Allicin fatty milk injection and preparation technics thereof

A technology of allicin and fat emulsion, which is applied in the direction of emulsion delivery, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of unbearable pain, toxic side effects, stinging of blood vessel walls, etc., and achieve the purpose of covering up defects Odor, reduce toxic and side effects, reduce irritation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

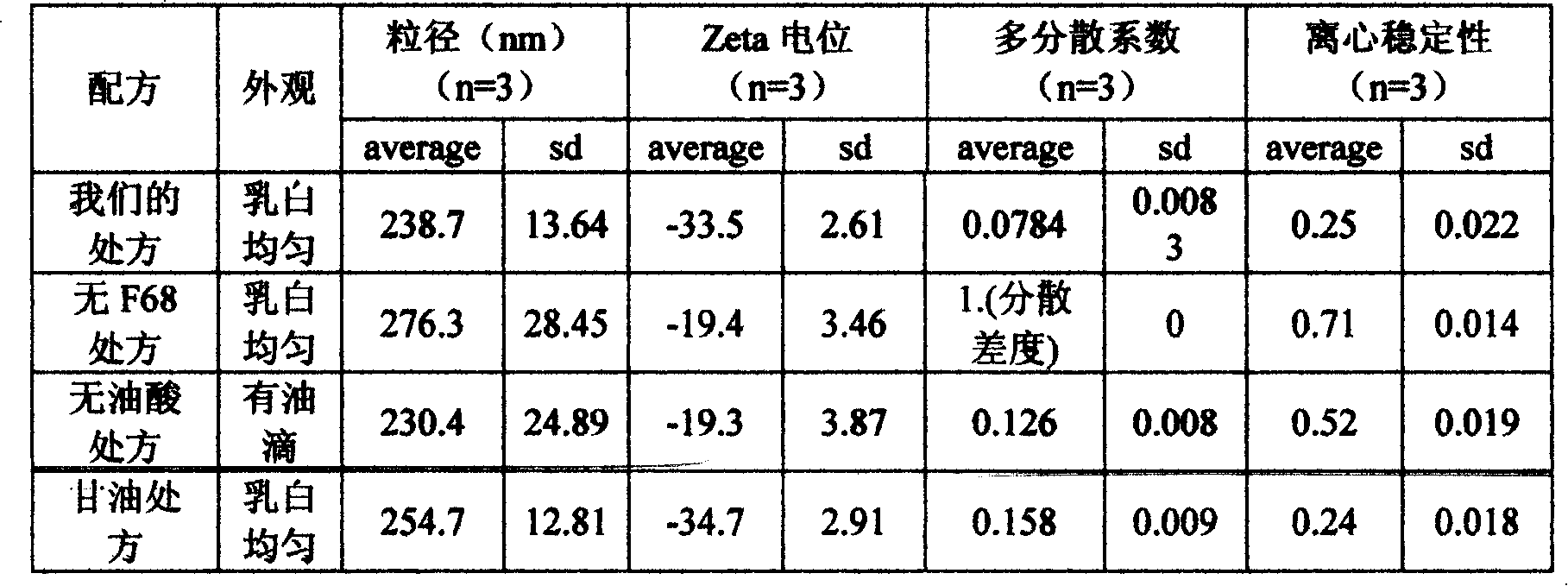

[0029] Take 2 grams of egg yolk lecithin, 0.50 grams of oleic acid, 0.5 grams of vitamin E, and 10 grams of soybean oil in the prescribed amount, mix, heat to 70 ° C, and stir to dissolve. Then add 100 mg of allicin and stir until dissolved. After 0.22 μm PTFE microporous filter membrane was pressurized at 5 MPa to obtain the filtrate; take 1 gram of glycerin in the prescribed amount, add 90 grams of water for injection at room temperature, add 50 mg of disodium edetate and 0.5 gram of Pluronic F68, mix, and stir until dissolved, filtered through a 0.22 μm polytetrafluoroethylene microporous filter membrane and pressurized at 5 MPa to obtain the filtrate; the two filtrates were mixed at room temperature, stirred by a high-speed mixer at a speed of 8000 rpm, and the pressure of the high-pressure homogenizer was controlled at 50000 psi, and the pH of the mixed solution was 7.2. It is the allicin fat emulsion product. The particle size of the oil phase of the product ranges from 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com