Method for preparing active carbon

A technology of activated carbon and charcoal, used in chemical instruments and methods, special forms of dry distillation, inorganic chemistry, etc., can solve problems such as complex processes, and achieve the effects of strong decolorization power, strong adsorption capacity, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

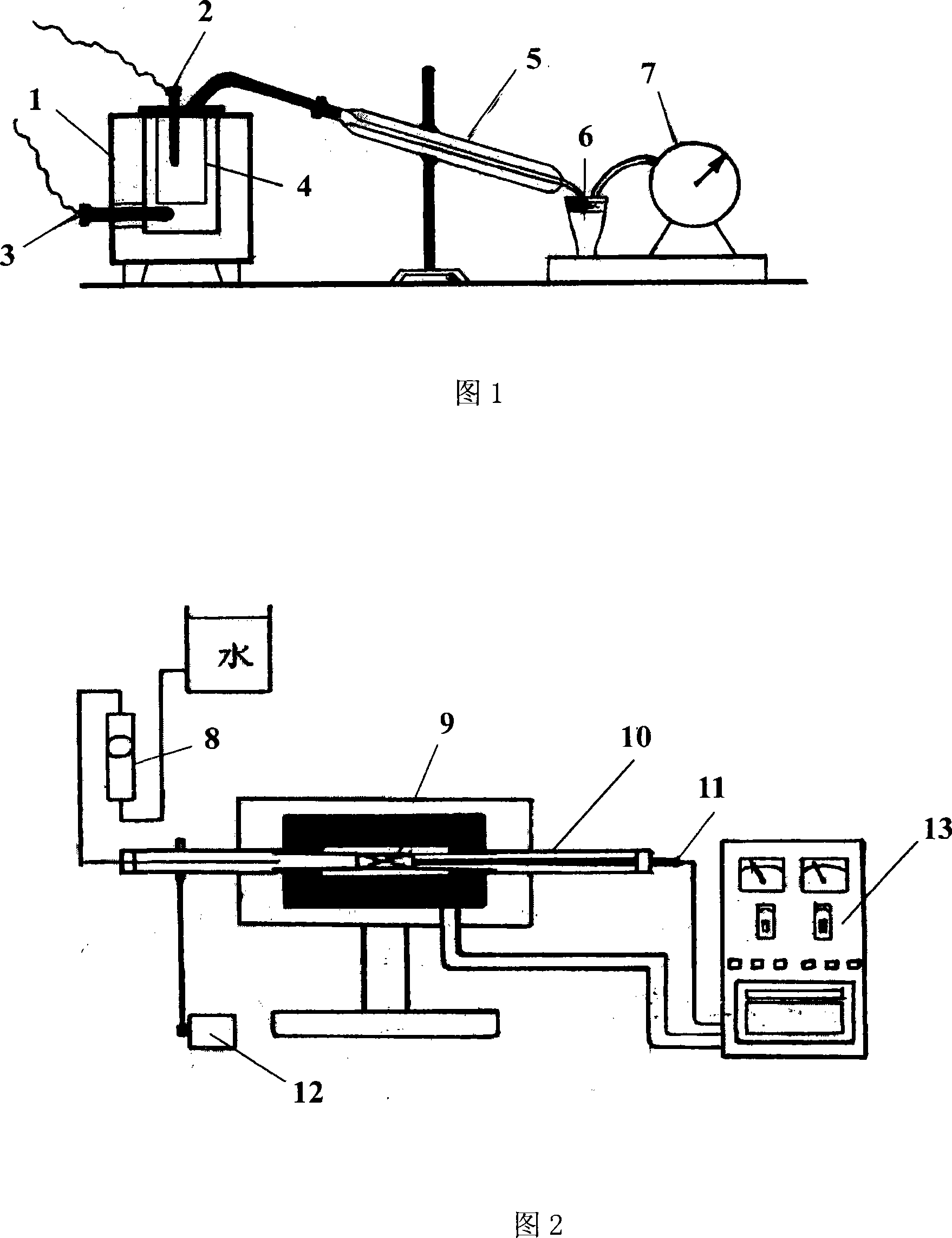

[0028] As shown in Figures 1 and 2, the preparation of activated carbon by the method of the present invention adopts a wood carbonization device and an activation device to prepare,

[0029] Specific steps are as follows:

[0030] 1. Split the ginkgo wood into 25cm, 2cm wide, and 0.5cm thick wood chips for sufficient carbonization;

[0031] 2. Weigh 0.5 kg of ginkgo wood chips and put them into the retort 4 of the wood carbonization device, then put the retort 4 into the carbonization furnace 1, insert the thermocouples 2 and 3 connected to the power supply, as shown in Figure 1, through the thermoelectric Couples 2 and 3 respectively measure the temperature inside and outside the retort 4 so as to control the temperature of the retort 4 .

[0032] The carbonization furnace 1 is connected with a gas flow meter 7 and a liquid collection and metering device 6. Through the gas flow meter 7, the gas generated during the wood carbonization process can be seen. There is no gas gen...

Embodiment 2

[0040] Except that in step 4, when the activation temperature reaches 850° C., the water vapor supply is controlled to be 100 ml, and the activation time is controlled to be 40 min, the others are the same as in Example 1.

Embodiment 3

[0042] Except that the carbonization temperature in step 2 is controlled at 500°C, the water vapor supply in step 4 is 140ml, and the activation time is 40min, the rest is the same as that of Example 1.

[0043] Its quality index of the ginkgo activated carbon that embodiment one to three prepares is as table 1.

[0044] Table 1

[0045] Quality Index

Iodine adsorption value

(mg / g)

Methylene blue decolorization power

(ml / 0.1g)

Activation yield (%)

Embodiment one

Embodiment two

Embodiment three

1072.30

1084.30

1074.09

14

14

14

33.5

35.8

32.8

[0046] Among them, the determination method of methylene blue adsorption value adopts GB / T 12496.10-1999; the determination method of iodine adsorption value adopts GB / T 12496.8-1999; the activation yield is calculated by the following formula:

[0047] Activated carbon yield (%)=(activated charcoal amount / charcoal am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com