Device and method for preparing metallic titanium by TiCl4 vacuum glow discharge

A technology of glow discharge and metal titanium, which is applied in the field of metal material metallurgy to achieve the effects of high efficiency, simple device structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

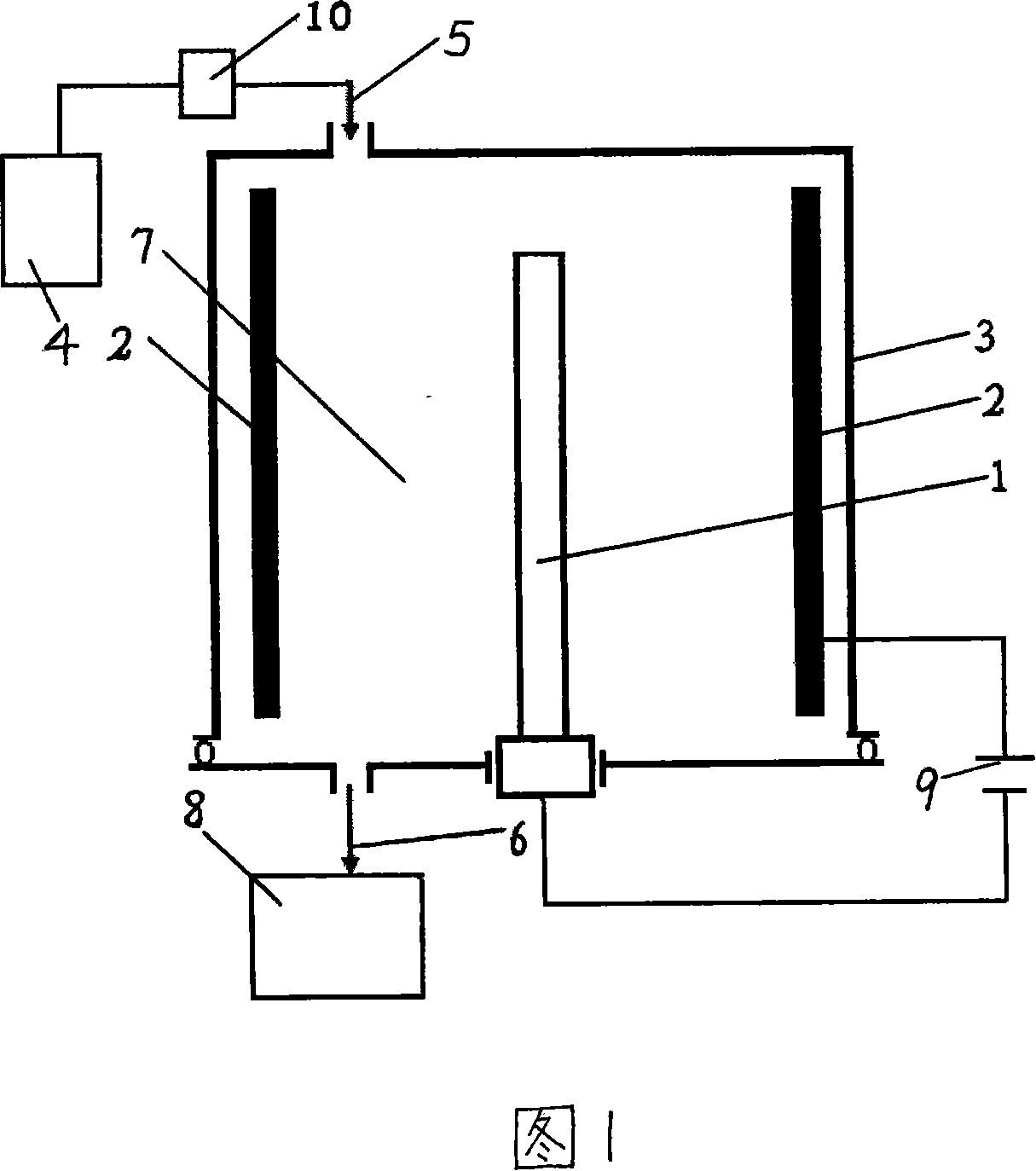

Embodiment 1

[0015] The technical pure TiCl that will be vaporized in the vaporization device 4 4 , pass through the gas flow controller 10 and the vaporization pipeline 5 until the background vacuum reaches 5×10 -3 Pa vacuum chamber 3, controlled TiCl 4 The pressure is 1000Pa, and a negative voltage of 5000V is applied to the collector 1 (cathode) insulated from the vacuum chamber 3 through a DC power supply 9, and the anode 2 insulated from the vacuum chamber 3 generates gas ionization, forming in the region 7 of the two electrodes Glow plasma, under the action of electric field, TiCl 4 The titanium cations in the plasma generated by gas ionization are deposited on the surface of the collector 1 made of sponge-like titanium, and the chlorine gas generated by the discharge is absorbed by the gas collector 8 through the chlorine gas pipeline 6 and stored. After 4 hours of continuous treatment, 10.7Kg of titanium with an oxygen content of less than 0.01% and a chlorine content of less tha...

Embodiment 2

[0017] The technical pure TiCl that will be vaporized in the vaporization device 4 4 , pass through the gas flow controller 10 and the vaporization pipeline 5 until the background vacuum reaches 5×10 -3 Pa vacuum chamber 3, controlled TiCl 4 The pressure is 500Pa, and a negative voltage of 3000V is applied to the collector 1 (cathode) insulated from the vacuum chamber 3 through a DC power supply 9, and the anode 2 insulated from the vacuum chamber 3 generates gas ionization, forming in the region 7 of the two electrodes Glow plasma, under the action of electric field, TiCl 4 The titanium cations in the plasma generated by gas ionization are deposited on the surface of the collector 1 made of sponge-like titanium, and the chlorine gas generated by the discharge is absorbed by the gas collector 8 through the chlorine gas pipeline 6 and stored. After 10 hours of continuous treatment, 5.6 kg of titanium with an oxygen content of less than 0.01% and a chlorine content of less tha...

Embodiment 3

[0019] The technical pure TiCl that will be vaporized in the vaporization device 4 4 , pass through the gas flow controller 10 and the vaporization pipeline 5 until the background vacuum reaches 5×10 -3 Pa vacuum chamber 3, controlled TiCl 4 The pressure is 100Pa, and a negative voltage of 800V is applied to the collector 1 (cathode) insulated from the vacuum chamber 3 through a DC power supply 9, and the anode 2 insulated from the vacuum chamber 3 generates gas ionization, forming in the region 7 of the two electrodes Glow plasma, under the action of electric field, TiCl 4 The titanium cations in the plasma generated by gas ionization are deposited on the surface of the collector 1 made of sponge-like titanium, and the chlorine gas generated by the discharge is absorbed by the gas collector 8 through the chlorine gas pipeline 6 and stored. After 8 hours of continuous treatment, 1.3Kg of titanium with an oxygen content of less than 0.01% and a chlorine content of less than 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com