Sheet combination type structure of photocatalyst carrier

A photocatalyst, combined technology, used in catalyst carriers, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as being unable to be irradiated by ultraviolet light, small effective surface area, and no longer able to provide surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

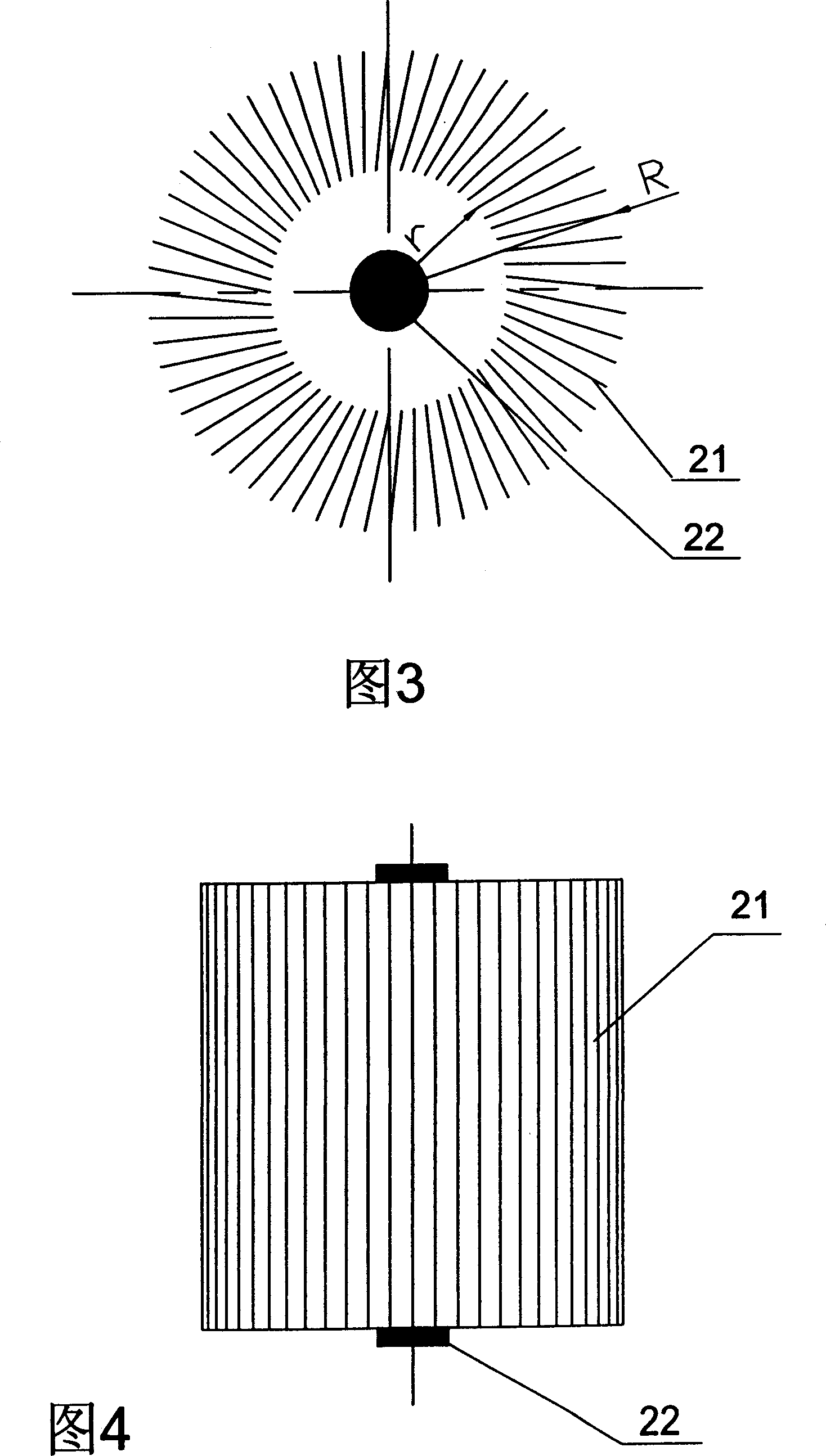

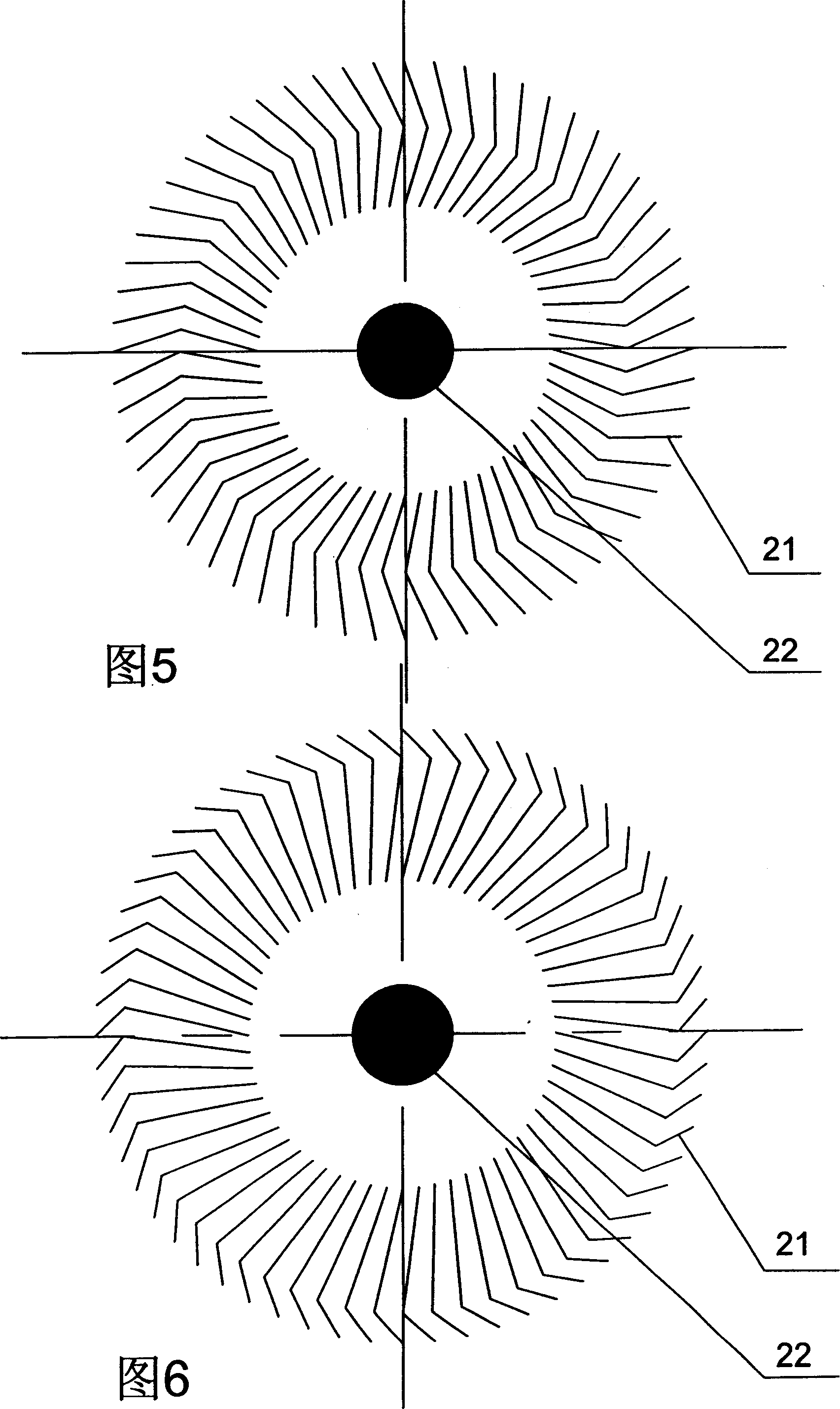

[0036] Please refer to Fig. 3, shown in Fig. 4 first, thin-plate combined type photocatalyst carrier structure of the present invention comprises several thin plates 21, ultraviolet light source 22,

[0037] The several thin plates 21 are arranged and assembled together around the ultraviolet light source 22 according to a certain geometric shape, the ultraviolet light source 22 is located at the central position of the determined geometric shape, and the surface of each thin plate 21 is equipped with a photocatalyst, between each thin plate 21 A certain angle is staggered along the circumferential direction, so that gaps are formed between the thin plates 21 for fluid to flow in these gaps.

[0038] In the examples shown in Fig. 3 and Fig. 4, it can be seen that the thin plate 21 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com