Method for preparing tert-butanol by isobutene hydration

A technology of isobutene hydration and tert-butanol, applied in the direction of hydroxyl addition preparation, chemical instruments and methods, organic compound/hydride/coordination complex catalyst, etc., can solve the difficulty of reactant separation, increase side reactions, and reaction temperature Advanced problems, to achieve the effect of reducing equipment investment and operating costs, increasing solvency, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

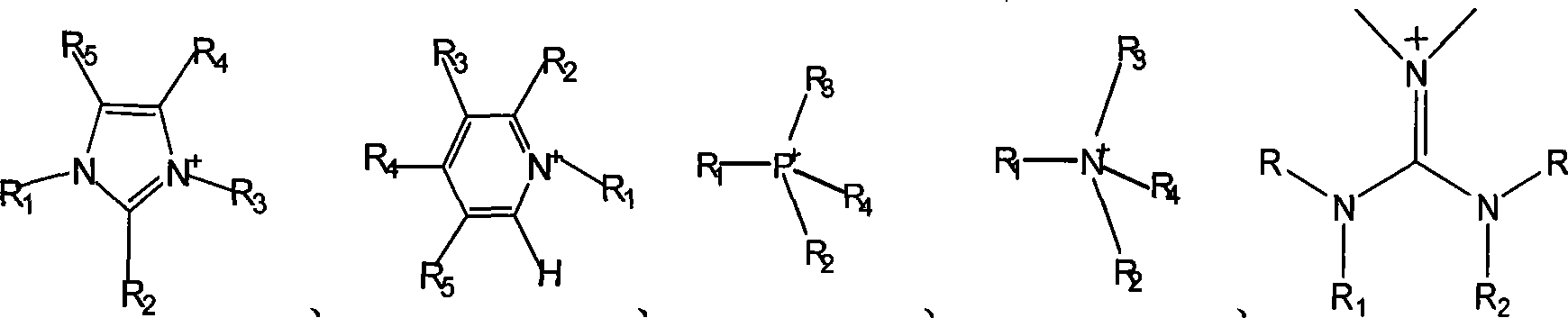

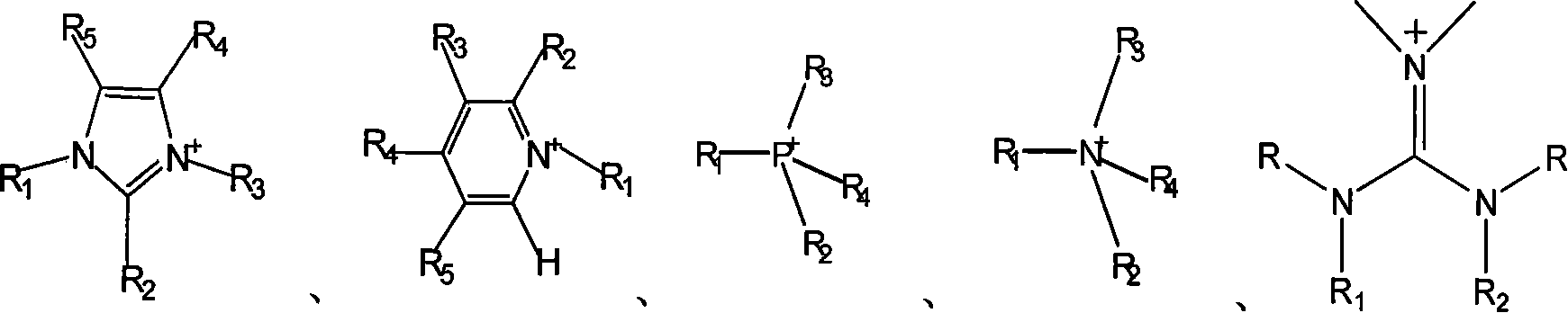

Method used

Image

Examples

Embodiment 1

[0014] At 20°C, add 1.0632g of ionic liquid [Bmim]HSO into a 30ml reactor 4 10ml of aqueous solution, through N 2 After passing the leak test, vacuumize, and then feed isobutene gas to make the pressure reach 0.15MPa, and react for 4 hours at a reaction temperature of 70°C and a rotation speed of 600r / min. The conversion rate of isobutene is 81.5%. The choice of tert-butanol The sex is 99.5%.

Embodiment 2

[0016] With embodiment 1, ionic liquid is changed into [Bmim] H 2 PO 4 , the conversion rate of isobutene was 82.6%, and the selectivity of tert-butanol was 99.3%.

Embodiment 3

[0018] With embodiment 1, ionic liquid is changed into [Bmim] HSO 4 and [Bmim] H 2 PO 4 The mixture, its mass ratio is 1:1, the conversion rate of isobutene is 81.8%, the selectivity of t-butanol is 99.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com