Grease color acid value integral automatic detection device and method based on computer vision

A computer vision and automatic detection technology, applied in the direction of color/spectral characteristic measurement, food testing, material inspection, etc., can solve the problems of untimely parameter adjustment, low measurement accuracy, non-integrated detection, etc., to improve accuracy and Reliability, improving product quality, and eliminating subjective errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

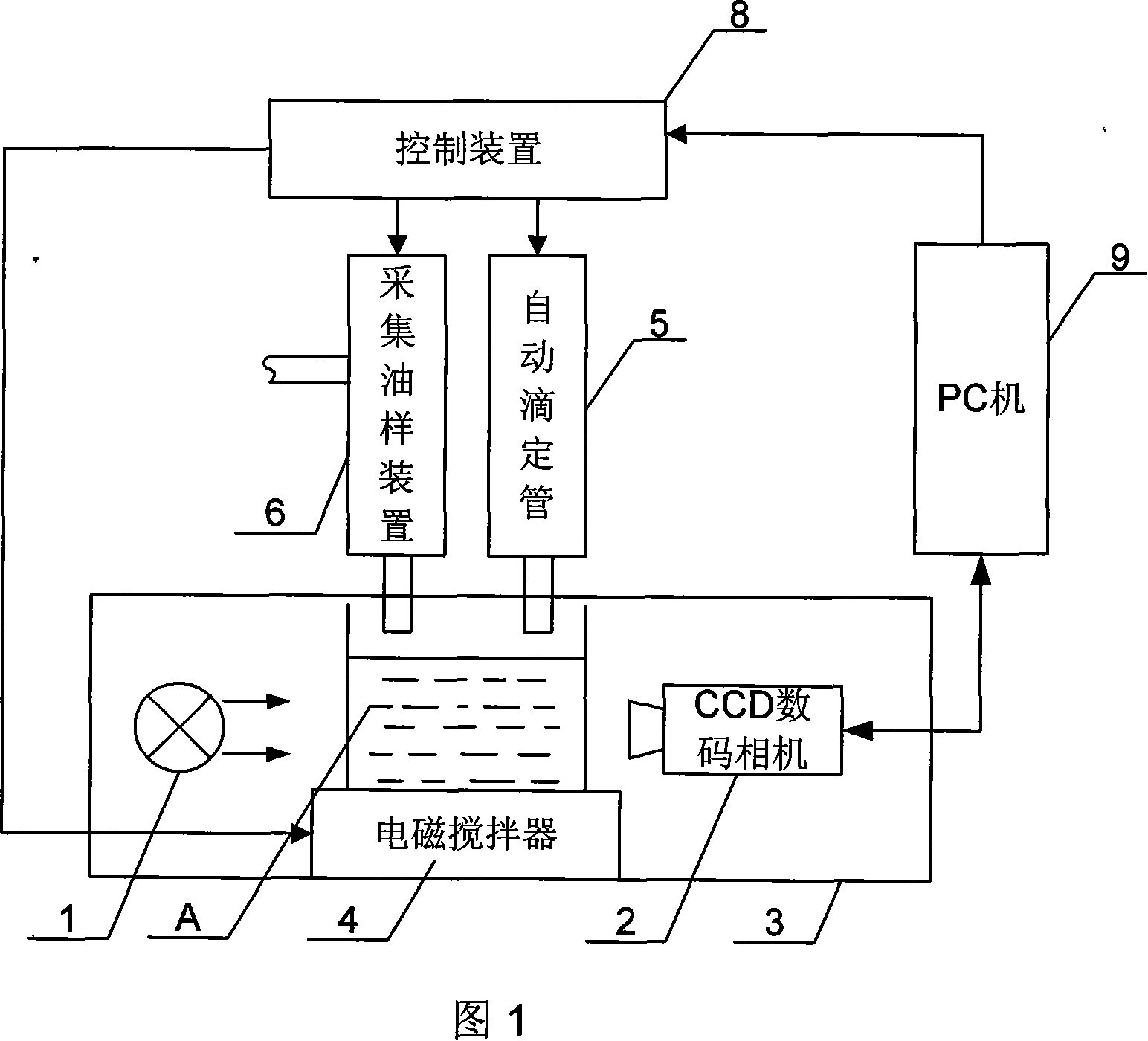

[0031] Specific embodiment one: illustrate this embodiment in conjunction with Fig. 1, this embodiment is made up of image acquisition device, PC 7, control device 8 and executive mechanism; Image acquisition device is made up of light source 1, CCD digital camera 2 and illumination box 3 The actuator is made up of an electromagnetic stirrer 4, an automatic burette 5 and an oil sample collection device 6; the USB interface of the CCD digital camera 2 is connected to the USB interface of the PC 7, and the first RS-232 serial communication interface of the PC 7 is connected On the RS-232 serial communication interface of the control device 8, the three control terminals of the control device 8 are respectively connected to the controlled terminal of the electromagnetic stirrer 4, the controlled terminal of the automatic burette 5 and the controlled terminal of the oil sampling device 6, The light source 1, the sample bottle A to be tested and the CCD digital camera 2 are sequenti...

specific Embodiment approach 2

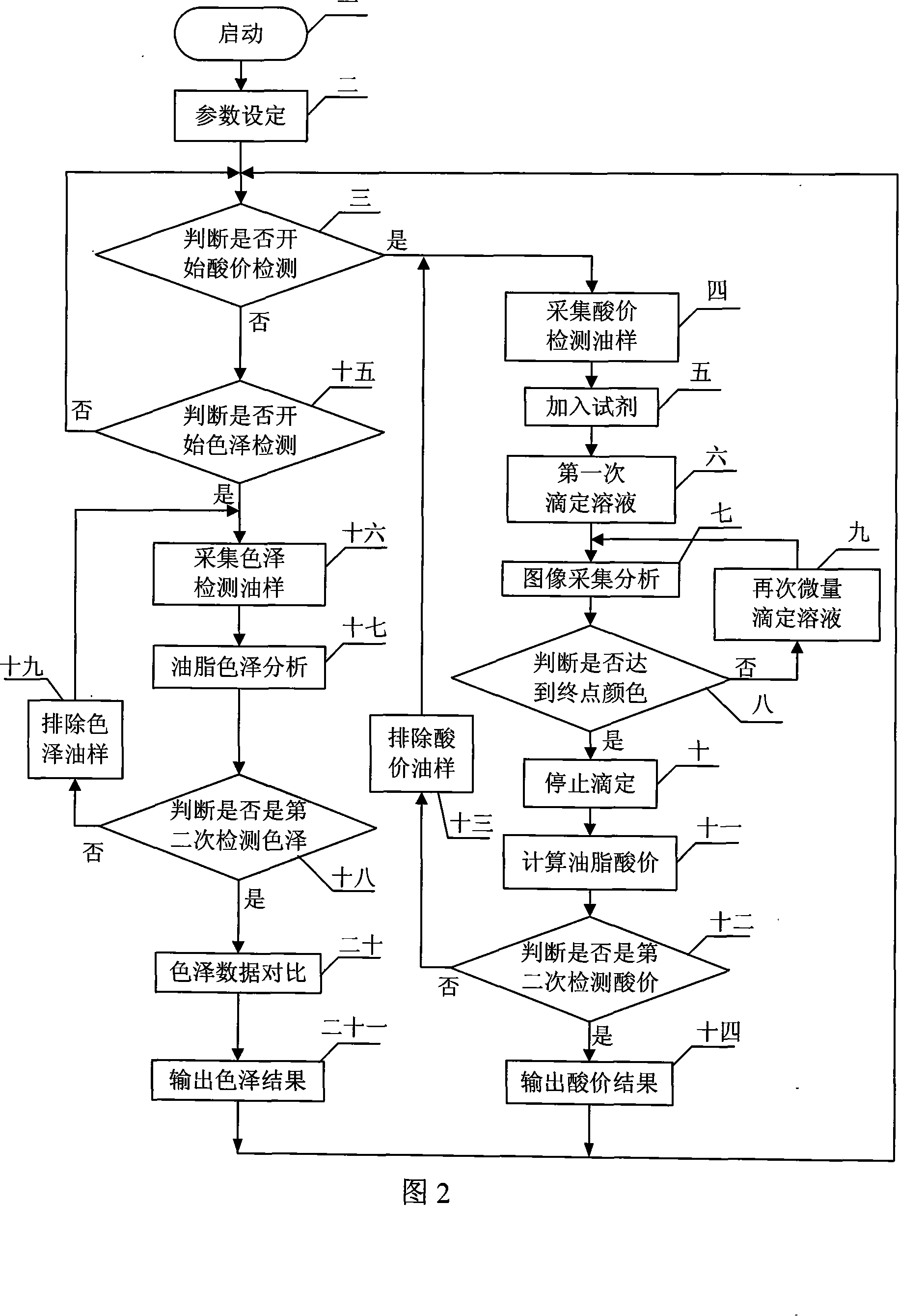

[0032] Specific embodiment two: illustrate this embodiment in conjunction with Fig. 2, the steps of this embodiment are as follows:

[0033] Step 1: Start: system initialization, load the program, and then the system starts to run;

[0034] Step 2: Parameter setting: set the type and level of oil samples collected;

[0035] Step 3: Determine whether to start acid value detection: yes, go to step 4; no, go to step 14;

[0036] Step 4: Collect oil samples for acid value detection: control the oil sample collection device 6 through the control device 8 to pump the oil samples in the final output pipeline of the deacidification process into the sample bottle A to be tested according to the set oil sample quality;

[0037] Step 5: Add reagents: first add neutral ethanol-ether mixed solvent to dilute the oil sample to be tested, and then add phenolphthalein indicator;

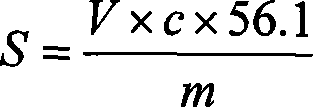

[0038] Step 6: Titration solution for the first time: carry out potassium hydroxide or hydrogen in the sample bo...

specific Embodiment approach 3

[0054] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the storage parameter module in the PC 7 is stored in the acid value detection according to the type and level set when the collected oil sample quality, the first titration The standard volume V, the standard volume v of microtitration again and the color data of the standard titration end point, as well as the quality and standard color data of the oil sample collected during the color test. Other components and steps are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com