Hydrocarbon hydroprocessing technique

A technology for hydrotreating and process method, applied in refining to remove heteroatoms and other directions, can solve the problems of unfavorable hydrotreating process, low catalyst production efficiency, unable to completely solve the problem of self-heating of sulfided catalysts, etc., so as to shorten the vulcanization time. , suitable for large-scale use, the effect of improving the vulcanization effect

Active Publication Date: 2010-08-18

CHINA PETROLEUM & CHEM CORP +1

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

CN1400056A Coat the pre-sulfurized catalyst containing sulfidation agent with oxygen-containing organic matter containing at least 16 carbon atoms, treat it above 175°C for a period of time, and then activate it with hydrogen to reduce the self-heating problem of the catalyst, but it cannot completely solve the sulfidation state The self-heating problem of the catalyst, and the storage, transportation and loading of the catalyst still have certain problems

In the above-mentioned patents, there is either the problem of self-heating of the catalyst, or the problems of storage, transportation and loading of the catalyst, and there is a problem of low production efficiency in the production of the catalyst, which has an adverse effect on the application of the hydroprocessing process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

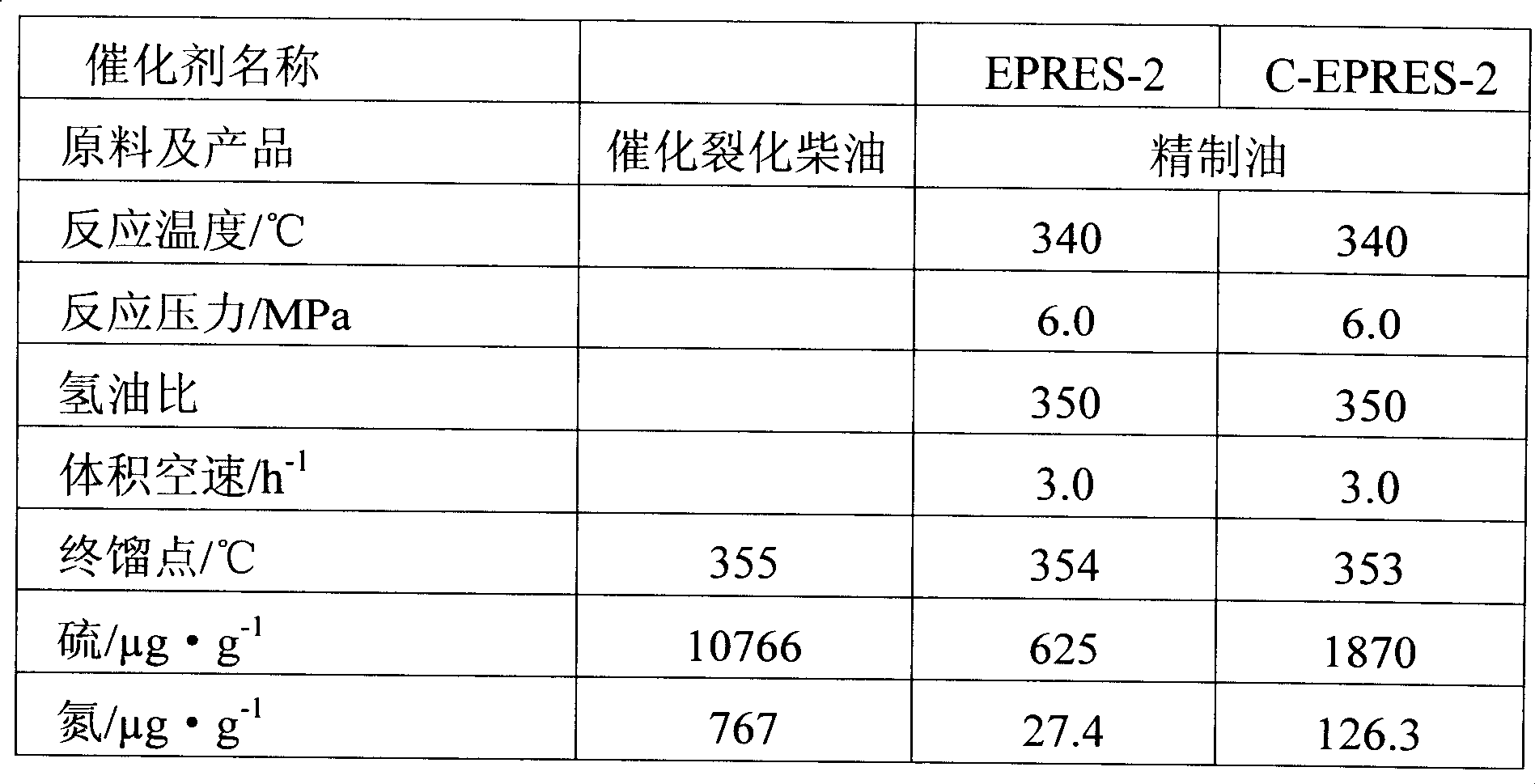

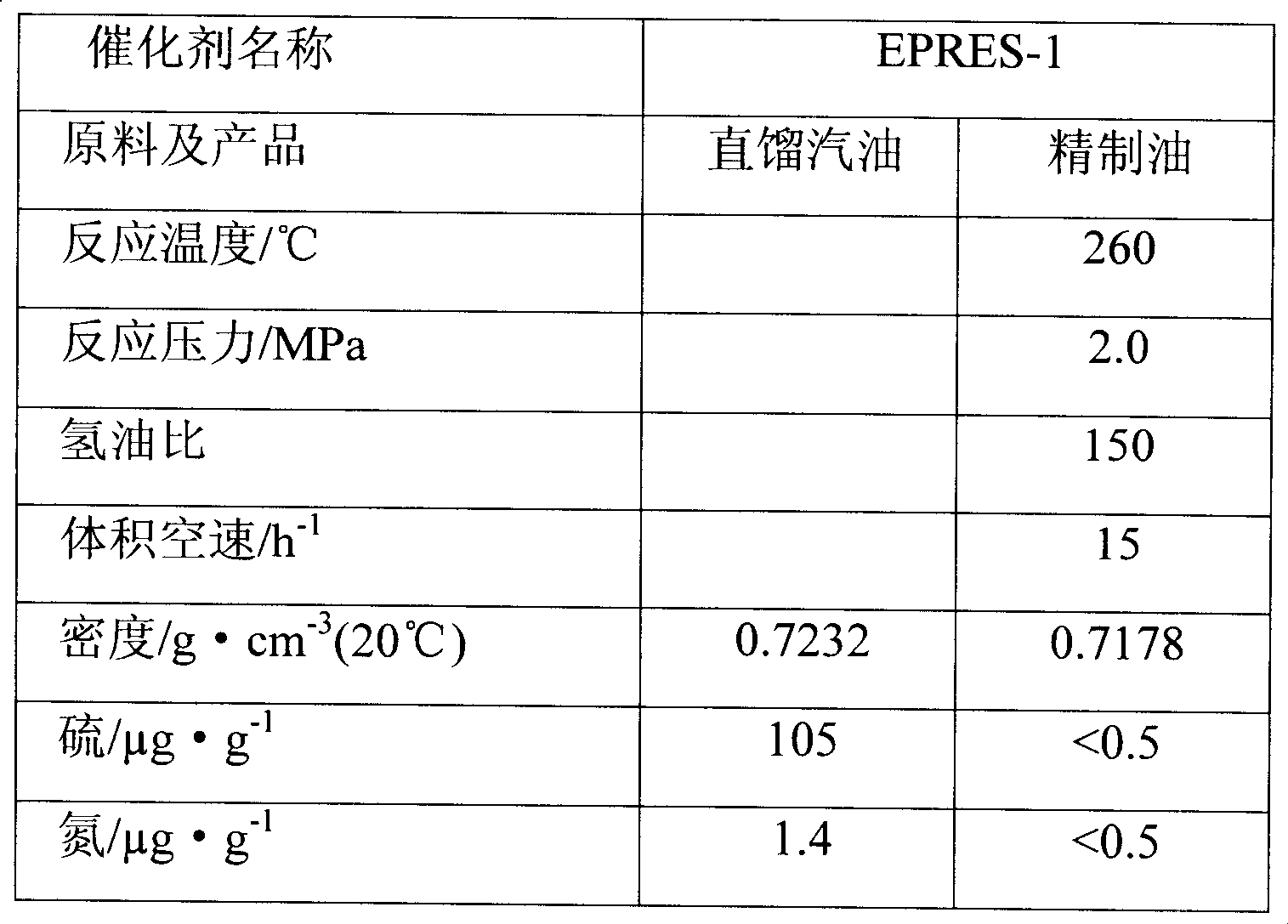

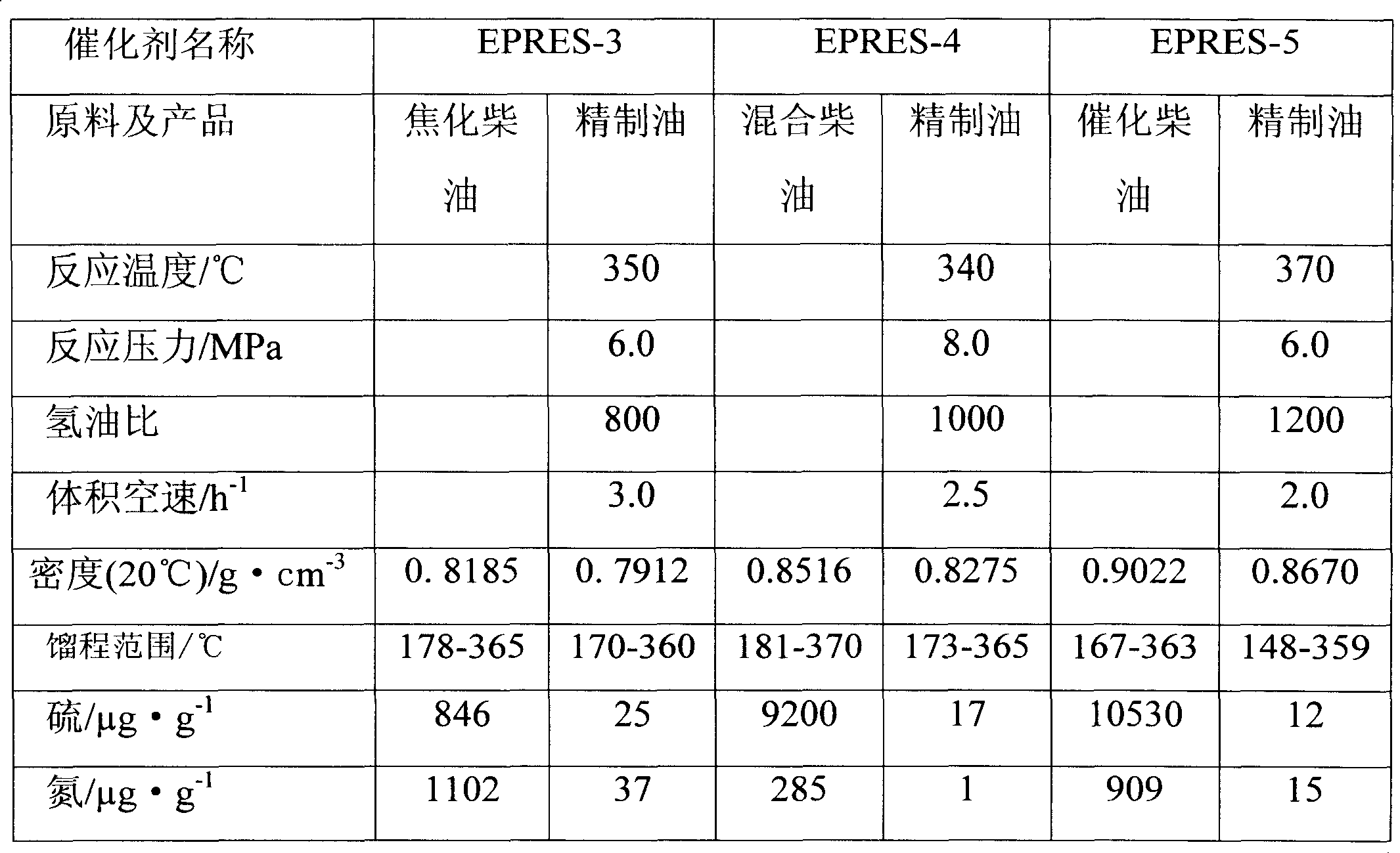

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to hydrocarbon hydrotreating process including the steps of loading catalyst into the reactor, activating, reaction, etc. The hydrotreating catalyst contains thiram matter in 0.5-25 wt% of the catalyst, simple substance sulfur in the amount of 30-150 % of the theoretical sulfur demand of the catalyst, and organic solvent in 0.1-50 wt% of the catalyst. The hydrotreating catalyst with the common action of thiram matter, sulfur and organic solvent has high sulfur holding rate in activation, less concentrated heat release, lowered temperature rise in the catalyst bedand high activity. It may be applied in various kinds of hydrocarbon hydrotreating process.

Description

technical field The invention relates to a hydrocarbon hydrogenation treatment process, in particular to a hydrocarbon hydrogenation treatment process for hydrocarbon raw materials such as impurity removal and upgrading. Background technique The hydrotreating process generally includes hydrofining and hydroupgrading processes. Generally, in the presence of hydrogen, using a suitable reactor form, under certain operating conditions, the hydrocarbon feedstock and hydrogen are contacted with the hydrotreating catalyst. . Hydrotreating catalysts generally use refractory oxides such as alumina, silicon aluminum, and molecular sieves as carriers, and one or more active metal components such as molybdenum, tungsten, cobalt, and nickel, and sometimes phosphorus, silicon, etc. , fluorine, titanium, zirconium, boron and other auxiliary components. Generally, the metal component of the catalyst obtained in the production process exists in an oxidized state, while in the hydrogenation...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10G45/02

Inventor 高玉兰方向晨王刚曹凤兰李崇慧

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com