Chemical mechanical polishing solution for polishing low dielectric materials

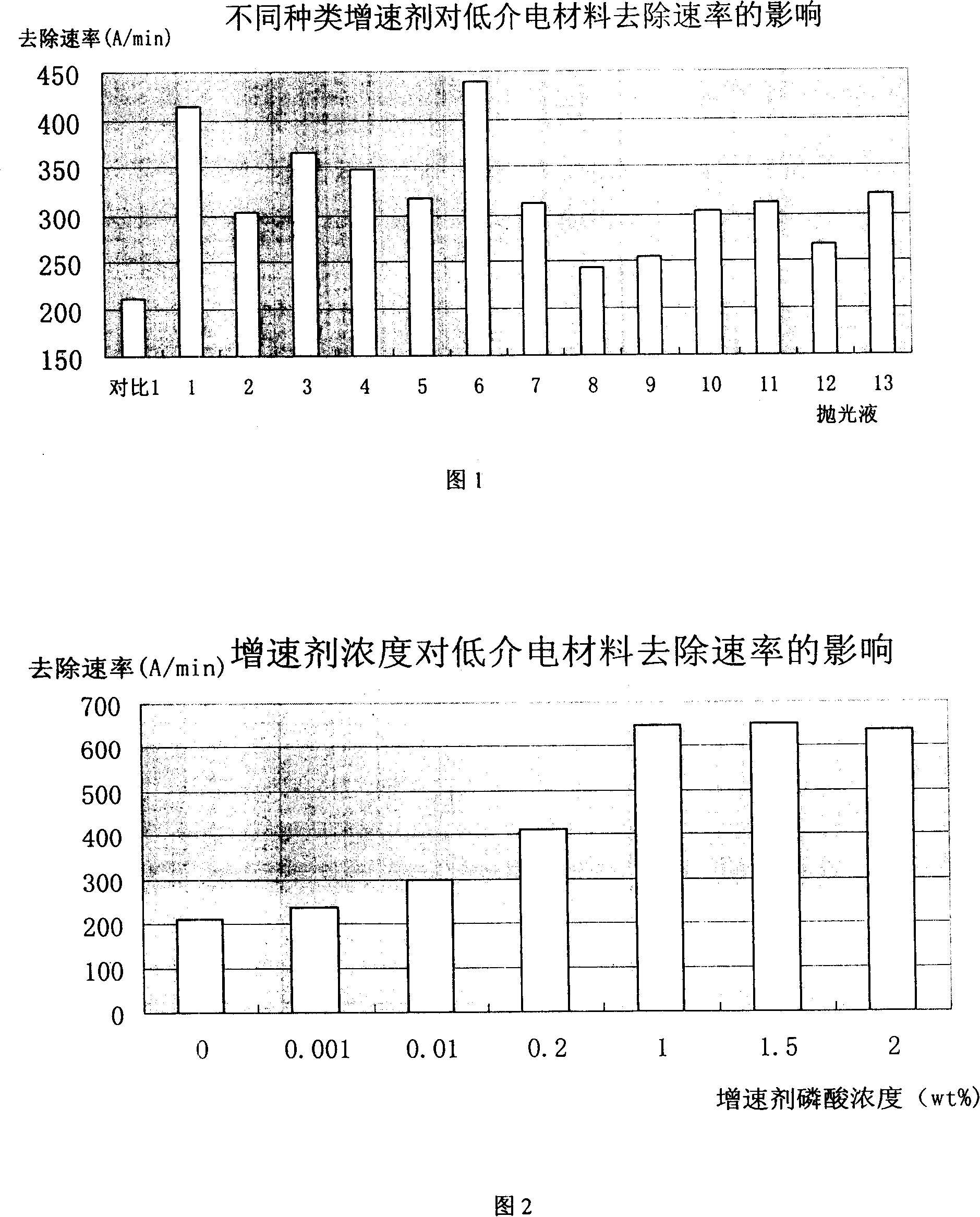

A low-dielectric material and chemical-mechanical technology, applied to polishing compositions containing abrasives, circuits, electrical components, etc., can solve the problems of low removal rate of low-dielectric materials and difficult control of polishing selection, and achieve high removal rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 1% CeO 2 (particle size is 30nm), 0.001% 1-phenyl-5-mercapto-tetrazolium, 0.2% diammonium hydrogen phosphate, 0.001% carbamide peroxide, water as the balance, pH=2.

Embodiment 2

[0022] Example 2 2% Al 2 o 3 (particle size is 20nm), 0.01% 2-mercapto-benzothiazole, 0.2% pyrophosphoric acid, 0.05% peracetic acid, 0.02% polyacrylic acid (molecular weight is 3000), water is the balance, pH=3.

Embodiment 3

[0023] Example 3 10%TiO 2 (particle size is 150nm), 0.2% benzimidazole, 0.2% polyphosphoric acid, 0.5% potassium persulfate, 0.02% polyethylene glycol 200 (molecular weight is 200), water is the balance, pH=4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com