High sensitivity nano biosensor production method

A biosensor and high-sensitivity technology, which is applied in the field of high-sensitivity nano-biosensor production, can solve the problems of low detection sensitivity and achieve the effect of improving detection sensitivity and enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

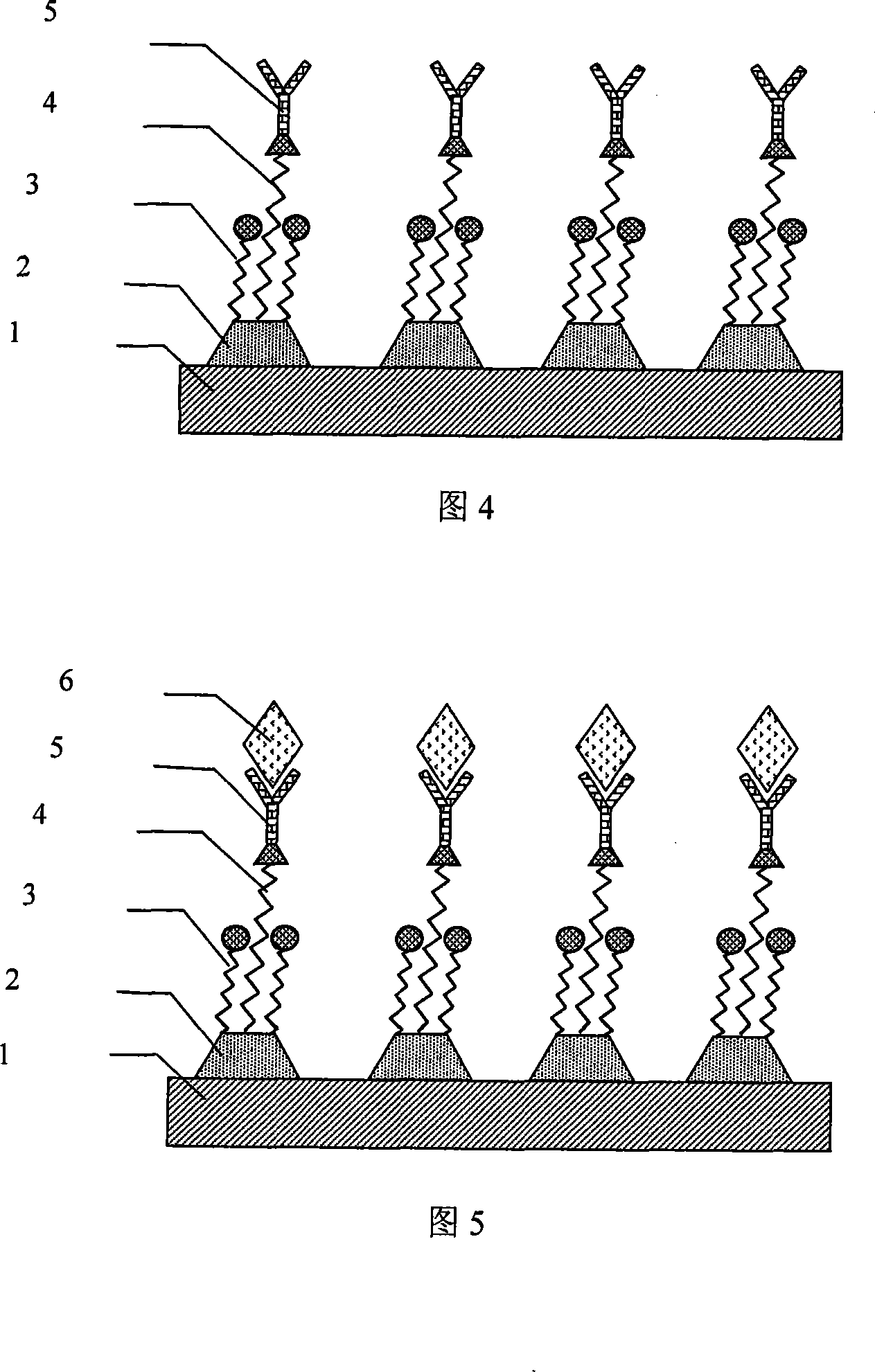

[0031] The specific process of embodiment 1 of the present invention is:

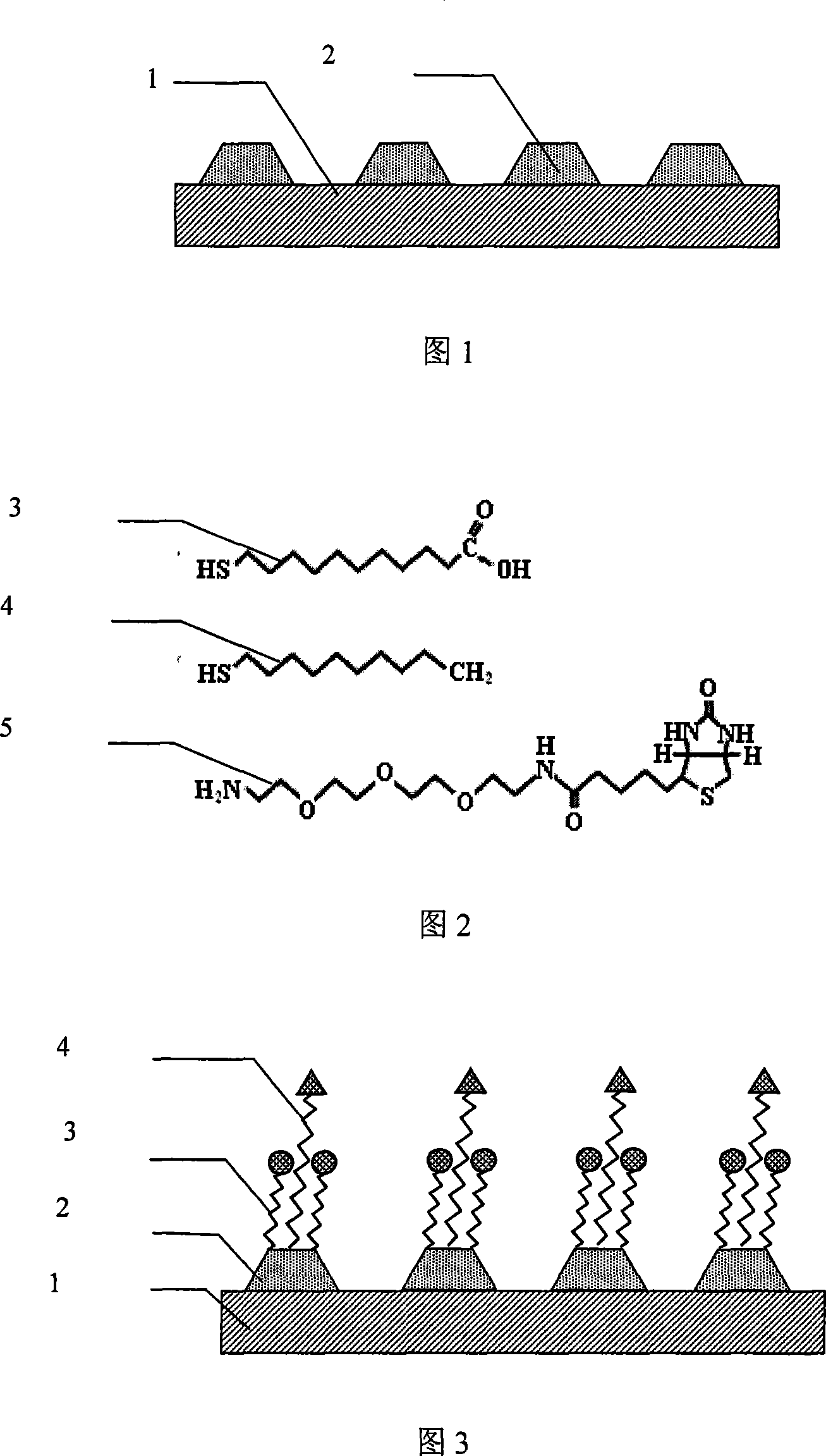

[0032] (1) Utilize the extended nanosphere imprinting (NSL) technology developed in our laboratory to fabricate a diamond-shaped silver nanoarray with an array period of 440nm, a metal silver surface inner width of 140nm, and a surface outer height of 47nm on a K9 glass substrate. The cross-sectional view is as follows As shown in Figure 1;

[0033] The fabrication method of rhombus structure array is as follows:

[0034] (a) Blow dry with nitrogen after thoroughly cleaning the substrate;

[0035] (b) two kinds of monodisperse nanospheres with a diameter of about 440nm and about 200nm are mixed evenly and then added dropwise on the surface of the substrate to realize self-assembly;

[0036] (c) Reactive ion etching (RIE) technology is used to etch the self-assembled monolayer of nanospheres, and the 200nm nanospheres are completely etched away;

[0037] (d) Deposit thickness is the metal silver of ab...

Embodiment 2

[0046] The specific process of embodiment 2 of the present invention is:

[0047] (1) Utilize the extended nanosphere imprinting (NSL) technology developed in our laboratory to fabricate a diamond-shaped silver nanoarray with an array period of 400nm, a metal silver surface inner width of 110nm, and a surface outer height of 50nm on a quartz glass substrate. The cross-sectional view is as follows As shown in Figure 1;

[0048] The fabrication method of rhombus structure array is as follows:

[0049] (a) Blow dry with nitrogen after thoroughly cleaning the substrate;

[0050] (b) two kinds of monodisperse nanospheres with a diameter of about 400nm and about 180nm are mixed evenly and then added dropwise on the surface of the quartz substrate to realize self-assembly;

[0051] (c) Reactive ion etching (RIE) technology is used to etch the self-assembled monolayer of nanospheres, and the 180nm nanospheres are completely etched away;

[0052] (d) Deposit thickness is the metal s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com