Barium crown sealed glass and preparation and application thereof

A technology for sealing glass and glass, which is applied to lead-free sealing glass and its preparation and application fields, can solve the problems of poor chemical stability and electrical performance, cannot adapt to lead-free, and has no cost advantage, and achieves convenient operation. , the effect of low cost and excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

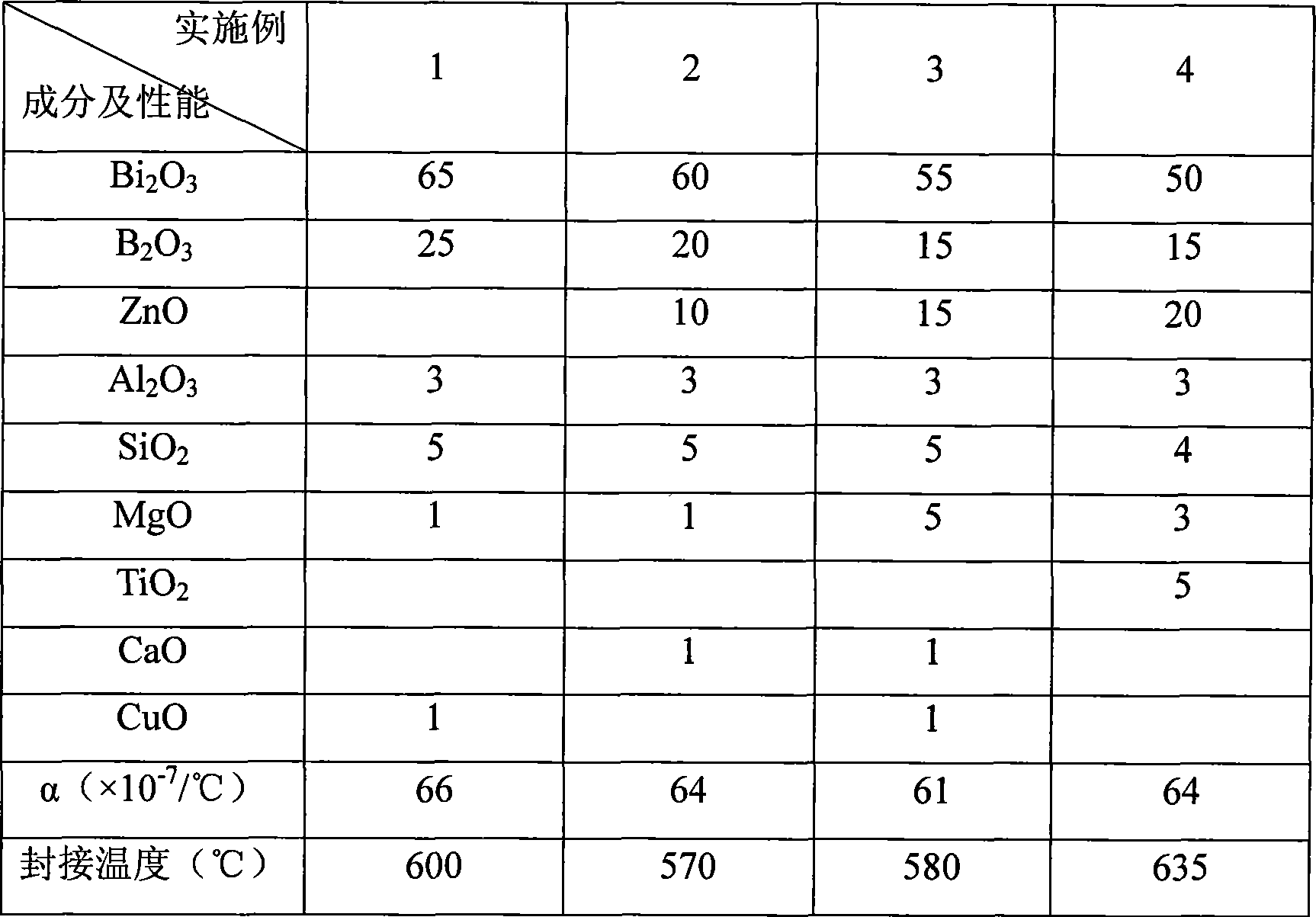

[0030] According to the weight percentage of the composition in Table 1, the ingredients are mixed evenly, the glass frit is put into a quartz crucible, and heated and melted in a silicon carbide rod electric furnace at a melting temperature of 1270°C and kept for 11 minutes.

[0031] The annealed sample is ground into a cylindrical sample of φ5×25mm for performance analysis: the coefficient of thermal expansion (α) is measured by a WRP-1 microcomputer thermal dilatometer, and the temperature rises from room temperature to 300°C with a heating rate of 5°C / min; The sealing temperature is obtained through a hemispherical experiment, and the test results are shown in Table 1.

[0032] The melted glass is poured into a tablet press to be pressed into tablets, and then it is ball-milled into powdered glass powder, and the sieved glass powder is packaged for use by users.

Embodiment 2

[0034] According to the weight percentage of the composition in Table 1 and mix evenly, put the glass frit into a quartz crucible, heat and melt in a silicon carbide rod electric furnace, the melting temperature is 1250°C, and keep warm...

[0035] The annealed sample was ground into a cylindrical sample with a size of φ5×25mm for performance analysis. The test results are shown in Table 1.

[0036] The melted glass is poured into a tablet press to be pressed into tablets, and then it is ball-milled into powdered glass powder, and the sieved glass powder is packaged for use by users.

Embodiment 3

[0038] According to the weight percentage of the composition in Table 1, the ingredients are mixed evenly, the glass frit is put into a quartz crucible, and heated and melted in a silicon carbide rod electric furnace at a melting temperature of 1230°C.

[0039] The annealed sample was ground into a cylindrical sample with a size of φ5×25mm for performance analysis. The test results are shown in Table 1.

[0040] The melted glass is poured into a tablet press to be pressed into tablets, and then it is ball-milled into powdered glass powder, and the sieved glass powder is packaged for use by users.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com