P-xylene oxidation reaction operation condition optimization method

A technology of p-xylene and operating conditions, applied in the field of optimization of p-xylene oxidation reactor process operating conditions, can solve problems such as large fluctuations in product quality, limited understanding of PX oxidation reaction and side reaction mechanism, raw material sources and production load changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The description of the following examples will help to understand the present invention, but does not limit the content of the present invention.

[0032] Below in conjunction with accompanying drawing and by embodiment the present invention will be further described:

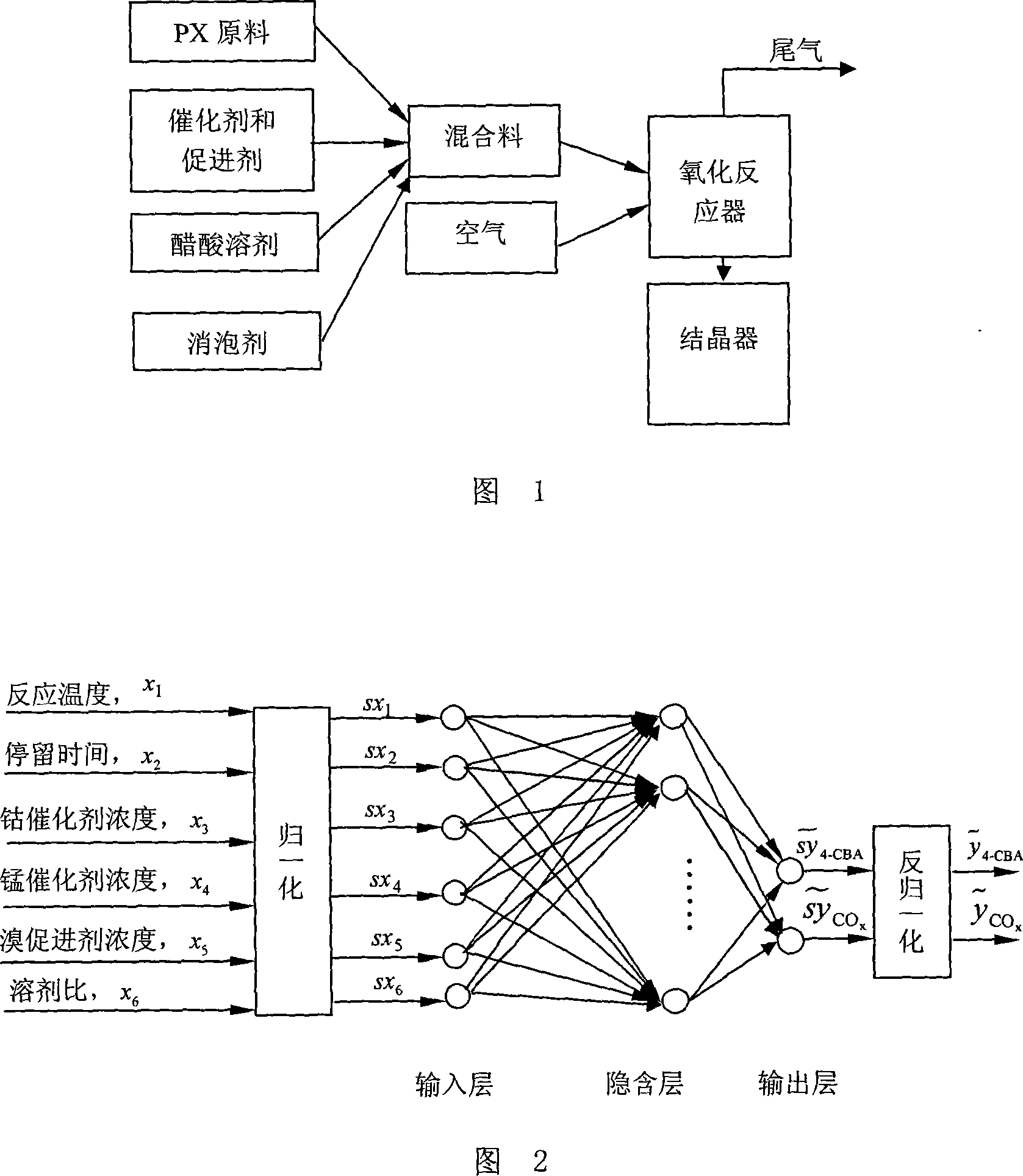

[0033] Figure 1 is a block diagram of the Mitsui Process PX oxidation reaction process. The feed liquid phase mixture stream is sent to the oxidation reactor, wherein the liquid phase mixture stream is acetic acid as a solvent, dissolved with cobalt acetate and manganese acetate as catalyst, hydrogen bromide as accelerator, production raw material PX, and containing part water and defoamer. The oxidation reactor operates at a constant temperature, and the raw material PX reacts with the oxygen in the air entering the reactor to form TA; at the same time, the raw material PX, the intermediate product, the final product TA, and the solvent acetic acid also undergo side reactions with the oxygen in the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com