High-concentration composite reactive dye

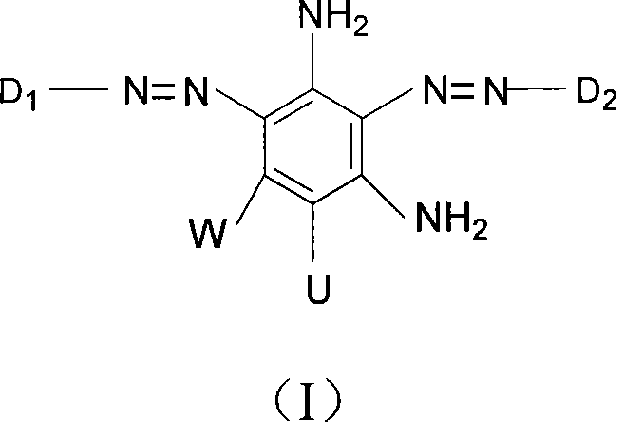

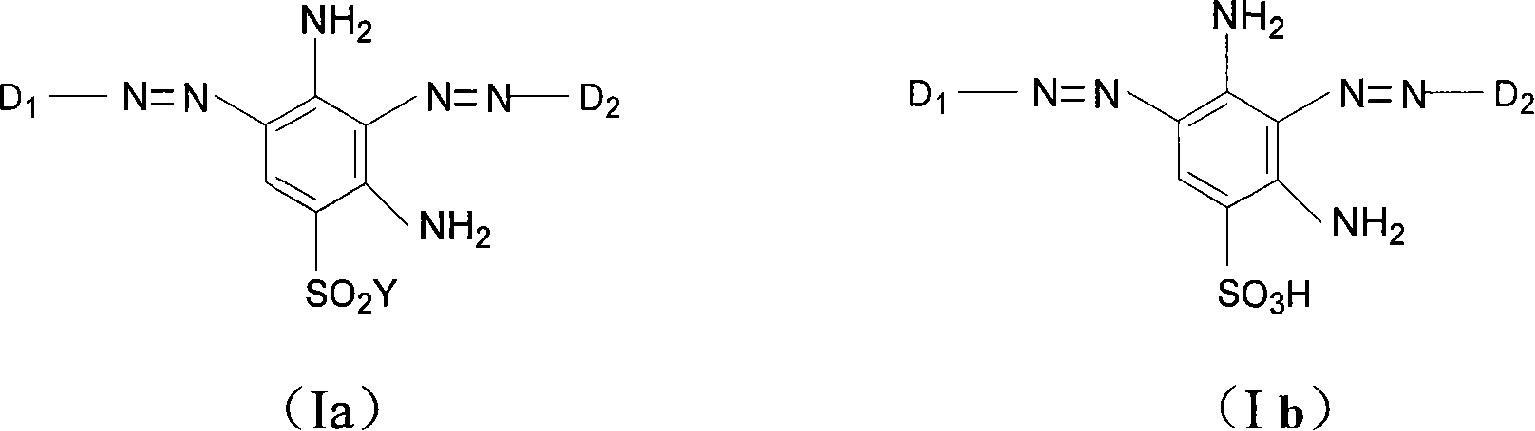

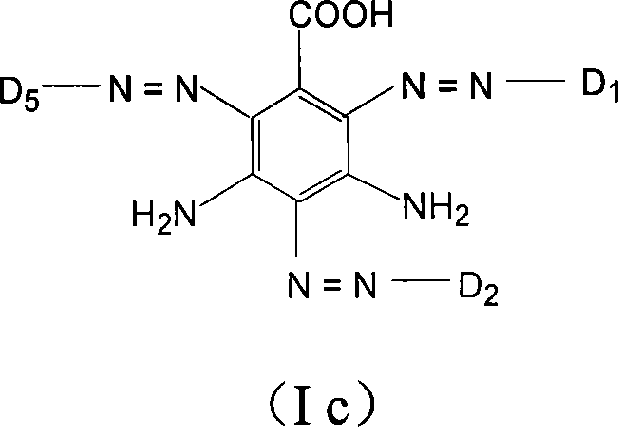

A reactive dye and high-concentration technology, applied in the field of black or brown composite dyes, can solve the problem of low color fixation rate of black reactive dyes, and achieve excellent dyeing performance, high color fixation rate, level dyeing and good lifting power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Mix 36.2 parts of 4-(β-hydroxyethylsulfone sulfate)-aniline with 350 parts of water and beat for ~60min, add 46 parts of 30% sodium nitrite solution dropwise from the liquid surface at 0~5°C, at this temperature Stir until the diazotization reaches the end point.

[0038] Add the aqueous solution containing 29.6 parts of compound (3) to the above-mentioned diazonium salt, perform a coupling at ~5°C, and keep the pH at 4~5°C; Maintain at 8-10°C. When the reaction reaches the end point, raise the temperature to 40°C, add 5 parts of activated carbon, stir for 12-20 minutes, filter, and directly spray-dry the dye solution to obtain the dye (101) with the following structural formula:

[0039]

[0040] Dye dyed cotton fiber is yellow, and the fastness is good.

Embodiment 2~15

[0042] The yellow-orange dye listed in Table 1 can be obtained with reference to the method of Example 1.

[0043] Table 1

[0044]

[0045]

[0046]

[0047]

Embodiment 16

[0049] Mix 32 parts of 3-amino-N-[4-(β-hydroxyethylsulfone sulfate)-phenyl]benzamide with 350 parts of water for beating for ~60 minutes, and slowly add 30% of 46 parts of sodium nitrite solution, stirred at this temperature until the diazotization reached the end.

[0050] Add an aqueous solution containing 18.8 parts of 2,4-diaminobenzenesulfonic acid to the above-mentioned diazonium salt, perform a coupling at ~5°C, and keep the pH at 3 to 4; after the reaction is completed, add 28.1 parts of 4-(β -Hydroxyethyl sulfone sulfate)-diazonium salt prepared from aniline for secondary coupling, adjust the pH to 6-6.5 with sodium bicarbonate, and maintain the temperature at 8-10°C. When the reaction reaches the end point, raise the temperature to 40°C, add 5 parts of activated carbon, stir for 12-20 minutes, filter, and directly spray-dry the dye solution to obtain the dye (201) with the following structural formula:

[0051]

[0052] Dye dyed cellulose fiber is brownish yellow, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com