Long wave ultraviolet excitation white luminous material and its preparation and application

A luminescent material and ultraviolet technology, applied in the directions of luminescent materials, the use of gas discharge lamps, chemical instruments and methods, etc., can solve the problems of magnesium stability and growth temperature difference, difficulty in magnesium doping, etc. The process is easy to operate, and the raw materials are cheap and easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 0.02mol ZnS and 0.002mol MgCl 2 (The molar ratio of zinc source and magnesium source is 1:0.1); Grind in fume hood for 30-40 minutes to obtain a precursor; put the gained precursor in a muffle furnace for sintering at 950-1050°C for 1-2 hours; grind for 5 In ~10 minutes, a long-wave ultraviolet-excited white light-emitting material is obtained, the composition of which is ZnO:xMg, x=0.1.

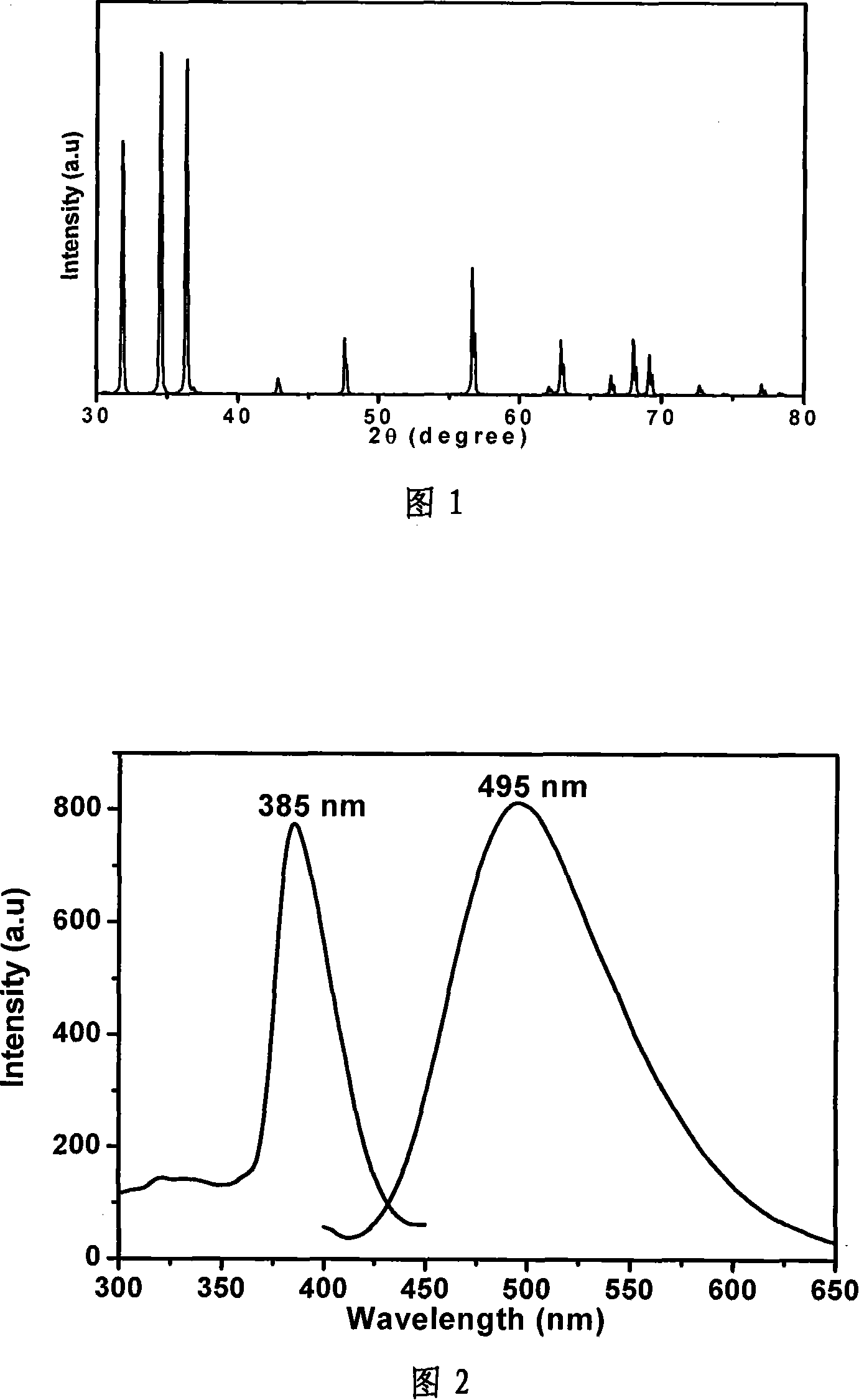

[0024] The XRD pattern of the obtained sample (test conditions are: voltage 40kV, current 40mA, scan speed 8° / min) shows that: the main phase of the sample is zinc oxide, that is, the obtained luminescent material is based on zinc oxide as the matrix (see Figure 1) .

[0025] The fluorescence spectrogram of gained sample (test condition is: λ ex =385nm,λ em = 495nm, slit width 5nm, voltage 480V, scanning speed 600nm / min) shows that: the luminescent material has strong absorption in the long-wave ultraviolet region of 385-395nm, and has strong emission at 450-600nm (see Figure...

Embodiment 2

[0027] Weigh 0.02mol ZnS and 0.001mol MgCl 2 (The molar ratio of zinc source and magnesium source is 1: 0.05); Grinding in the fume hood for 30-40 minutes to obtain a precursor; putting the gained precursor in a muffle furnace for sintering at 950-1050° C. for 1-2 hours; grinding for 5 In ~10 minutes, a long-wave ultraviolet-excited white light-emitting material is obtained, the composition of which is ZnO:xMg, x=0.05.

Embodiment 3

[0029] Weigh 0.02mol ZnS and 0.0002mol MgCl 2 (The molar ratio of zinc source and magnesium source is 1: 0.01); Grinding in fume hood for 30-40 minutes to obtain a precursor; putting the gained precursor in a muffle furnace for sintering at 950-1050° C. for 1-2 hours; grinding for 5 In ~10 minutes, a long-wave ultraviolet-excited white light-emitting material is obtained, the composition of which is ZnO:xMg, x=0.01.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com