Apparatus for manufacturing semiconductor device, wet etching process device and wet etching process method

A technology of etching treatment and manufacturing method, which is applied in the direction of semiconductor/solid-state device manufacturing, manufacturing microstructure devices, microstructure devices, etc., which can solve the problems of undercutting increase and achieve the effect of reducing undercutting and inhibiting fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

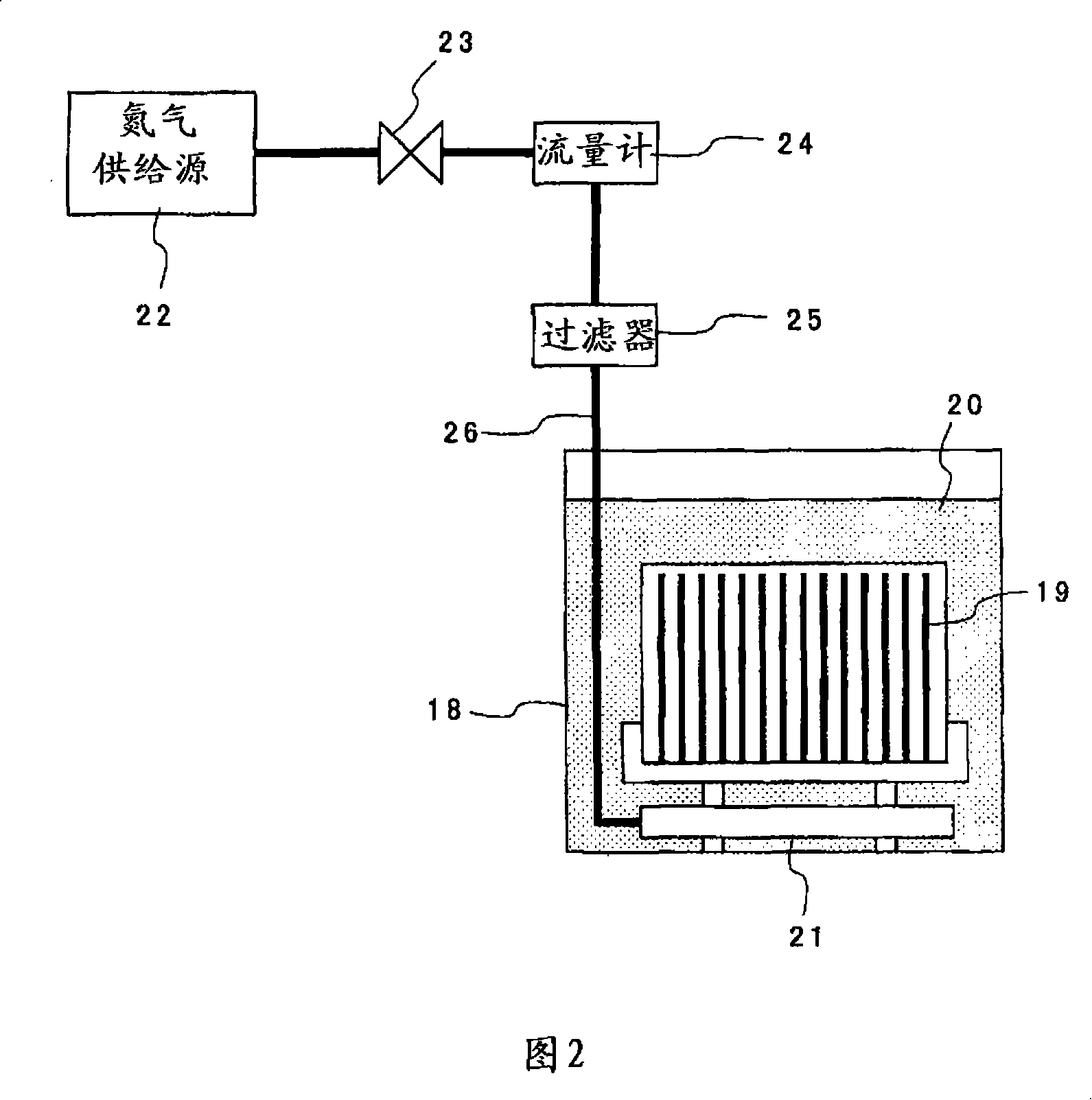

[0029] Hereinafter, the best mode for carrying out the invention will be described in detail with reference to FIGS. 4 to 7 . 4 is an explanatory diagram showing a schematic configuration of a wet etching apparatus according to an embodiment of the present invention. The wet etching apparatus according to this embodiment has an etching solution tank 118 that stores an etching solution 118 and performs wet etching on a plurality of semiconductor wafers 119 to be processed. As the etching solution (etchant) 120, a mixed chemical solution of hydrofluoric acid, ammonium fluoride, and acetic acid can be used. Wet etching can be used for the etching of the interlayer insulating film, nitride film, and oxide film after the metal wiring process.

[0030] Near the bottom of the etching solution tank 118, below the semiconductor wafer 119, a bubbler 121 for making nitrogen gas into fine bubbles is arranged.

[0031] The wet etching apparatus according to this embodiment further includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com