Method for manufacturing wet fuel by rapid common thermal decomposition of biomass and coal

A technology for liquid fuels and biomass raw materials, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, etc., can solve the problems of coal and biomass failing to find synergistic effects and difficult to occur synergistic reactions, and achieve easy energy balance, ecological and The effect of good environmental benefit and strong adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

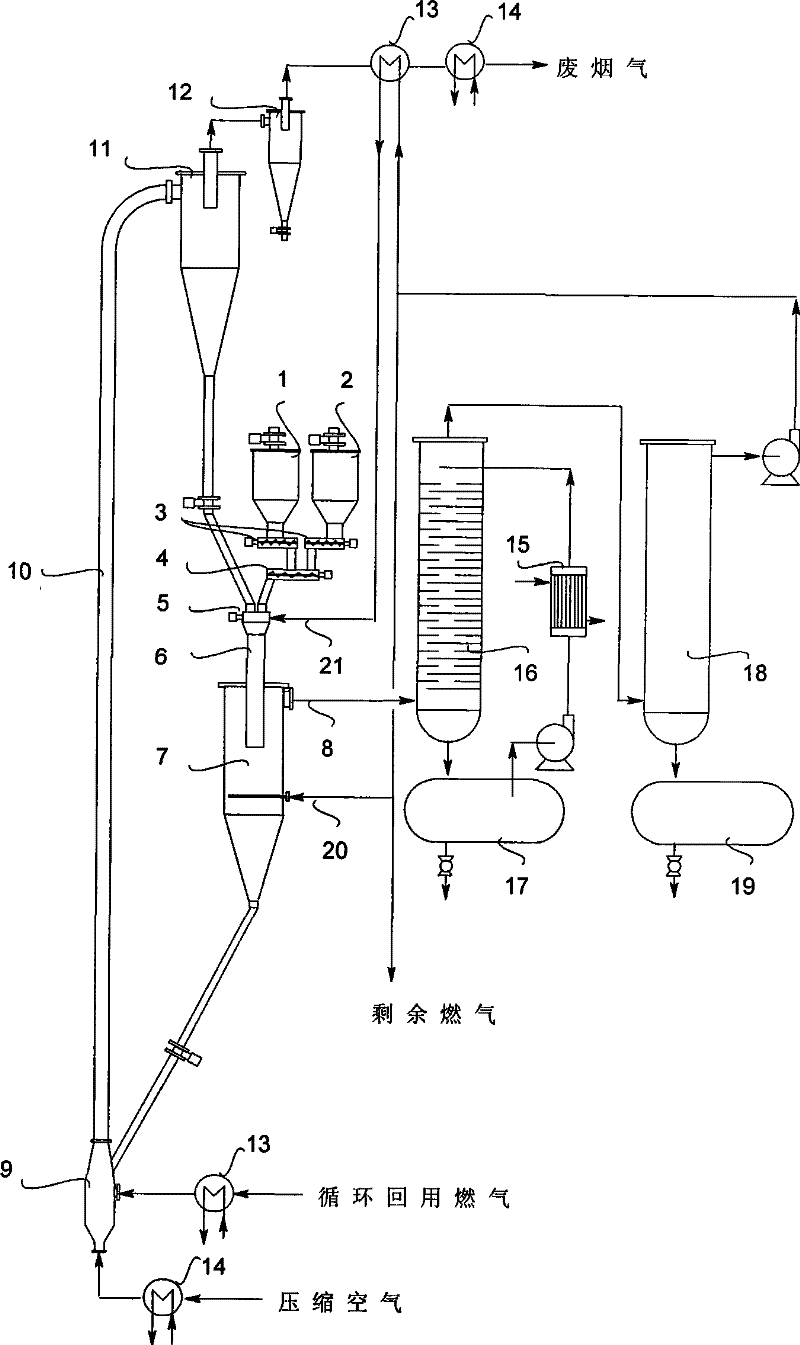

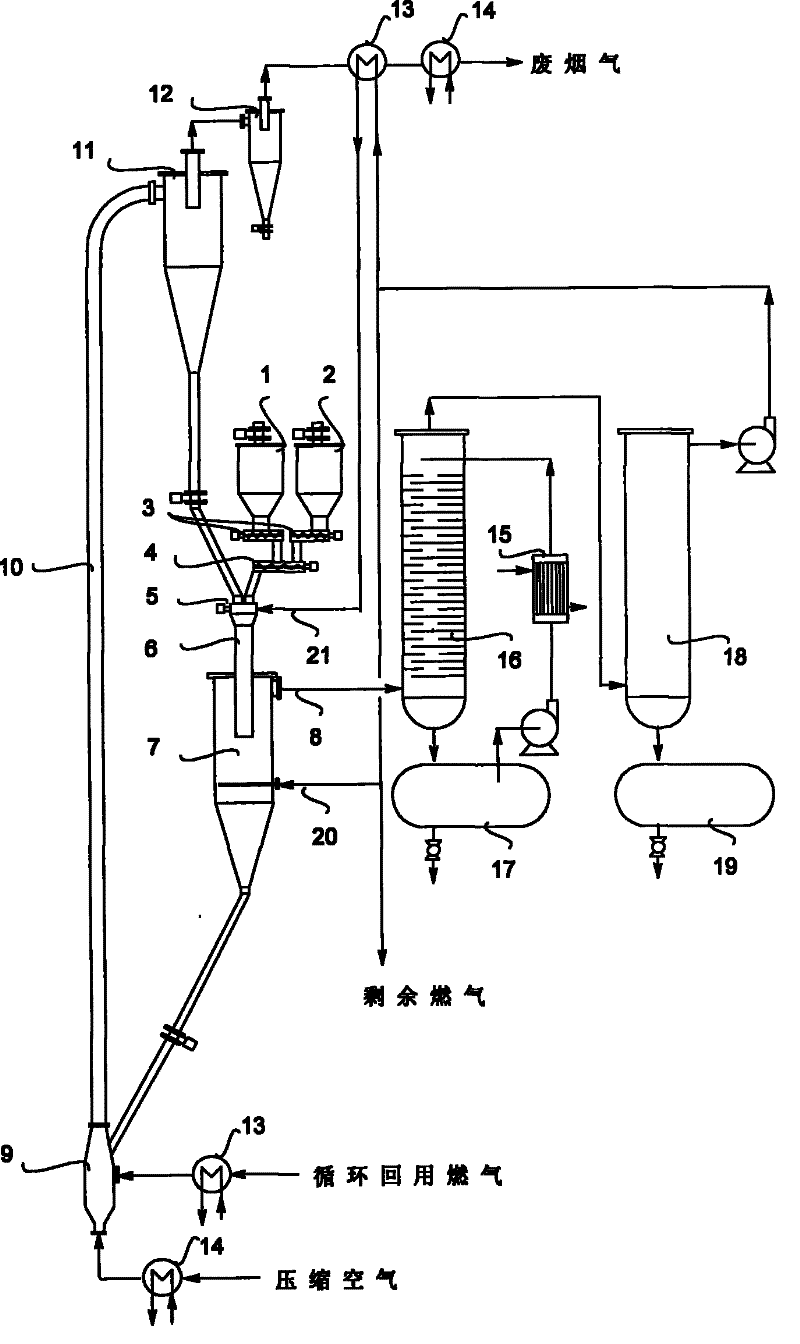

[0034] The implementation of one of the preferred solutions of the present technology will be further described below in conjunction with the accompanying drawings.

[0035] The raw material biomass is dried until the moisture is less than 10%, and the particle size is less than 3mm in terms of the minimum diameter, and the raw material coal moisture is less than 6%, and the particle size is less than 3mm. The mass ratio of biomass and coal is 90 / 10-75 / 25. Biomass and coal are fed into the mixing section 5 of the pyrolysis reactor from the biomass raw material storage tank 1 and the coal raw material storage tank 2 via the primary screw feeder 3 and the secondary screw feeder 4 respectively, and are recycled from the heat carrier tank 11 The solid heat carrier is quickly mixed and enters the co-current pyrolysis section 6 of the pyrolysis reactor. At the same time, the biomass and coal are heated to the pyrolysis reaction temperature of 450°C to 650°C within less than 2s. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com