Process for producing sterile water containing hypochlorous acid or chlorous acid as its main component and apparatus therefor

A sterilizing water and chlorous acid technology, applied in the direction of sterilization/microdynamic water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problem of maintaining a certain amount of non-sterilizable water, pH and concentration maintenance wait for the question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

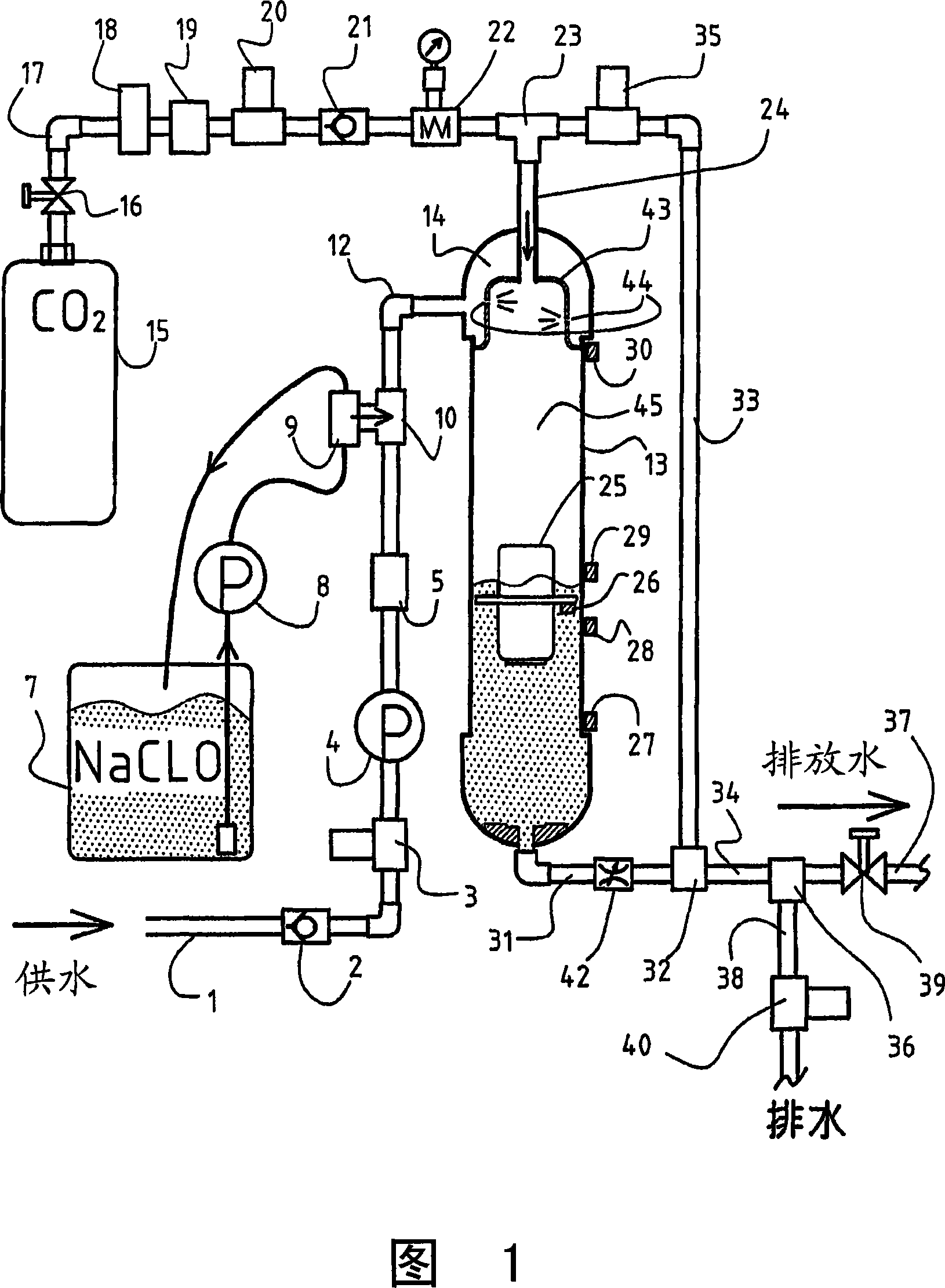

[0043] The first embodiment (Fig. 1, Fig. 2):

[0044] Fig. 1 shows a sterilizing water generating device of the first embodiment, and Fig. 2 is a schematic diagram of the structure of the device. Reference numeral 1 is a raw water supply pipe, such as tap water, well water, and sea water as raw water, and a check valve 2 , an electric switch valve 3 , a pump 4 , and a flow meter 5 are installed in the raw water supply pipe 1 . In addition, when using raw water that is pressure-fed, such as tap water, the pump 4 for pressure-feeding the raw water can also be omitted. Reference symbol 7 is a raw material tank for storing sodium hypochlorite aqueous solution, and 8 is a pump. The sodium hypochlorite aqueous solution in the raw material tank 7 is sent to the adding part 10 through the flow path switching valve 9 to be mixed with raw water. An aqueous solution of sodium hypochlorite diluted to a desired concentration by mixing with raw water is supplied to an upper space 14 of ...

no. 2 Embodiment

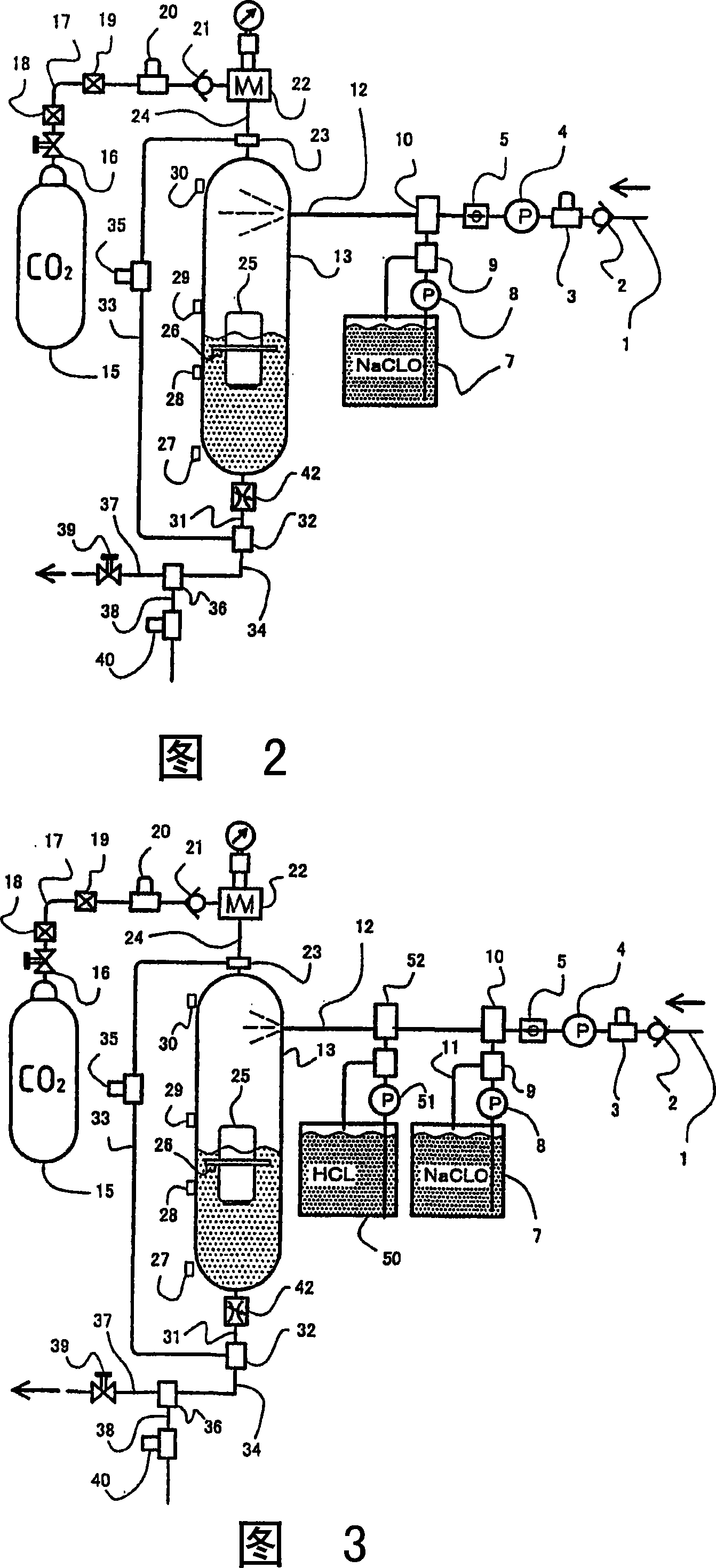

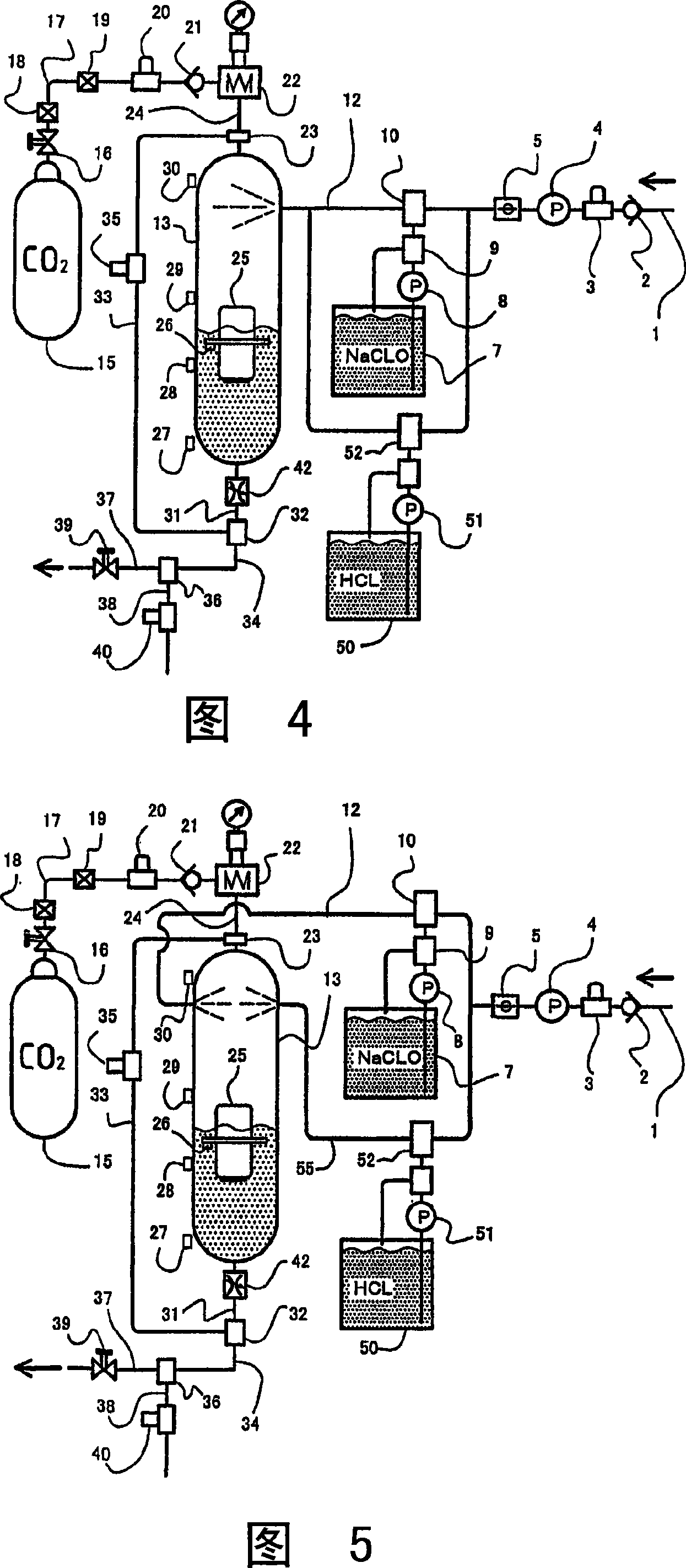

[0072] The second embodiment (Fig. 3)

[0073] The second embodiment shows an example of mixing an inorganic acid such as hydrochloric acid or sulfuric acid or an organic acid such as acetic acid or lactic acid (typically hydrochloric acid diluted with water) other than carbonic acid. Specifically, prepare the additional raw material tank 50 that acid such as dilute hydrochloric acid is housed, use the pump 51 of this addition to send the acid of this added raw material tank 50 into the raw material supply pipe 12 or the raw water supply pipe 1 in the addition part 52 sodium hypochlorite aqueous solution By mixing, the pH adjustment before supplying the sodium hypochlorite aqueous solution to the pressure vessel 13 is performed in this way.

[0074] Utilize the stage before the final pH adjustment of carbon dioxide gas in the pressure vessel 13 to carry out this pH adjustment. It can be to adjust the pH of the sodium hypochlorite aqueous solution to, for example, slightly al...

no. 3 Embodiment

[0077] The 3rd embodiment (Fig. 4):

[0078] The third embodiment is a modified example of the second embodiment described above. In the above-mentioned 2nd embodiment, the addition part 10 that adds sodium hypochlorite aqueous solution is arranged in series with the additional addition part 52 that adds acid, but also can be shown in this 3rd embodiment, add part 10 and the addition part 52 of addition Parallel configuration (Figure 4). That is, an aqueous sodium hypochlorite solution and dilute hydrochloric acid may be added to raw water, and then mixed to perform auxiliary adjustment of the pH of the aqueous sodium hypochlorite solution, and the aqueous sodium hypochlorite solution after the auxiliary pH adjustment may be supplied to the pressure vessel 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com