Bridgeless boost converter with PFC circuit

A boost converter, positive feedback technology, applied in the conversion equipment of intermediate conversion to DC conversion, irreversible AC power input conversion to DC power output and other directions, can solve the problem of energy management circuit complexity, such as the increase of engineers and manufacturers , to achieve the effect of good efficiency, reduced requirements and small effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

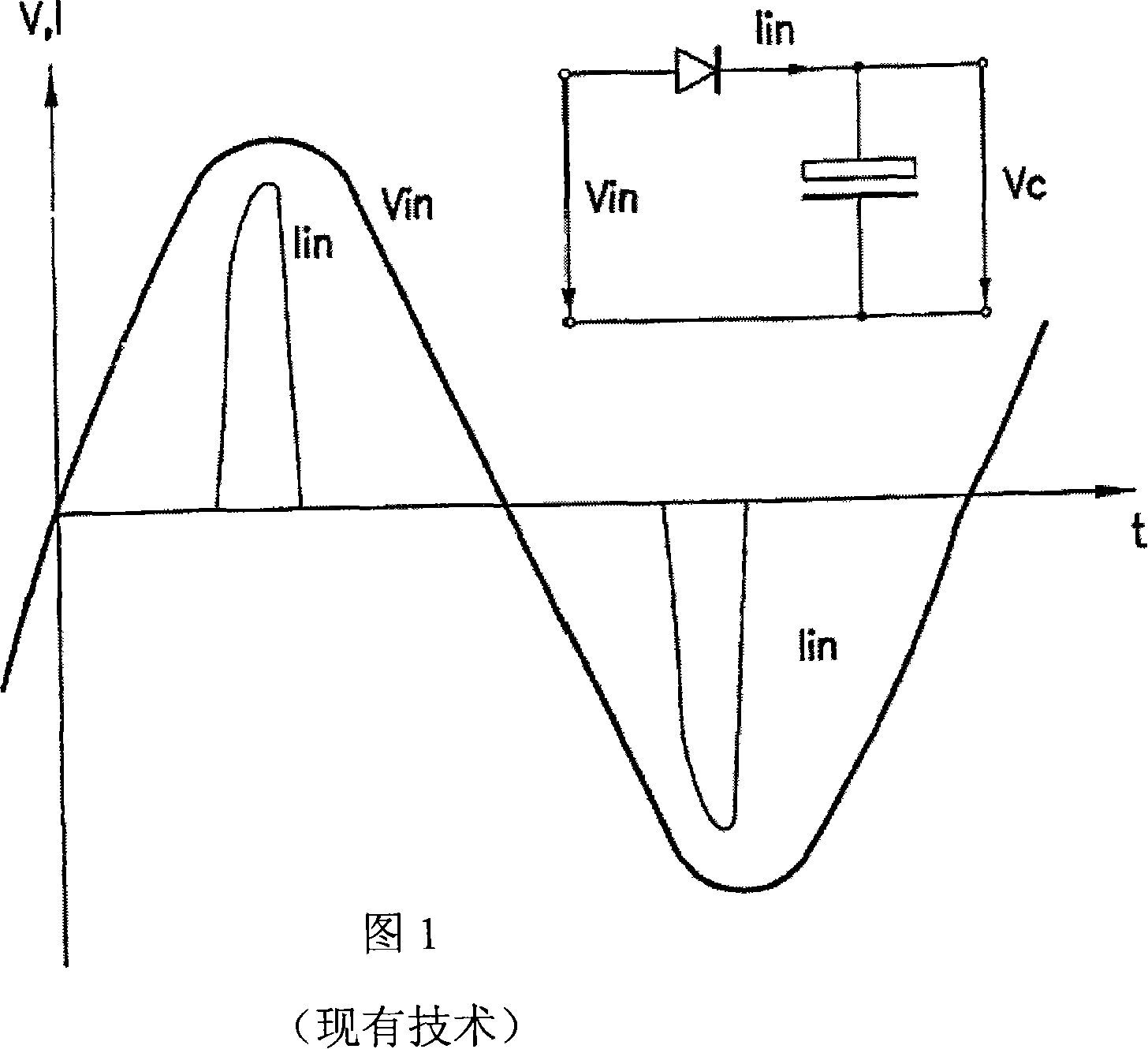

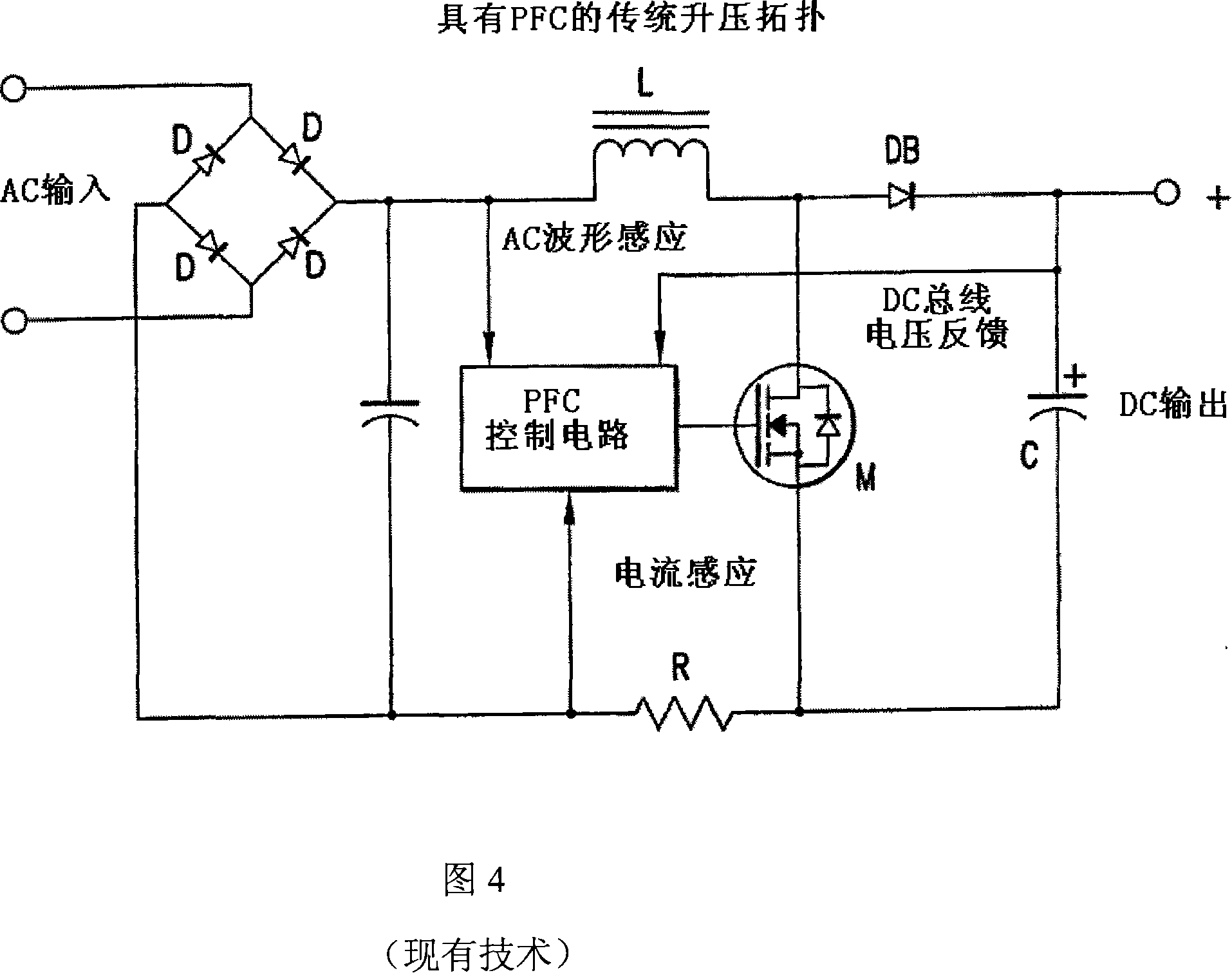

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

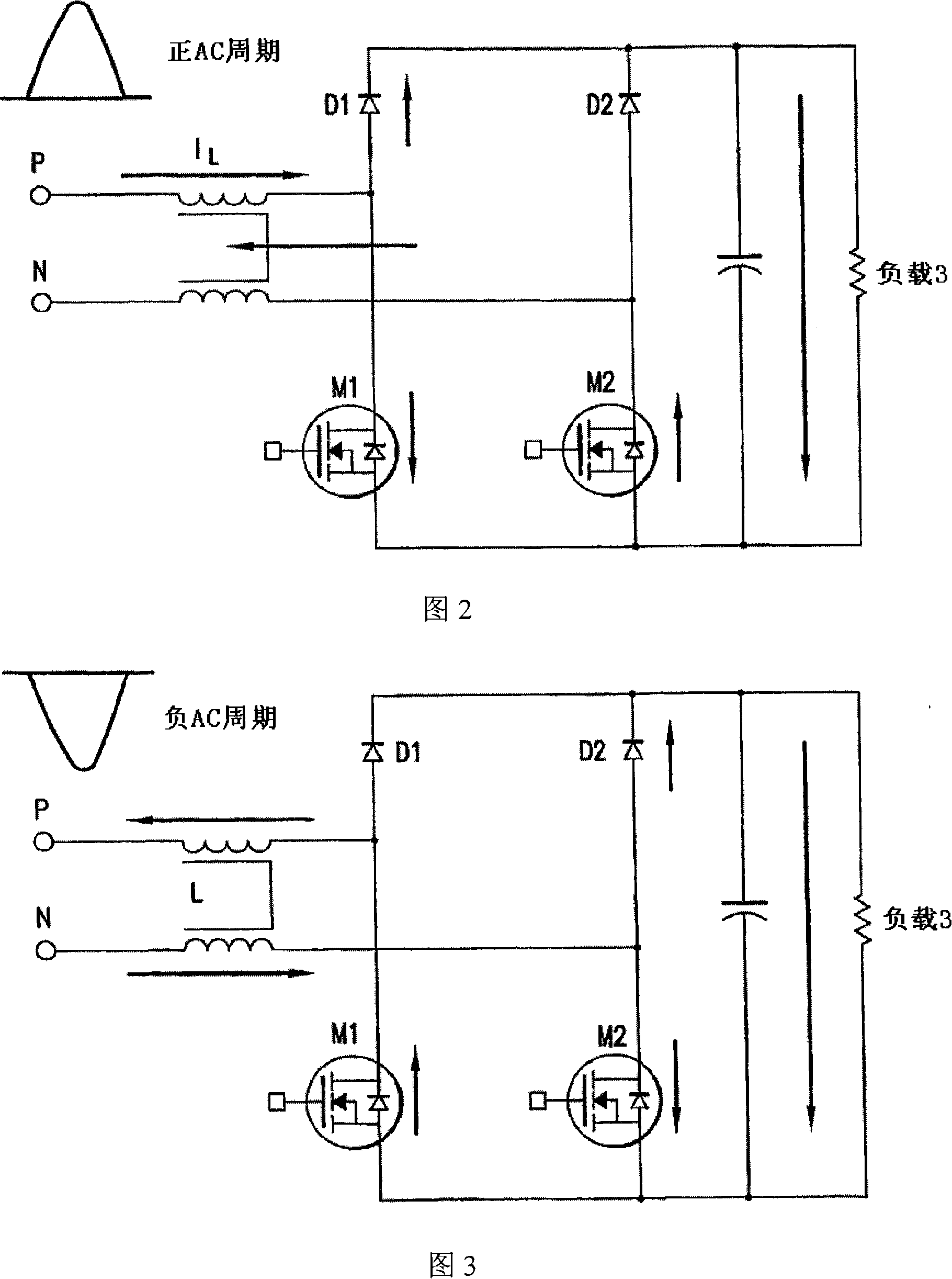

[0059] The circuit of FIG. 5 places the inductor in the AC circuit before the rectifier diodes D1-D4, so that D1 and D3 have dual functions of rectifier and boost diodes. It is obvious that the improved circuit has a smaller diode drop in power flow. Since the circuit runs at 120Hz, switching losses are virtually eliminated, and D1-D4 and Q1-Q2 are standard speed components, which have the added benefit of lower conduction losses than fast semiconductors. Q1 and Q2 may be, for example, IGBTs.

[0060] The controller senses the zero-voltage interleaving of the AC input signal and generates PWM drive signals for IGBTs Q1 and Q2.

[0061] The circuit delivers a power factor greater than 0.99 without current induction with characteristic line variations exceeding + / - 10%. Efficiency > >98% delivering 1KW in a 230VAC circuit at a DC bus voltage of 280V.

[0062] The IGBT switches can be small (crystal area #2) because they only turn on for half the cycle of the turn even if driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com