Oxidizing reactor in bubbling tower of internal circulation for producing aromatic acid

An oxidation reactor and internal circulation technology, applied in chemical instruments and methods, organic chemistry, carboxylate preparation, etc., can solve problems affecting reaction efficiency, complex internal structure of reactor, low oxygen concentration, etc., and achieve good application prospects , Improve the axial oxygen concentration gradient and promote the effect of material circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

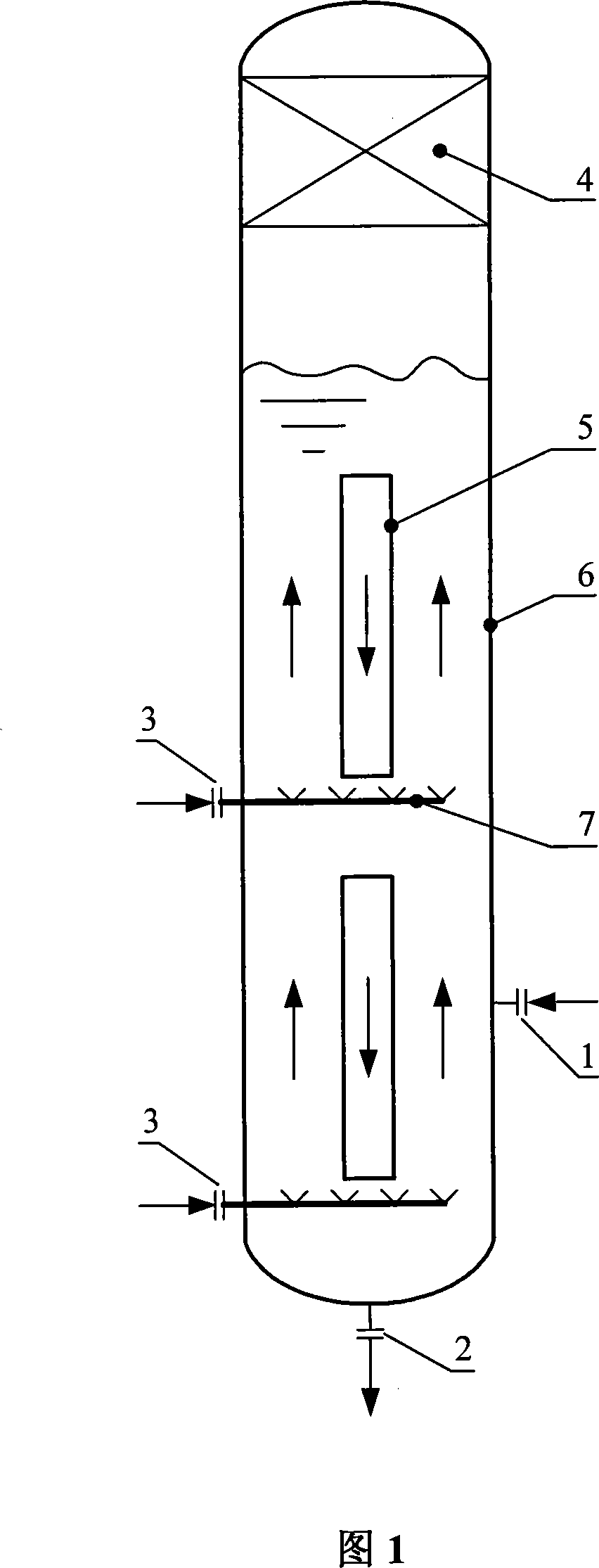

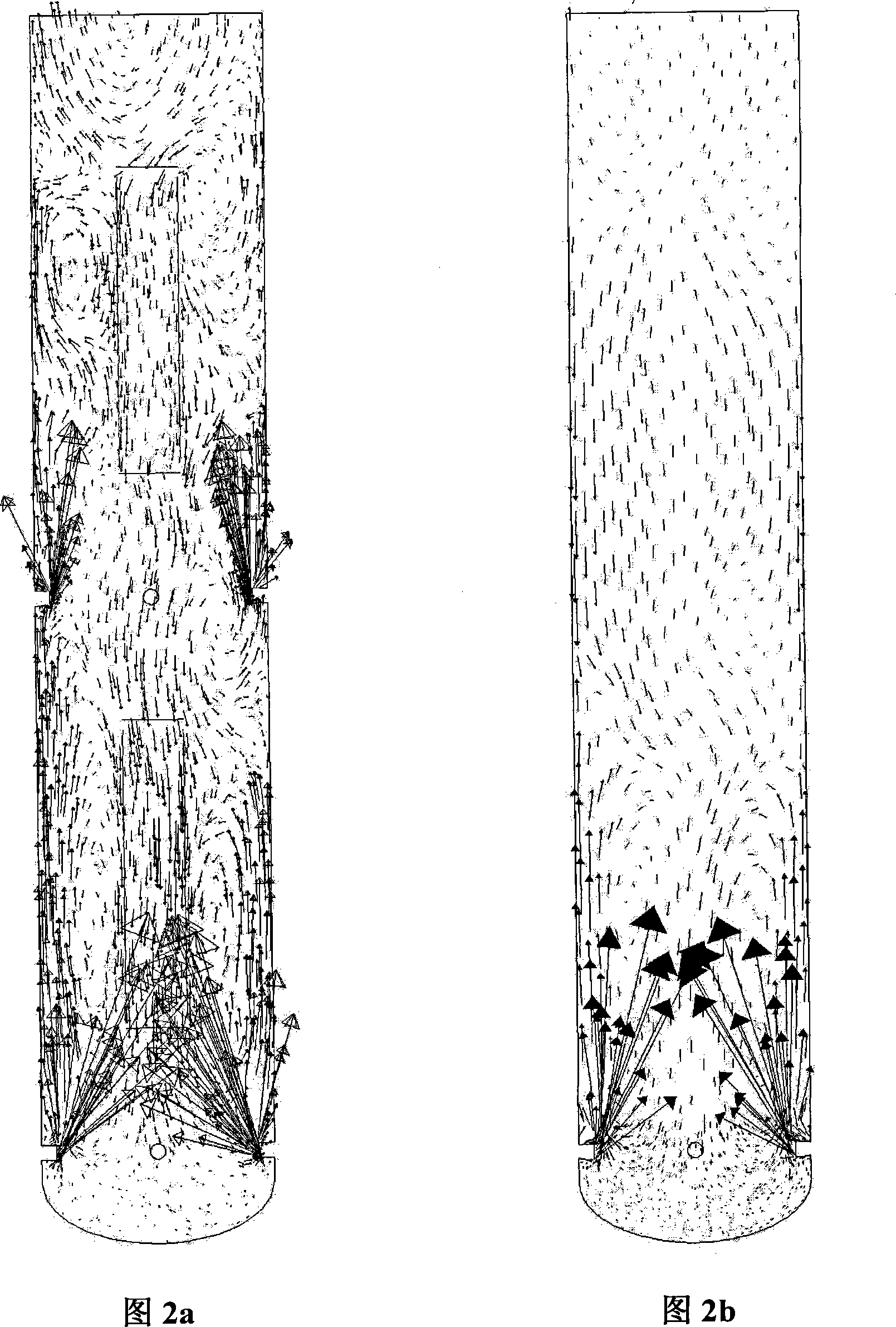

[0019] In a conventional bubble column oxidation reactor, after the gas enters the reactor through the gas distributor at the bottom of the reactor, the bubbles continue to rise, coalesce, and grow up, forming large-diameter bubbles in the upper and middle parts of the reactor. Higher apparent gas holdup, but the gas-liquid interface area and gas-liquid mass transfer capacity are not as good as the middle and lower parts of the bubble column reactor. On the other hand, inside the bubble column without internal components, the liquid phase flow is chaotic, and there is a concentration difference in the height direction of the column, and the inlet and outlet of the liquid and solid phase materials are generally set in the lower section of the column, resulting in a lower reaction efficiency in the upper part of the bubble column. For bubble columns with a large aspect ratio, the above problems are more prominent.

[0020] The present invention adopts the method of rationally ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com