Electric pump micro cavity laser with integrated straight wave guide output

A straight waveguide and laser technology, applied in the field of optoelectronics, can solve the problems of complex process, high precision requirements, and difficult directional output of optical power, and achieve the effect of high output coupling efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

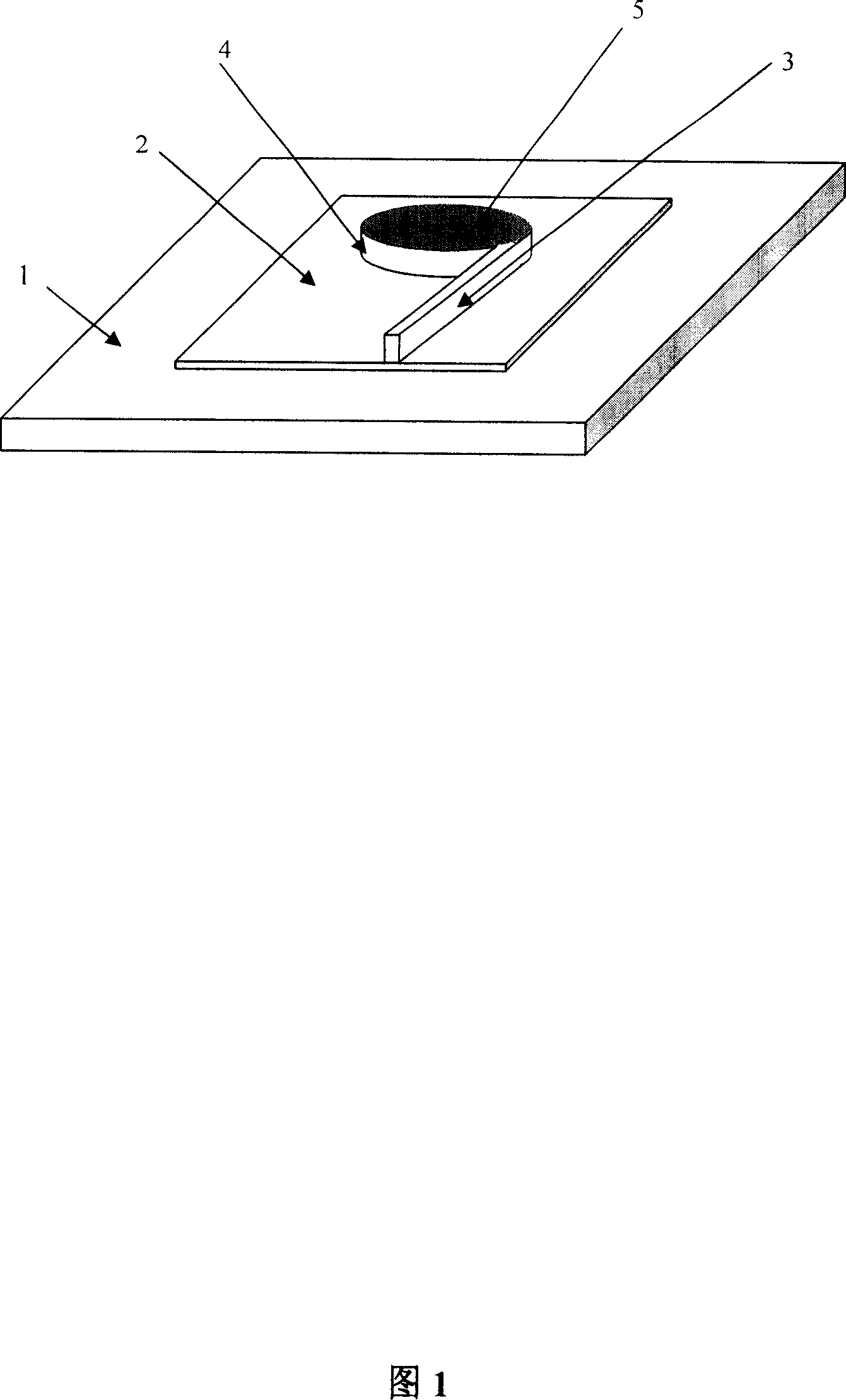

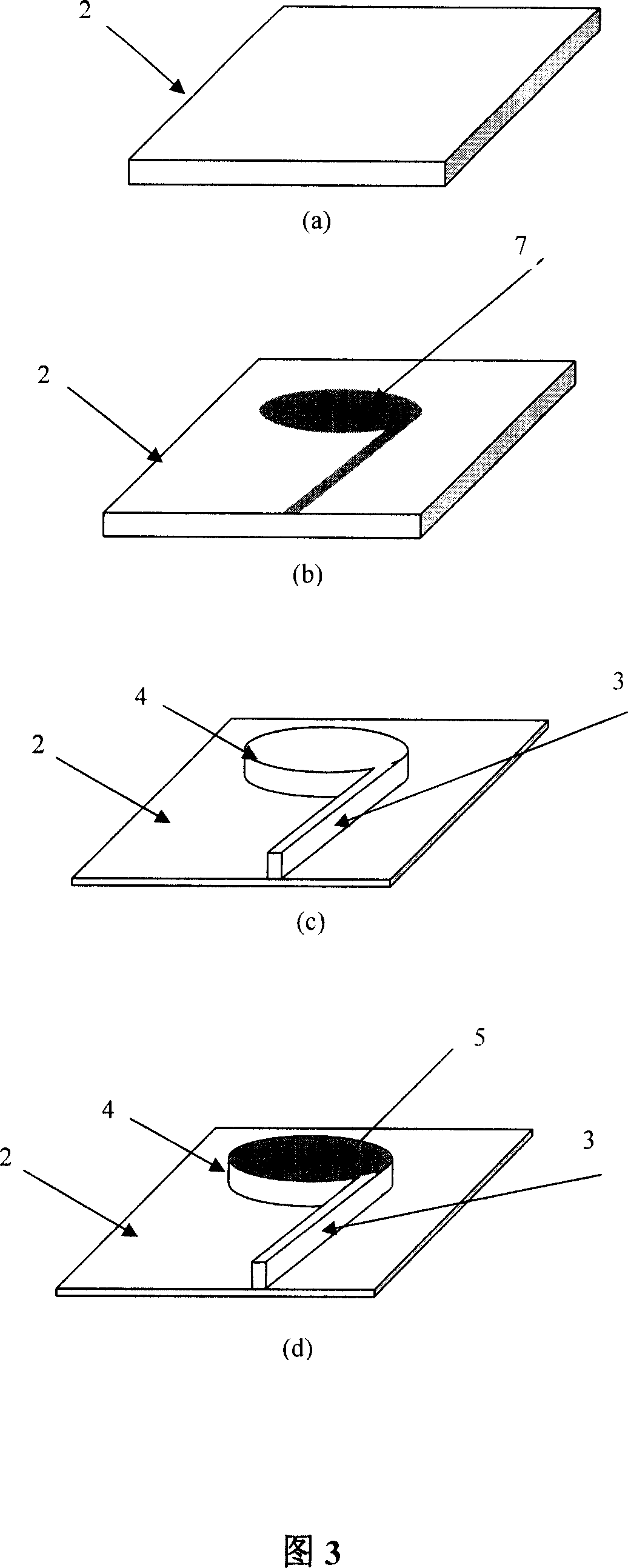

[0018] Fig. 3 is a schematic diagram of the preparation of an electrically pumped microcavity laser with a microdisk integrated output straight waveguide.

[0019] (1), figure (a) is the sample of the semiconductor quantum well laser material grown with MOCVD or MBE technology on the substrate (2), and the thickness of the quantum well laser material is 2-3 microns.

[0020] (2) According to the structural design of the microdisk and the output straight waveguide, a photolithography plate for photolithography is prepared. In this example, the diameter of the microdisk can be designed to be 50 microns, the width of the straight waveguide to be 5 microns, and the length to be 100 microns. Figure (b) uses a photolithographic method to transfer the pattern (7) of the laser to be prepared to the surface of the sample in Figure (a) with photoresist.

[0021] (3), Figure (c) is the sample of Figure (b) after the transfer of the laser pattern, using chemical etching to carve out the ...

Embodiment 2

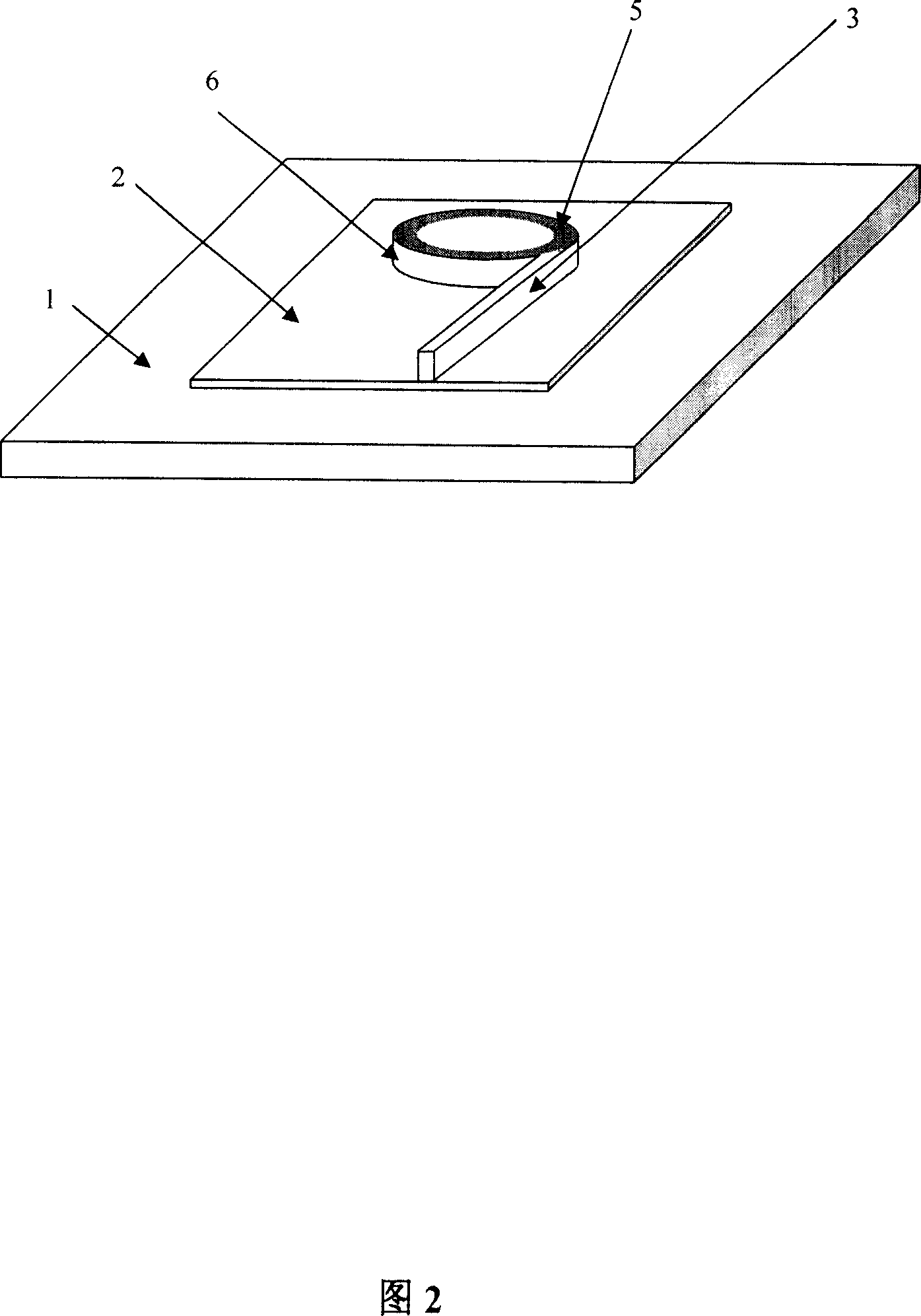

[0026] The manufacturing process of the electrically pumped microcavity laser with integrated output straight waveguide of the microring type shown in FIG. 2 is the same as that of Embodiment 1. The only difference is that the photoresist plate required for pattern transfer in Figure 3(b) is replaced with a photoresist plate prepared according to the structure design of the microring and the output straight waveguide. In this example, the outer diameter of the microring can be designed to be 50 microns, the inner diameter to be 30 microns, and the width of the straight waveguide to be 5 microns and the length to be 100 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com