Preparation method for cell cultivation chip based on ITO glass substance and application thereof

A cell culture and glass substrate technology, applied in the field of glass cell culture chip preparation, can solve the problems of complex processing technology of hydrophobic glass material chips, and achieve the effect of removing CO2 supply, reducing complexity and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

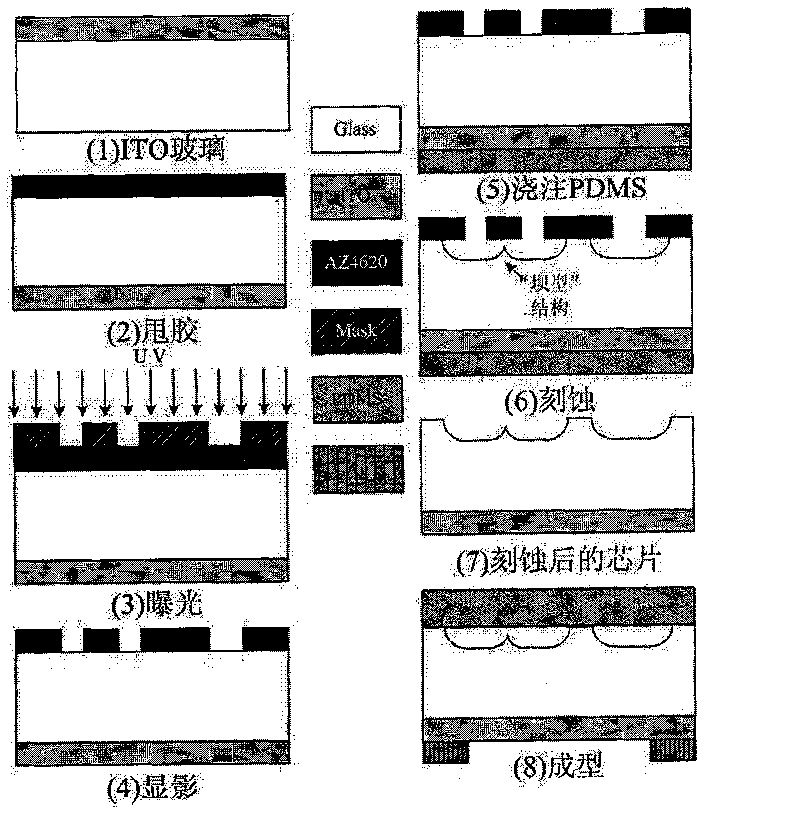

[0032] Cell culture glass chip manufacturing process such as figure 1 As shown, the details are as follows:

[0033] 1. To clean the ITO (Indium-Tin-Oxide, indium tin oxide) glass, first use acetone and alcohol to sonicate for 11 minutes, and then rinse it with deionized water;

[0034] 2. Spin-coat AZ4620 photoresist (2000 rpm, 30 seconds) on the side of the ITO glass where the ITO film is not sputtered, and bake at 80°C for 3 minutes;

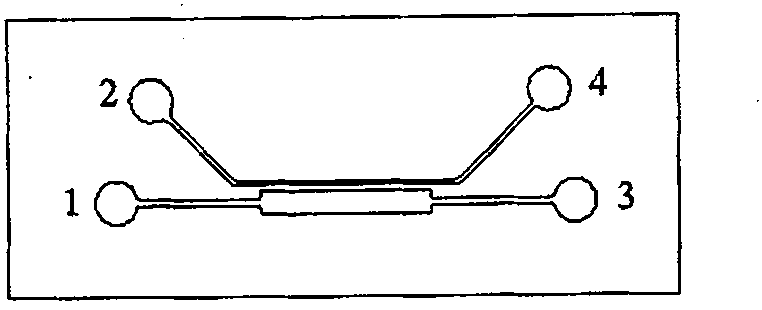

[0035] 3. According to the designed mask (such as figure 2 shown) for exposure;

[0036] 4. Development, post-baking at 130°C, to obtain the graphic structure corresponding to the chip design;

[0037] 5. Mix polydimethylsiloxane (PDMS) monomer and curing agent (sylgard184 product provided by Dow Coming Company) in a weight ratio of 10:1, pour it on one side of the ITO film after degassing for 30 minutes, Curing at 80°C for 1 hour;

[0038] 6. Corrode the ITO glass in 1:6 diluted BOE etching solution for 50 minutes, transfer the pattern...

Embodiment 2

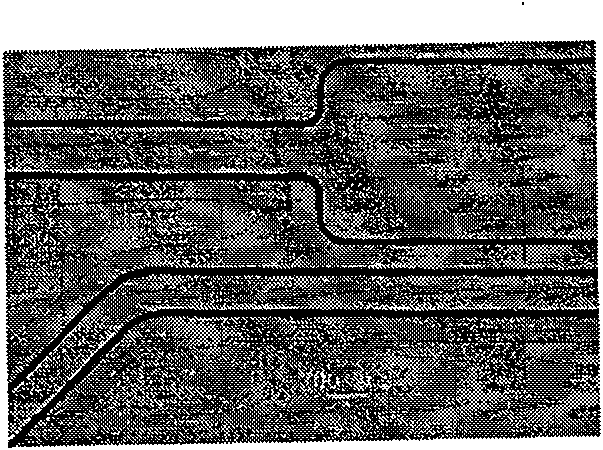

[0044] The 1640 medium was used as the culture medium, which was mixed with the L-15 medium at a ratio of 1:1, and supplemented with 10% fetal bovine serum and 100 Unit / ml streptomycin. Digest routinely cultured PIEC endothelial cells with trypsin digestion solution (containing 0.25% trypsin and 0.02% EDTA), centrifuge to remove the supernatant, disperse and resuspend the culture medium, and adjust the concentration of the cell suspension to 4×10 5 cells / mm3 , and then inhale the cell suspension with a syringe, and slowly inject it into the chip through a syringe pump. The cell-introduced chip is connected with a temperature control device and a culture fluid sampling device to carry out cell culture. The temperature control target was set at 37±0.5°C, and the injection speed of the culture solution was 8 μL / s. The chip is placed under an inverted microscope to observe the growth of cells in real time. Cell culture and observation of microsystems such as Figure 4 shown. ...

Embodiment 3

[0046] The culture medium adopts DMEM (high glucose) medium, which is mixed with L-15 medium at 1:1, and supplemented with 10% fetal bovine serum and 100 Unit / ml streptomycin. Digest conventionally cultured 3T3 cells with trypsin digestion solution (containing 0.25% trypsin and 0.02% EDTA), centrifuge to remove the supernatant, disperse and resuspend the culture medium, and adjust the concentration of the cell suspension to 4×10 5 cells / mm 3 ,, and then inhale the cell suspension with a syringe, and slowly inject it into the chip through a syringe pump. The cell-introduced chip is connected with a temperature control device and a culture fluid sampling device to carry out cell culture. The temperature control target was set at 37±0.5°C, and the injection speed of the culture solution was 8 μL / s. The chip is placed under an inverted microscope to observe the growth of cells in real time. Cell culture and observation of microsystems such as Figure 4 shown.

[0047] Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com