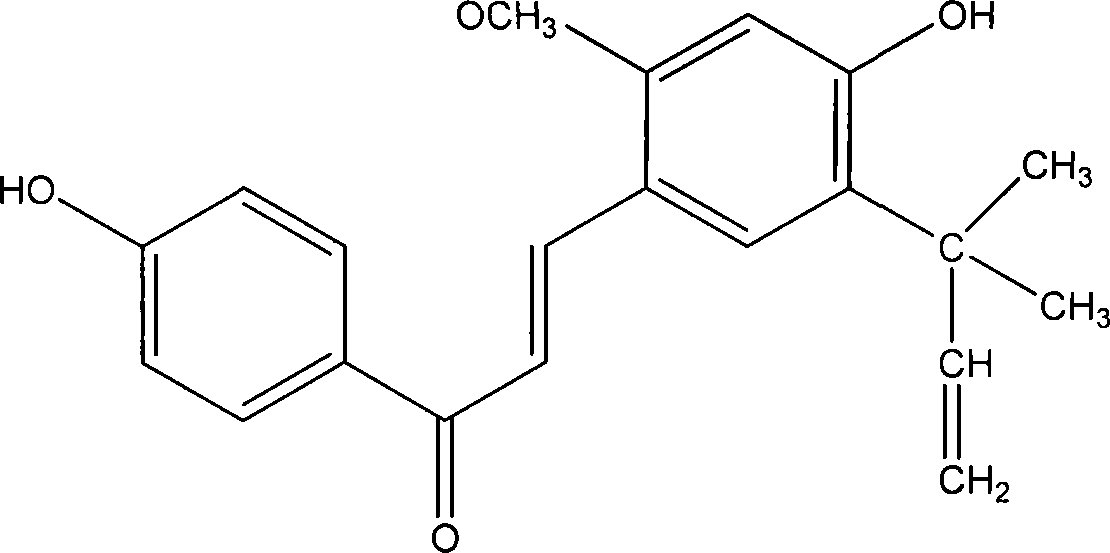

Method for preparing high-purity liquorice chalcone A

A licorice chalcone, high-purity technology, applied in the field of medical drugs and chemical industry, can solve the problems of high cost and complicated operation, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

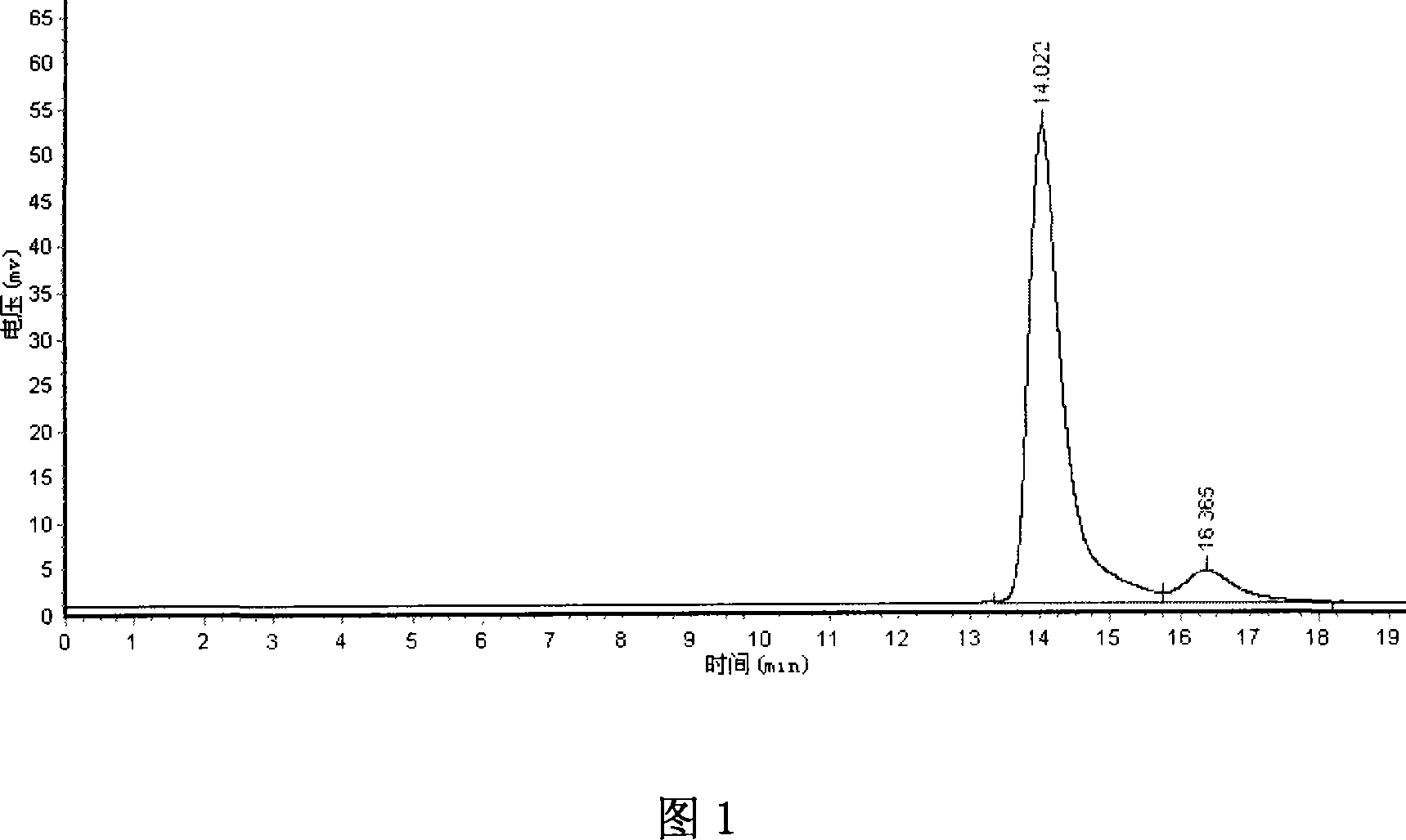

Embodiment 1

[0022] Weigh 1Kg of dried and pulverized licorice powder, soak it with 20 times the amount of 80% ethanol at room temperature for 2 hours, then extract by cold infiltration method, the percolation speed is 10mL / min, the percolation liquid is concentrated under reduced pressure, and concentrated to a specific gravity of 1.08 (20°C), stir and extract 3 times with water-saturated n-butanol at a ratio of 1:1, combine the extracts and concentrate under reduced pressure to recover n-butanol, the obtained concentrate is adsorbed with 500 g of macroporous D101 resin, and eluted with a gradient of ethanol and water. , wherein the proportion of water in ethanol water is from 100wt%, the interval is 20wt%, the gradient decreases to 0wt%, the effluent is checked by thin-layer chromatography detection method, the effluent containing licorice A is collected, and the licorice is concentrated under reduced pressure. The concentrate of licorone A was crystallized with isopropyl ether-acetone to...

Embodiment 2

[0024] Weigh 1Kg of dried and pulverized licorice powder, extract 2 times by mass ratio of 1:3 and 1:2 with absolute ethanol, each time for 1 hour, filter, merge the filtrate, recover ethanol under reduced pressure, add water to the specific gravity after concentration 1.10 (20°C), stir and extract 3 times with ethyl acetate at a ratio of 1:1, combine the extracts, recover ethyl acetate under reduced pressure, the obtained concentrate is adsorbed with 500 g of polyamide, and eluted with a gradient of ethanol and water, wherein water accounts for ethanol. The proportion of water is from 100wt%, the interval is 15wt%, and the gradient decreases to 0wt%. The effluent is checked by thin-layer chromatography detection method, and the effluent containing licochalone A is collected, and concentrated under reduced pressure to obtain licochalone A concentrate , and then crystallized from ethanol-isopropyl ether to obtain 2.07 g of pure licorice chalcone A with a purity of 91.82%.

Embodiment 3

[0026] Weigh 1Kg of dried and pulverized licorice powder, extract 3 times with 10 times, 5 times, and 5 times of 80% acetone water respectively. The first extraction is 3 hours, the second extraction is 1 hour, and the third extraction is 1 hour. The extract was recovered under reduced pressure at 40°C with acetone, concentrated to a specific gravity of 1.05 (20°C), continuously extracted with ethyl acetate at a ratio of 1:3, and the extract was concentrated. Elution, wherein the proportion of water in ethanol water is from 100wt%, the interval is 20wt%, the gradient is decreased to 0wt%, the effluent is checked by thin-layer chromatography detection method, the effluent containing licochalone A is collected, and concentrated under reduced pressure to obtain The licorice chalcone A concentrate was crystallized through isopropyl ether-acetone to obtain 2.73 g of licorice chalcone A pure product with a purity of 91.77%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com