Capillary discharging X-laser device using blumlein line and eliminating prepulse

A laser device and pre-pulse technology, which is applied to lasers, laser components, circuits, etc., can solve the problems of inability to quickly separate the plasma from the tube wall, uneven breakdown channels, tube wall ablation, etc., and reach the tube wall The effect of reduced ablation amount, reduced background radiation, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

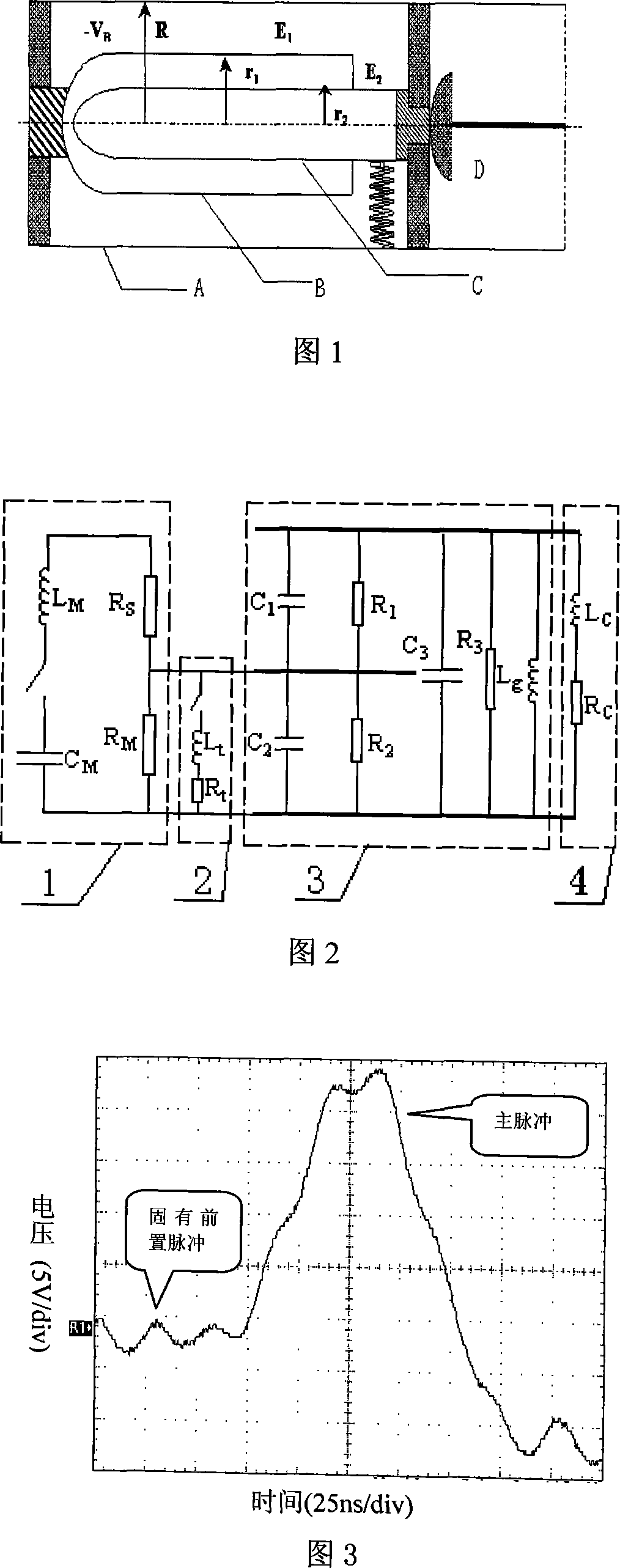

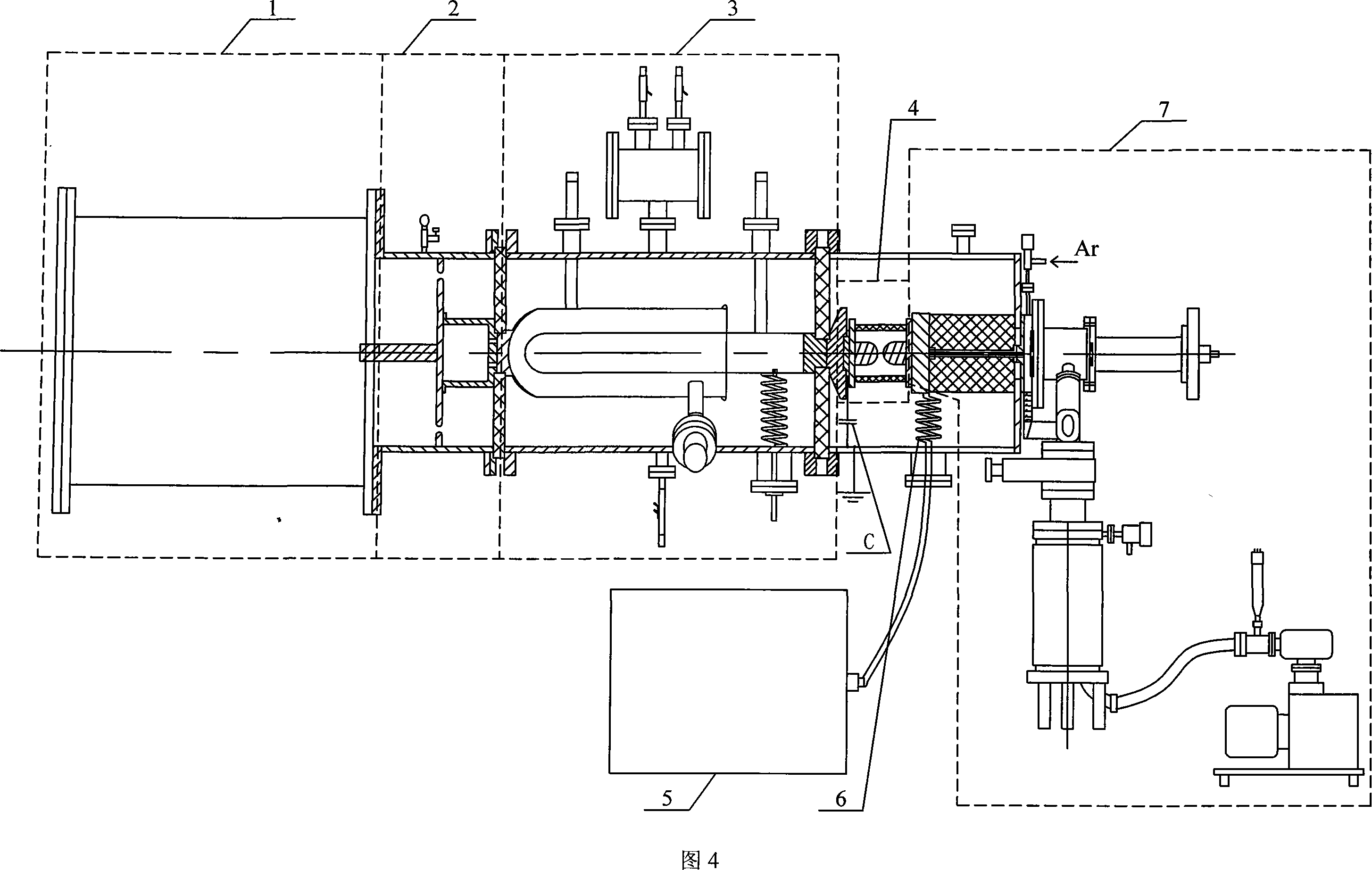

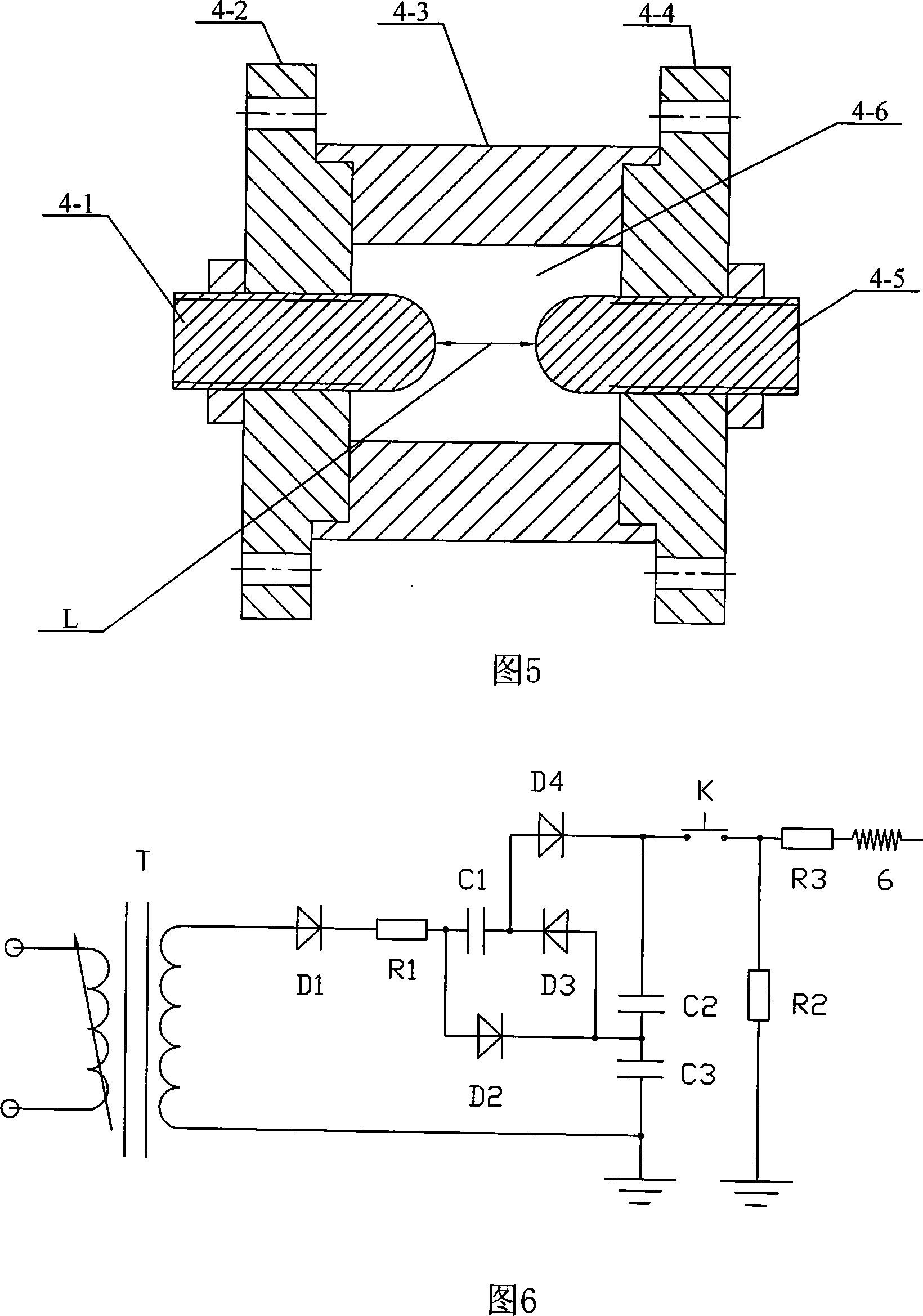

[0009] Specific embodiment 1: This embodiment is described with reference to Fig. 4, Fig. 5, and Fig. 6. This embodiment consists of a fast high-voltage electric pulse Marx generator 1, a main switch 2, a Blumlein transmission line 3, and an inherent pre-pulse isolation switch 4, Pre-pulse generator 5, isolation inductor 6, capillary tube and X-ray test assembly 7;

[0010] The electrical pulse output end of the fast high-voltage electrical pulse Marx generator 1 is connected to the input end of the main switch 2, the output end of the main switch 2 is connected to the input end of the Blumlein transmission line 3, and the output end of the Blumlein transmission line 3 is connected to the inherent pre-pulse isolation switch 4 The input end of the inherent pre-pulse isolation switch 4 and one end of the isolation inductor 6 are connected to the capillary and the electrical pulse input end (cathode) of the X-ray test assembly 7, and the other end of the isolation inductor 6 is conne...

specific Embodiment approach 2

[0016] Specific embodiment 2: This embodiment will be described with reference to FIG. 4. This embodiment adds a capacitor C based on the specific embodiment 1. One end of the capacitor C is connected to the input terminal of the inherent pulse isolation switch 4, and the other end of the capacitor C is connected to the ground . The capacitance value of the capacitor C is 100pf~900pf.

[0017] This embodiment has the best isolation effect on the inherent pre-pulse, and can completely guarantee the stable operation of the capillary discharge device, and at the same time obtain a good main pulse current waveform, so that the amplitude of the laser spike is further improved.

[0018] Working principle: When the system is working, the pre-pulse generator 5 adds the pre-pulse to the cathode of the capillary tube and the X-ray test assembly 7 through the isolation inductor 6, and at the same time, it can trigger the fast high-voltage electric pulse Marx generator 1 through a delay circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com