Process for synthesizing azo dispersion dyes monomer compound

A technology of disperse dyes and synthesis process, which is applied in the direction of azo dyes, monoazo dyes, organic dyes, etc. It can solve the problems of increasing costs, waste of industrial resources, affecting the yield and quality of dyes, and achieves the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

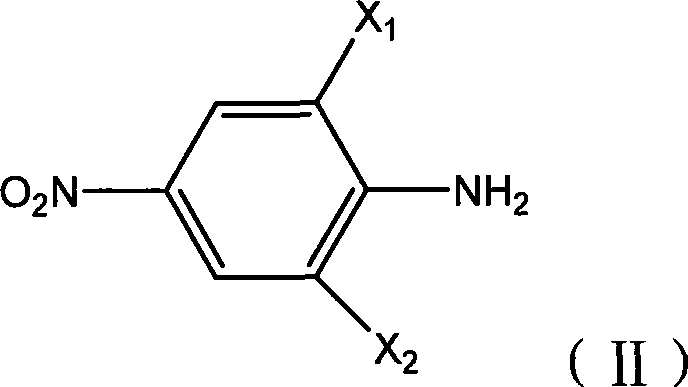

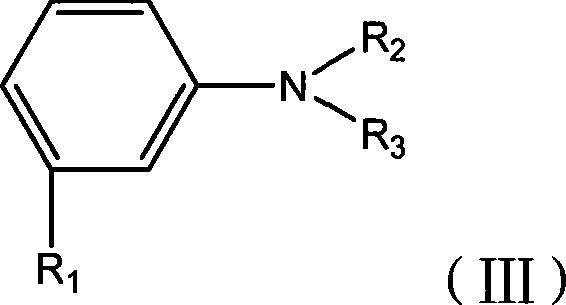

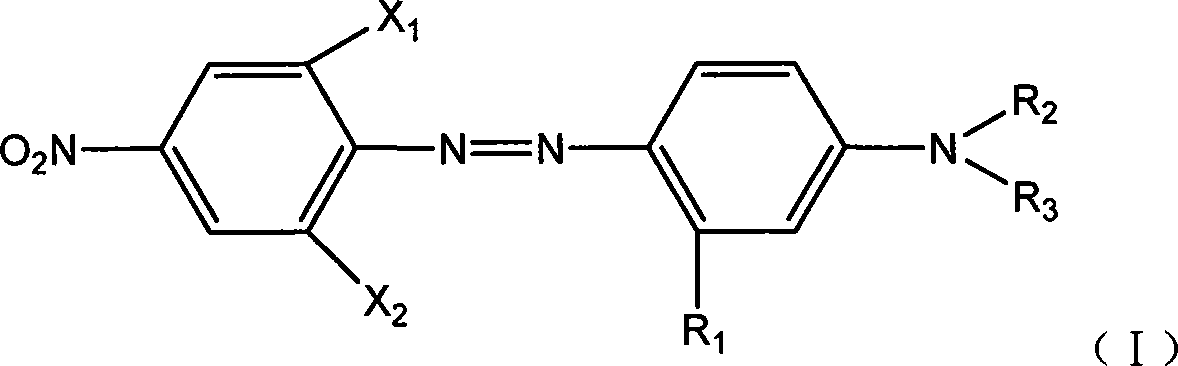

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 100g of 98% sulfuric acid and 65.4g of 40% nitrosylsulfuric acid (liquid sulfide) were dropped into the three-necked flask successively, and the temperature was lowered with stirring; After adding for 2 hours, after keeping warm for 5-10 hours, use a glass rod to dip a few drops of diazonium solution into ice water. The ice water is clear and the potassium iodide test paper is blue, depending on the end of the reaction, let it stand for later use.

[0022] Put 1000ml of water in a 2000ml beaker, control the temperature of the bottom water at 18-28°C, add 3g of Pingpingjia O-25 and 3g of sulfamic acid, and stir for 1 hour to completely dissolve the Pingpingjia O-25; control the temperature of the bottom water At 18-28°C, quickly put 46.4g of yellow palm esterification solution (N-cyanoethyl-N-acetoxyethylaniline) in a reduced amount, and then beat for about 30 minutes under the condition of 18-28°C; After coupling and beating, slowly add the diazo dilution solution into ...

Embodiment 2

[0025] Put 100g of 98% sulfuric acid and 65.4g of 40% nitrosylsulfuric acid into the three-necked flask successively, stir and cool down; slowly put in 41.4g of 2,6-dichloro-p-nitroaniline at 20-30°C, and finish adding in about 2 hours , after 5-10 hours of heat preservation, check the clarity and the end point; when the end point is reached, let it stand for later use.

[0026] Add 1000ml of bottom water to a 2000ml beaker, add 3g of Pingpingjia and 34.8g of N-ethyl-N-cyanoethylaniline, beat for about 2 hours below 15°C, add sulfamic acid, drop the temperature below 20°C and add diazonium solution , about 30 minutes or so added, the temperature of the diazo addition process need not be controlled. After reacting for 10 hours, detect the end point, filter and wash with water until neutral. The dye monomer of formula (I-2) can be prepared.

[0027]

Embodiment 3

[0029] Put 100g of 98% sulfuric acid and 65.4g of 40% nitrosylsulfuric acid into the three-necked flask successively, stir and cool down; slowly put in 59.2g of 2,6-dibromo-p-nitroaniline at 20-30°C, and finish adding in about 2 hours , after 5-10 hours of heat preservation, check the clarity and the end point; when the end point is reached, let it stand for later use.

[0030] Add 1000ml of bottom water to a 2000ml beaker, add 3g of Pingpingjia and 34.8g of N-ethyl-N-cyanoethylaniline, beat for about 2 hours below 15°C, add sulfamic acid, drop the temperature below 20°C and add diazonium solution , about 30 minutes or so added, the temperature of the diazo addition process need not be controlled. After reacting for 10 hours, detect the end point, filter and wash with water until neutral. The dye monomer of formula (I-3) can be obtained.

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com