Hickory nut husk disinfectant and its producing method

A production method and exocarp technology, applied in the field of botanical pesticides, can solve the problems of undiscovered, poor economic benefits, etc., and achieve the effect of reducing secondary pollution and benefiting environmental protection and human and animal health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: The pecan exocarp was dried to a water content of 9%, crushed into a 50-mesh powder, and weighed 500 kg of crushed matter; extracted with 1500 kg of methanol in a reflux extraction kettle at a temperature of 70° C. for 8 hours, and centrifuged to obtain The extract is then vacuum-concentrated until the concentrated solution is close to 500kg, and then 500kg of the extract is obtained for subsequent use.

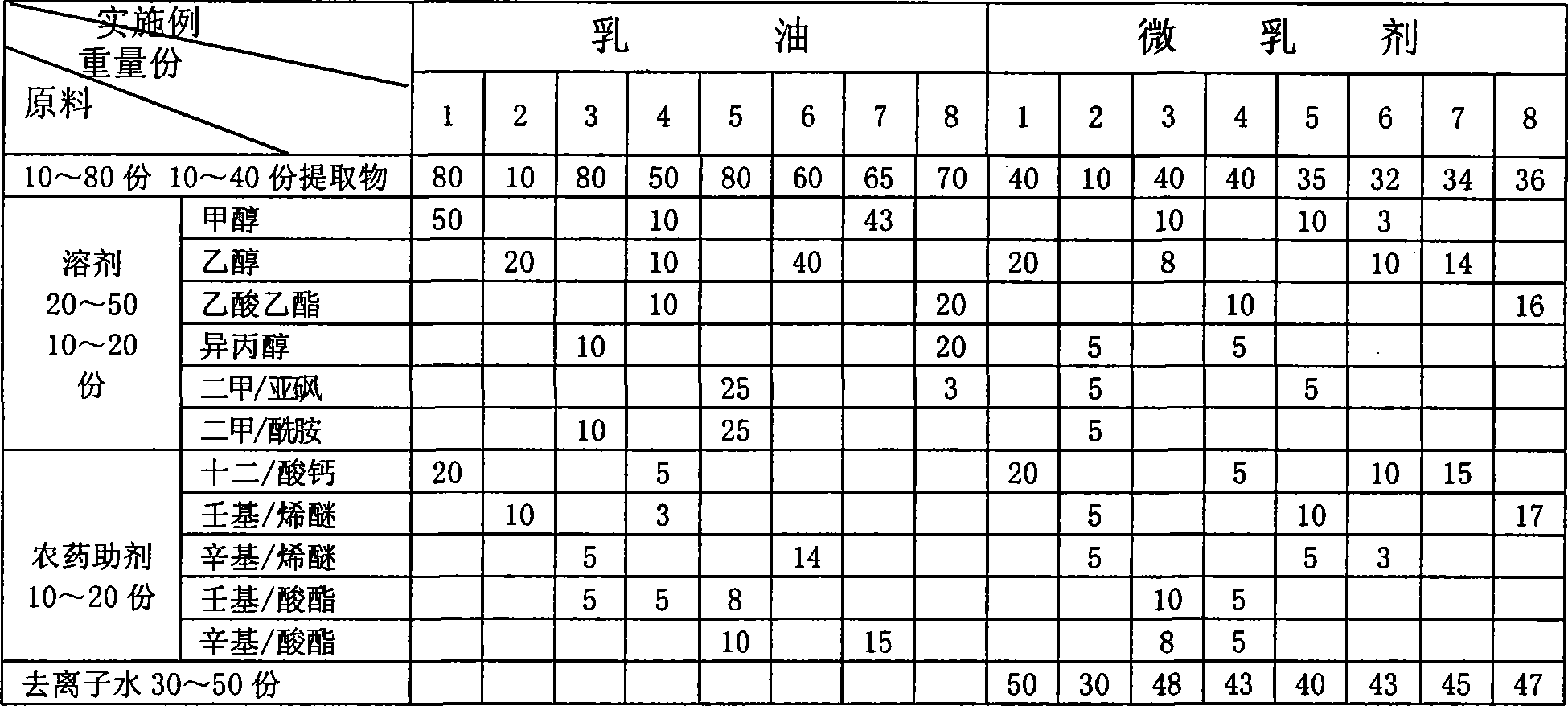

[0027] According to the raw materials corresponding to Example 1 in Table 1 and the proportions by weight thereof, bactericide emulsifiable concentrate or microemulsion bactericide were respectively prepared.

[0028] Example 1 in comparison table 1 prepares fungicide emulsifiable concentrate: with the extract of 80kg above-mentioned making, 50kg methyl alcohol, 20kg calcium laurate, 50kg deionized water, first three are joined in 50kg deionized water earlier, constant temperature Stir for 1h and serve.

[0029] Example 1 in contrast table 1 prepares microe...

Embodiment 2

[0030] Embodiment 2: the hickory nut exocarp is dried to a moisture content of 10%, is ground into 40 order powder, and weighs 500 kg of pulverized matter; with ethanol 1500 kg, extracts under 75 ℃ of temperature conditions, all the other are identical with embodiment 1 method, Concentrate at last to obtain 500kg of extract for subsequent use. Contrast the corresponding raw material of Example 2 in Table 1 and the weight parts thereof respectively with the method (high-speed stirring, temperature 40 ℃) identical with Example 1 to prepare bactericide emulsifiable concentrate or microemulsion bactericide.

Embodiment 3

[0031] Embodiment 3: the pecan exocarp is dried to a moisture content of 7%, crushed into 60 mesh powder, and weighed to obtain 1000kg of pulverized matter; 3000kg of ethyl acetate is used as an extraction solvent, extracted at a temperature of 80°C, and the rest are carried out Example 1 method is the same, finally concentrated to obtain 1000kg stock solution of extract for subsequent use. Contrast the raw materials corresponding to Example 3 in Table 1 and the proportioning by weight thereof, and use the same method as Example 1 (high-speed stirring, temperature 50° C.) to prepare bactericide emulsifiable concentrate or microemulsion bactericide.

[0032] With the above-mentioned three embodiments, the remaining five embodiments can be deduced according to the proportions in Table 1, and will not be listed one by one.

[0033] When preparing the extract, in addition to selecting a good extraction solvent from factors such as cost and the performance of dissolving effective s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap