Highly anti-corrosive thin platelet-like metal pigments, preparing method of the same, and colored interference pigments having metallic luster based on the same

A technology of metallic pigments and metallic luster, applied in the direction of fibrous fillers, etc., can solve the problems of irregular reflection, insufficient particle dispersion, deterioration, etc., and achieve good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

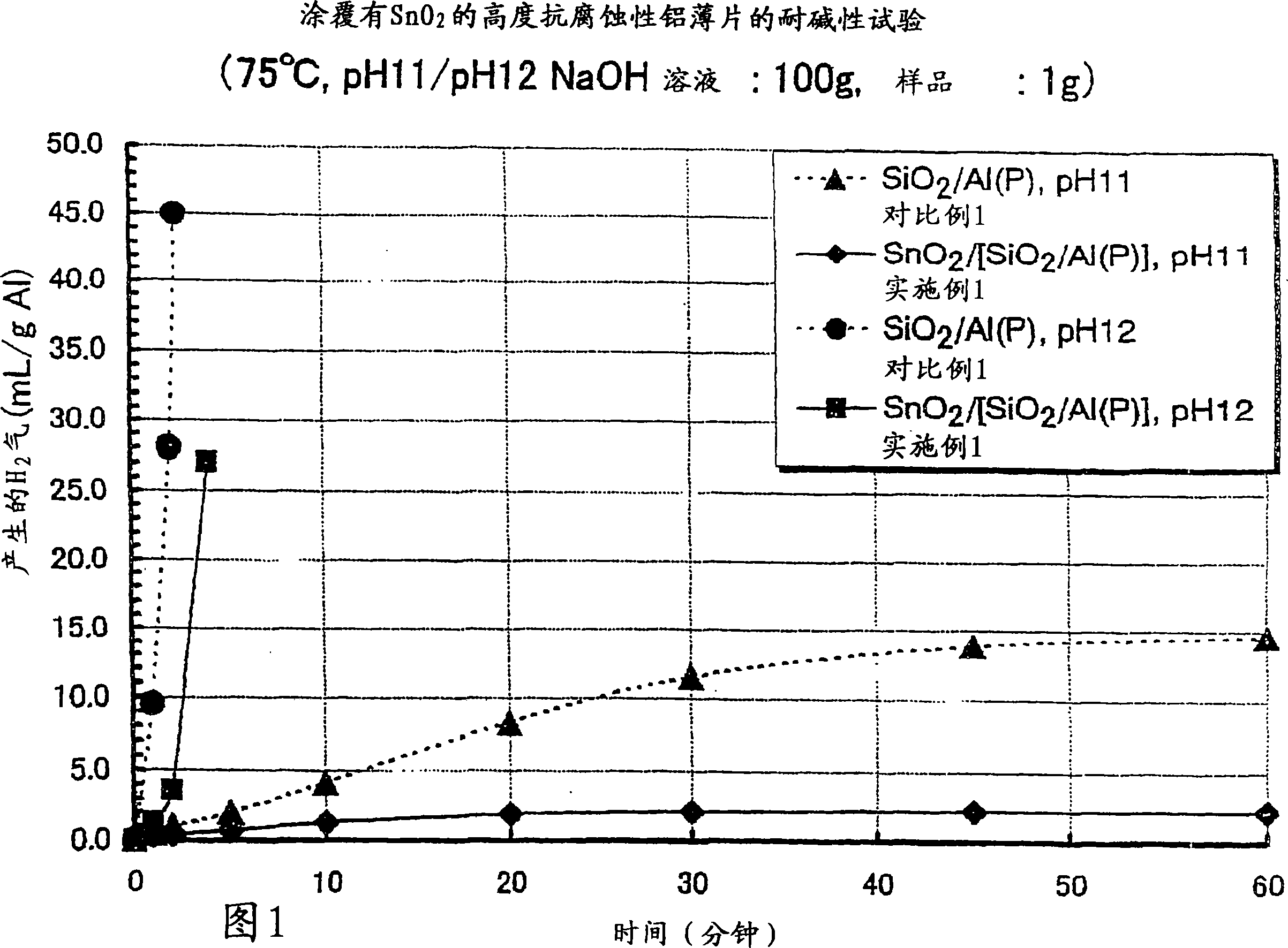

[0145] Highly corrosion-resistant flake metallic pigments (SnO 2 / [SiO 2 / Al(P)]) preparation

[0146] With 100 grams of its layer through anticorrosion-treated flake metal substrate (according to the [SiO 2 / Al(P)], specific surface area: 3.01m 2 / g) suspended in 2 liters of water. The suspension was heated to 75°C with stirring. 372 ml of SnCl 4 5H 2 O solution (concentration 50 g / l) was added dropwise to the suspension while maintaining the pH at 1.8 with 32% by weight aqueous sodium hydroxide solution. Afterwards, the solid part filtered from this suspension was washed and dried to obtain highly corrosion-resistant flaky metallic pigments (SnO 2 / [SiO 2 / Al(P)]). With the per unit surface area (m) of the sheet metal substrate (Al) 2 ) of tin oxide (SnO 2 ), the amount of the coating layer of hydrated tin oxide is an amount corresponding to 0.036 g.

Embodiment 2

[0154] Embodiment 2: have the color interference pigment (Fe 2 o 3 / SnO 2 / [SiO 2 / Al(P)]) preparation

[0155] 50 grams of highly corrosion-resistant flake metal pigments (SnO 2 / [SiO 2 / Al(P)]) suspended in one liter (litter) of water. The suspension was heated to 75°C with stirring. Thereafter, the pH was adjusted to 3.0 using aqueous hydrochloric acid / sodium hydroxide solution. In addition, drop 1816 grams of FeCl 3 (III) Aqueous solution (concentration: 30 g / l) until the desired hue is obtained while maintaining the pH at 3.0 using aqueous sodium hydroxide solution. The mixture was further washed / filtered, dried, and calcined at 350° C. for 30 minutes to obtain a color interference pigment with a reddish metallic luster.

Embodiment 3

[0156] Embodiment 3: the color interference pigment (TiO with metallic luster) 2 / SnO 2 / [SiO 2 / Al(P)]) preparation

[0157] 50 grams of highly corrosion-resistant flake metal pigments (SnO 2 / [SiO 2 / Al(P)]) suspended in one liter of water. The suspension was heated to 75°C with stirring. Afterwards, the pH was adjusted to 1.8 using aqueous hydrochloric acid / sodium hydroxide solution. Then, titanium tetrachloride solution (TiCl 4 , Concentration: 448 g / L) was added dropwise to this suspension until the desired hue was obtained, while maintaining the pH at 1.8 using 32 wt% aqueous sodium hydroxide solution to complete the reaction in a green hue. The mixture was further filtered to remove the solid part, washed, dried and calcined (30 minutes at 350° C.) to obtain a metallic luster colored interference pigment (TiO 2 / SnO 2 / [SiO 2 / Al(P)]).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com