid, which is applied in the field of membrane separation technology and itaconic acid preparation, can solve the problems of pollution, waste of resources and the environment, reduce production costs, avoid secondary pollution, and increase the total yield of extraction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Get the mother liquor 250L that contains itaconic acid 171.6 g / L, adopt the nanofiltration membrane that average molecular weight cut-off (10,000 Daltons) is 200 and 500 to process it respectively, when residual liquid is 30L (concentration factor is 8.33), Continuously add tap water to maintain the volume of the residual liquid at about 30L. During the operation, the temperature is controlled at 35-45°C. Finally, the filtrate is concentrated, crystallized, decolorized, and recrystallized. The results are as follows:

[0027]

Test batch number

Membrane average molecular weight cut off

(Wandalton)

Water volume (L)

Membrane filtration yield

total yield

1

200

50

96.4%

92.1%

2

200

75

97.8%

93.4%

3

500

50

97.3%

92.5%

4

500

75

98.5%

93.8%

[0028] Note: Membrane filtration yie...

Embodiment 2

[0031] Get 250L of fermented liquid that contains itaconic acid 73.2g / L, adopt the nanofiltration membrane that average molecular weight cut-off (10,000 Daltons) is 200 and 500 to process it respectively, when residual liquid is 15L, add deionized water continuously (or ordinary industrial water) to maintain the volume of the residual liquid at about 15L, control the temperature at 35-45°C during the operation, and finally concentrate the filtrate for crystallization, decolorization, and recrystallization. The results are as follows:

[0032]

Embodiment 3

[0034] Get the fermented liquid that contains itaconic acid 80g / L, after filtering to remove bacteria, adopt the ultrafiltration membrane that average molecular weight cut-off (10,000 Daltons) is 2000 and 3000 to process it respectively, when residual liquid is 20L (concentration times When it is 12.5), add deionized water (or common industrial water) continuously to maintain the volume of the residual liquid at about 20L. During the operation, the temperature is controlled at 35-45°C. Finally, the filtrate is concentrated, crystallized, decolorized, and recrystallized. The result is as follows:

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com