Medical local film capsule and producing method thereof

A production method and film coating technology, which are applied in the directions of cleaning methods using liquids, sealing with plugs, cleaning methods and utensils, etc., can solve the complex polytetrafluoroethylene film manufacturing process and the difficulty in realizing the composite polytetrafluoroethylene film. Inconvenient promotion and use, to achieve reliable biosafety and biostability, reduce surface insoluble particles, and facilitate promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

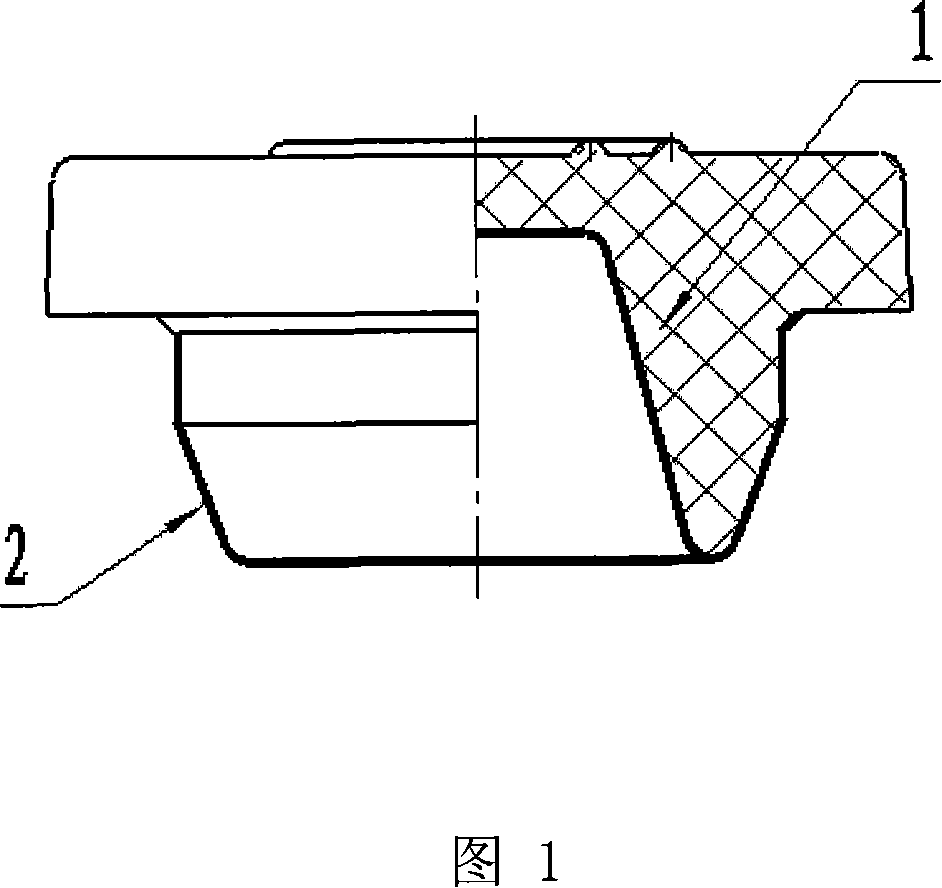

[0017] The specific structure of the present invention is: a medicinal film-coated rubber stopper, comprising a rubber stopper 1, and a coating film 2 of a uniform polychlorinated p-xylylene film is deposited and coated on the surface of the rubber stopper 1 in contact with the medicine. The medical film-coated rubber stopper 1 is made of natural rubber, isoprene rubber, or halogenated butyl rubber.

[0018] The production method of the present invention is as follows: the formed rubber plug 1 is pretreated, and the stains and lubricating oil on the surface of the rubber plug are removed by soaking with a solvent, or the stains and lubricating oil on the surface of the rubber plug are removed by ultrasonic cleaning. remove.

[0019] The rubber plug 1 after surface pretreatment is fixed on the coating fixture, and then placed in the coating equipment, and a layer of partial coating film 2 is applied by deposition.

[0020] The present invention adopts a vacuum chemical vapor d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com