Method for continuously preparing spray strengthened aqua compound and device thereof

A preparation device and technology for hydrates, applied in chemical instruments and methods, chemical methods for reacting gaseous media with gaseous media, and methods for chemically changing substances by using atmospheric pressure, etc., can solve the problem of small gas-water contact area, etc. problem, to achieve the effect of increasing the nucleation rate, promoting dissolution, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

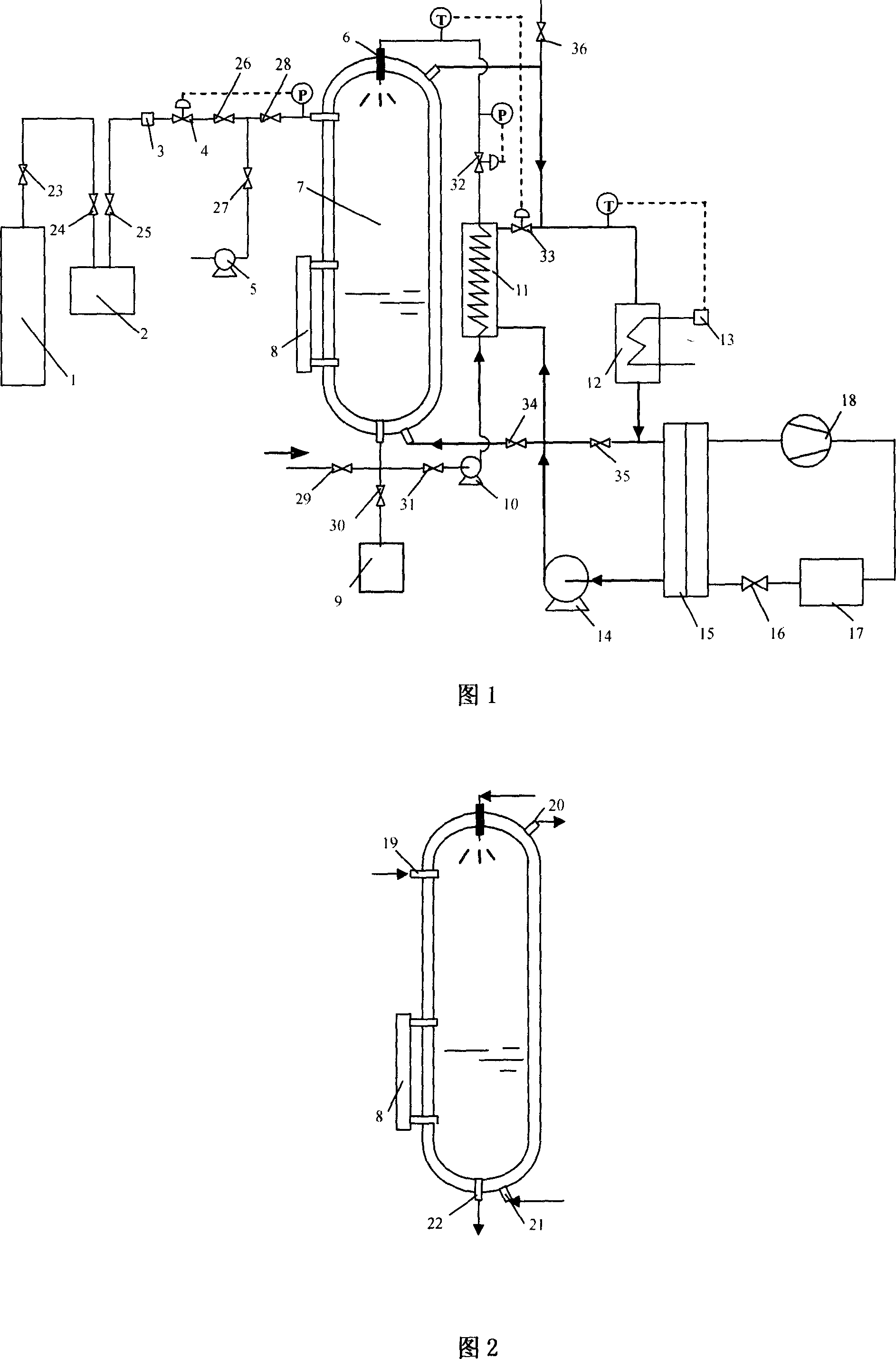

[0018] Before hydrate preparation, open valve seven 29, close valve eight 30, and valve nine 31, add an appropriate amount of water to reactor 7, determine the height of the water level through water level gauge 8, close valve seven, and open valve nine. Open valve 5 28 and valve 6 29, use vacuum pump 5 to evacuate the reactor to remove dissolved gas in water, and after realizing the vacuum degree requirement of the reactor, turn off valve 5 of the connecting pipeline of the vacuum pump. According to the phase equilibrium condition of hydrate formation, set the pressure control value of the decompression control valve 4, open valve one 23, valve two 24, valve three 25, valve four 26, and the gas enters the buffer tank 2 from the gas cylinder 1 through the pipeline , to keep the gas pressure stable during the hydrate preparation process, and enter the reactor 7 through the filter 3 and the decompression control valve 4 . The pressure signal on the intake pipeline controls the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com