Method and device for producing biological siliceous material with reactor culture sponge or its cell

A reactor, bio-silicon technology, applied in biochemical equipment and methods, microorganisms, tissue culture, etc., can solve problems such as waste of resources, and achieve the effect of easy collection and low substrate concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

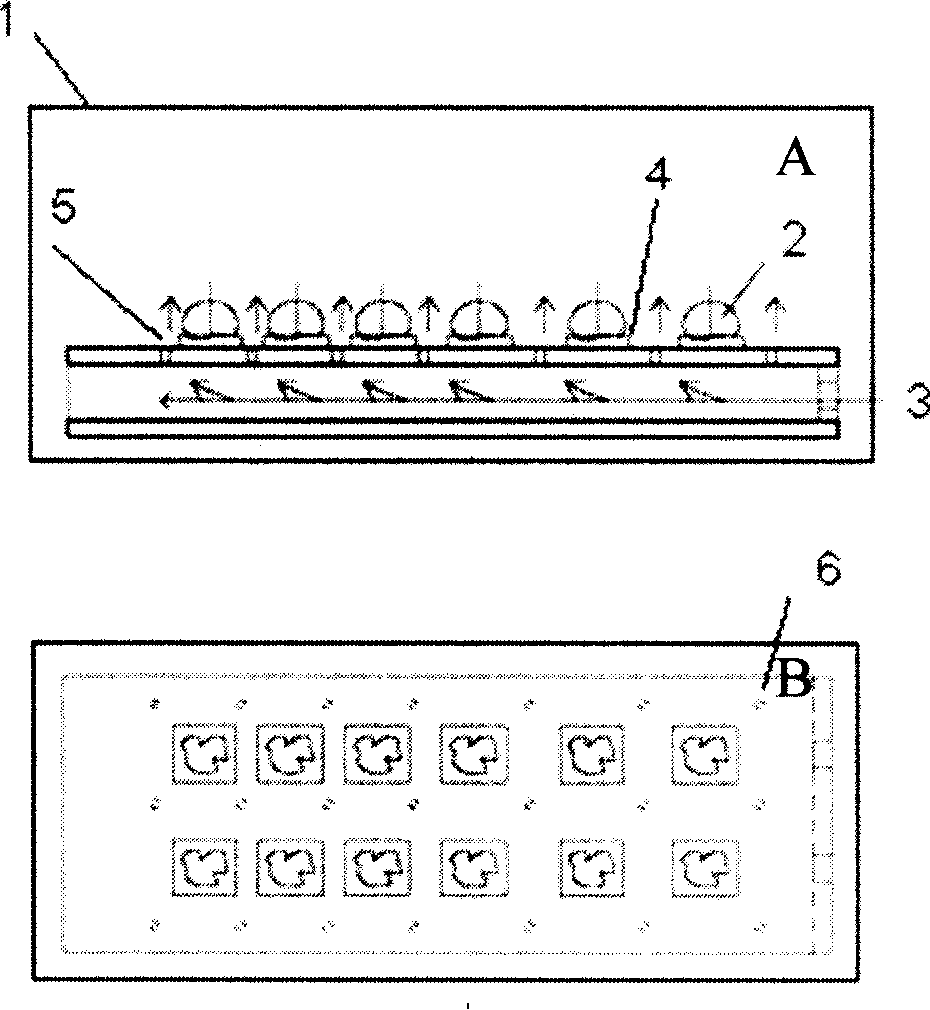

Method used

Image

Examples

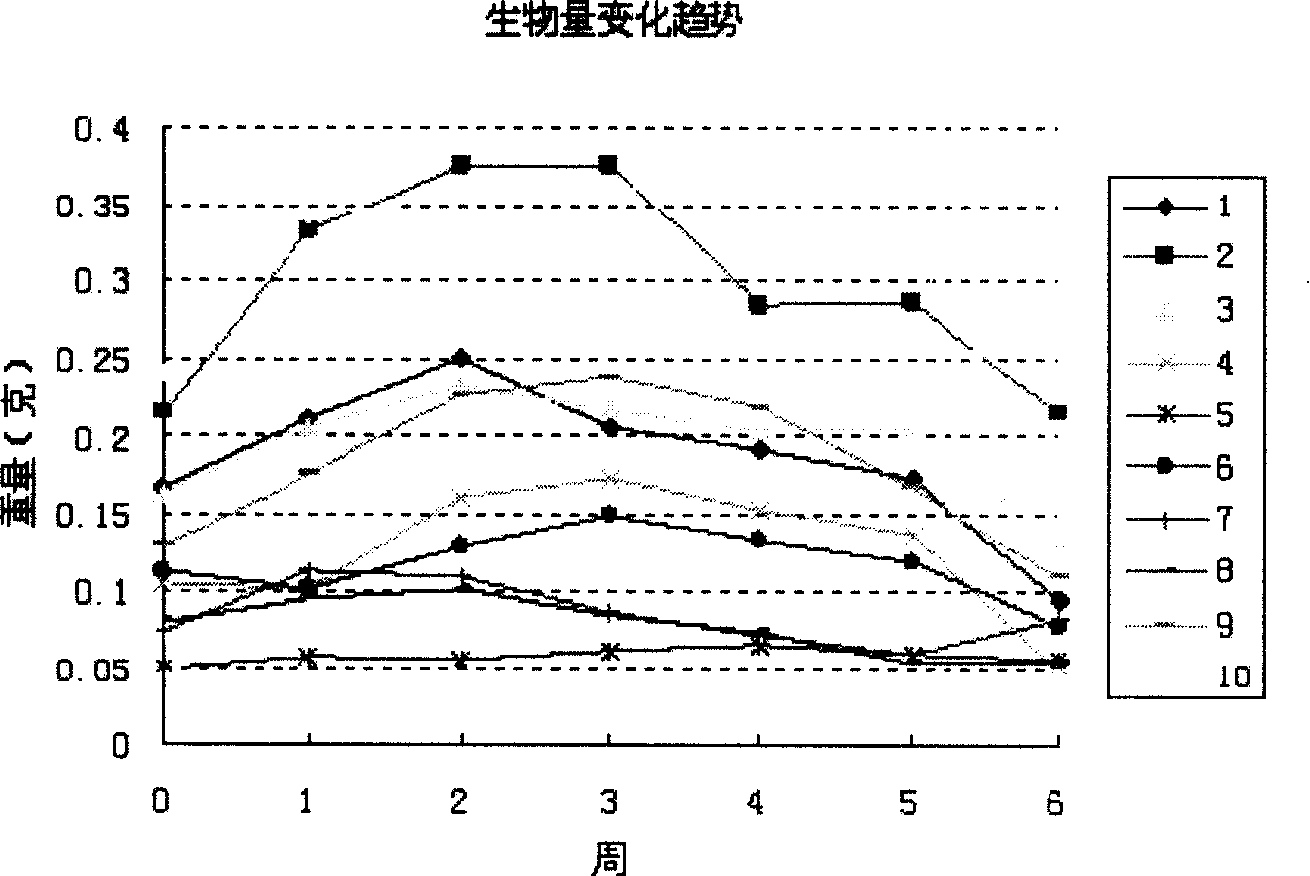

Embodiment 1

[0045] Wash the freshly collected luxuriant membrane sponge with 200mL of natural seawater filtered through a 0.22μM filter membrane to remove algae and sediment attached to the surface, and store it in the laboratory for three days; cut the sponge with a scalpel into 0.5×0.5 cm 2 Small pieces, ten pieces in total, about 1 gram, transferred into 200mL natural seawater which was sterilized by 0.22μm membrane filter and added with 400mg / L gentamycin, and allowed to stand for 10 minutes; in a liquid-liter plug-in reactor Add 1.8L of natural seawater filtered and sterilized by a 0.22μm filter membrane; insert the treated sponge block on the glass base of the liquid lift plug-in reactor, and cultivate in the culture reactor; the final concentration of adding 200,000 per week The golden algae of cell / mL is used as food; the sponge is taken out together with the plug every week, the surface dirt is removed and the surface seawater is dried, and weighed. The sponge tissue showed an i...

Embodiment 2

[0047] Take the temporary laboratory sponge and cut it into 0.5×0.5cm with a scalpel 2 Small pieces, ten pieces in total, 1.3g, transferred into 200mL natural seawater which was sterilized by filtration and added with 400mg / L gentamycin, and allowed to stand for 10 minutes; The natural seawater sterilized by μm filter membrane; the treated sponge block was inserted on the glass base of the liquid-lift plug reactor, and cultivated in the culture reactor; gold with a final concentration of 200,000 cells / mL was added every week Algae were used as food, and 60 μm silane coupling agent 3-ureidopropyltrimethoxysilane was added at the same time; the bones discarded by the sponge were collected when weighing every week, and dried; after the sixth week, the sponge tissue was collected and weighed. Weighing about 1.2g; all the spongy tissue and bone residues were treated with 20mL of mixed acid of concentrated sulfuric acid: concentrated nitric acid=3:1 (volume ratio) at 80°C for one ho...

Embodiment 3

[0049] After the sponge was collected, it was treated with 7ppm CuSO4 and 400mg / L GentamycinSulfate (Justaware Pharmaceutical Co.Ltd) for three hours after 24 hours of temporary cultivation. Refer to the literature (Primmorphs from archaeocytes-dominant cell population of the sponge Hymeniacidon perleve: Improved cell proliferation and spiculogenesis (Biotechnology and Bioengineering, v84-5, 583-590)) to perform Ficoll cell density gradient separation, and take 12-15% of the cells for ADCP culture. Cell culture was carried out in 9 cm Petri dishes (Corning) at a seeding density of 5 × 10 6 cell / mL. The culture medium is natural seawater filtered through 0.22 μm, and 60 μM silane coupling agent 3-ureidopropyltrimethoxysilane and 30 μM ferric citrate are added. Incubate at 18°C in the dark, and replace 100% of the medium every two days. The presence of new spicules can be found in the cell aggregates after culture, see Figure 5 . Arrows indicate new spicules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com