Ti Hz quanta cascaded semiconductor laser material and its growth method

A technology of quantum cascade, growth method, applied in the field of semiconductor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

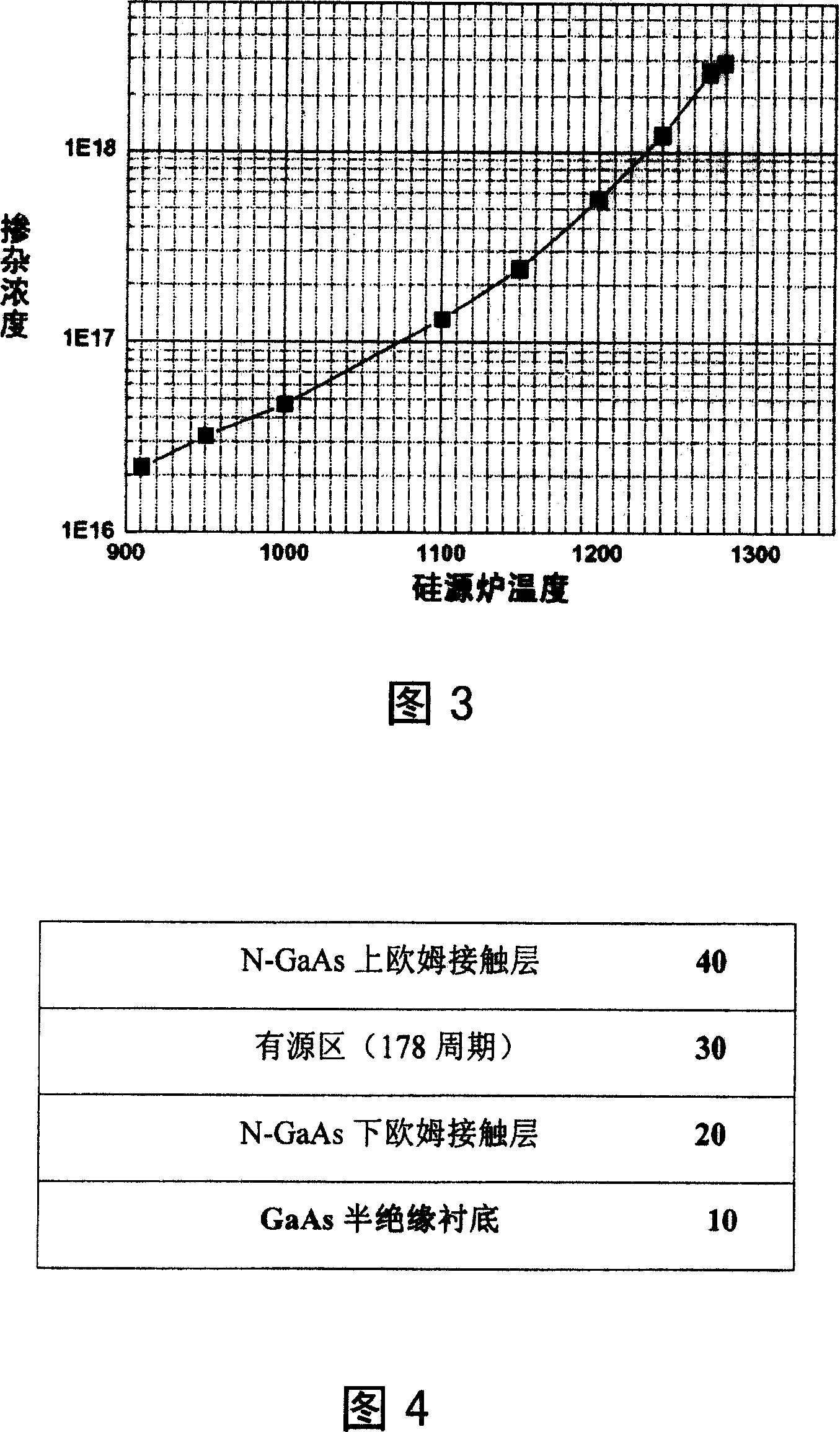

[0038] Please refer to Fig. 4, a method for growing a terahertz quantum cascade semiconductor laser material according to the present invention includes the following growth steps:

[0039] Step 1: take half of the insulating gallium arsenide substrate 10; before growing each layer on the semi-insulating gallium arsenide substrate 10, the aluminum and gallium beam current values under the set growth rate and material composition should be determined, The method is to measure the thickness of the AlGaAs epitaxial layer that meets the design composition, and obtain the corresponding growth rate of AlGaAs under the aluminum and gallium beams after dividing the epitaxial layer, and then obtain the growth rate of GaAs according to the proportional relationship, and then obtain Corresponding beam current value;

[0040] Step 2: using molecular beam epitaxy to grow an N-type gallium arsenide lower ohmic contact layer 20 on the semi-insulating gallium arsenide substrate 10 to make a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com