Aqueous epoxy resin and preparation method and method for preparing varnish by using aqueous epoxy resin

A technology of water-based epoxy resin and epoxy resin, applied in the direction of epoxy resin coating, coating, etc., can solve the problem of not maintaining the properties of epoxy resin well, and achieve the effect of excellent curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

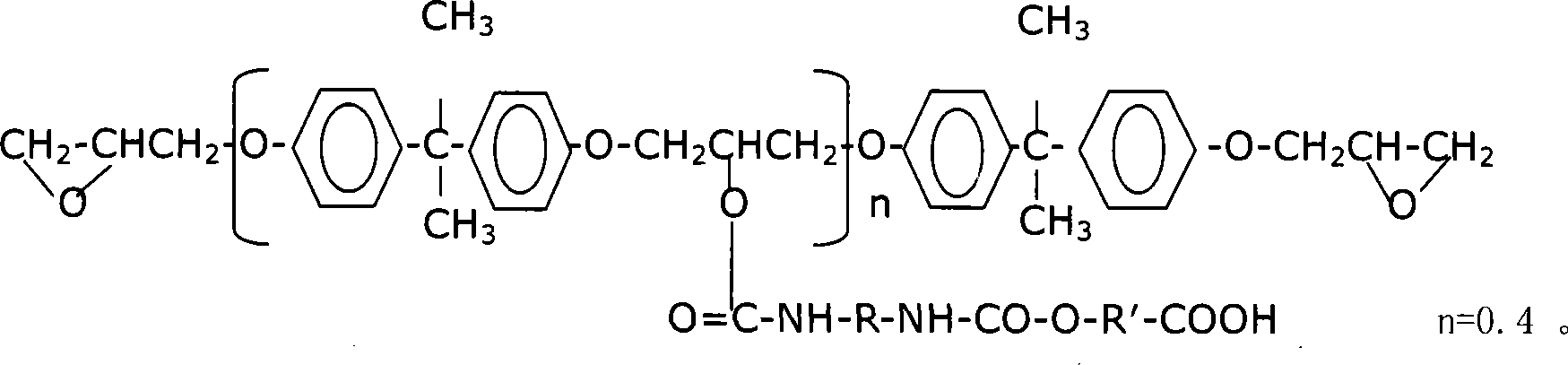

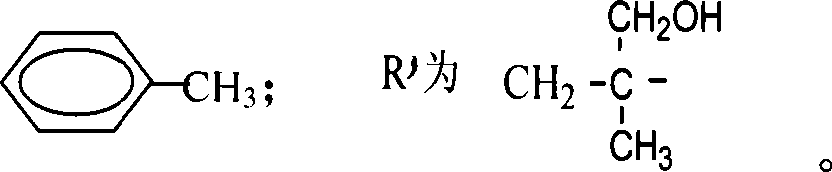

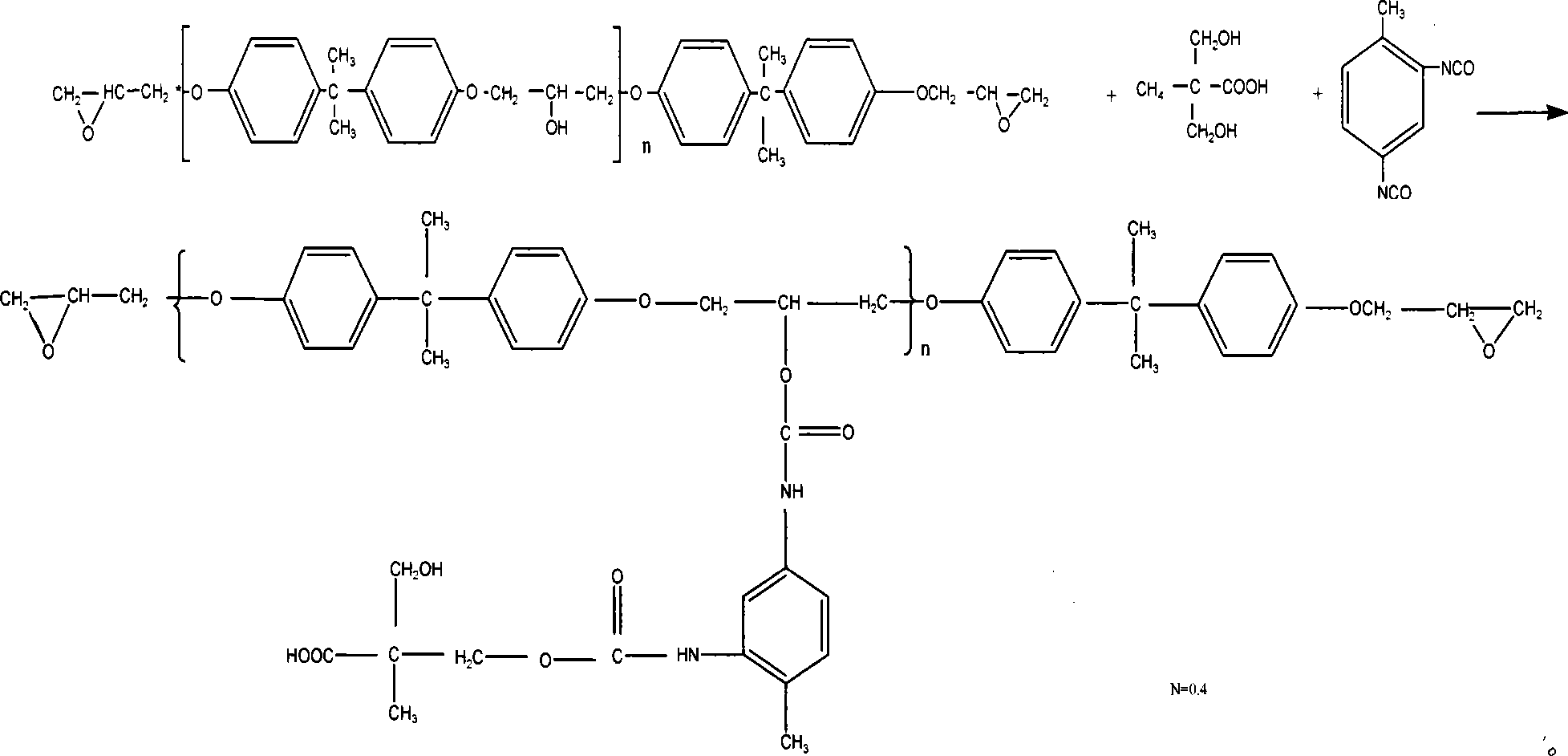

Method used

Image

Examples

Embodiment 1

[0024] Preparation of water-based epoxy resin: Add 10 grams of 2,2-dimethylolpropionic acid, 30 grams of acetone, 17 grams of toluene diisocyanate, 100 grams of epoxy resin E- 44, heated to 60°C, and stopped the reaction at this temperature for 5 hours.

[0025] 100g of the prepared water-based epoxy resin was neutralized with 65g of aqueous sodium hydroxide solution (2g of sodium hydroxide), then it was emulsified with a stirrer, stirred at a high speed for 20 minutes, and the rotating speed was 1000 rpm to obtain a solid content A 60% stable water-based epoxy emulsion.

[0026] Viscosity: 2300mp.s

[0027] Epoxy equivalent: 0.17mol / 100g

[0028] Stability of epoxy resin emulsion: Centrifugal stability: 2000 rpm, no delamination in 30 minutes.

[0029] Preparation of water-based epoxy varnish: take 10g of modified epoxy resin emulsion, cure with 1 gram of diethylenetriamine, stir well until mixed evenly, mature for 5 minutes for coating, the curing condition is normal temp...

Embodiment 2

[0033] Preparation of water-based epoxy resin: Add 12 grams of 2,2-dimethylol propionic acid, 20 grams of acetone, 17 grams of toluene diisocyanate, 100 grams of epoxy resin E- 44, heated to 50°C, and stopped the reaction at this temperature for 6 hours.

[0034] The water-based epoxy resin 100g that will make is neutralized with aqueous sodium hydroxide solution 75g (wherein sodium hydroxide 2.5g), then it is emulsified with a stirrer, stirred at a high speed for 20 minutes, and the rotating speed is 1000 revs / min to obtain a solid 55% stable aqueous epoxy emulsion.

[0035] Viscosity: 2400mp.s

[0036] Epoxy equivalent: 0.19mol / 100g

[0037] Stability of epoxy resin emulsion: Centrifugal stability: 2000 rpm, no delamination in 30 minutes.

[0038] Preparation of water-based epoxy varnish: Take 10g of modified epoxy resin emulsion, solidify with 2g of polyamide, stir well until mixed evenly, mature for 5 minutes for coating, the curing condition is normal temperature (temp...

Embodiment 3

[0042] Preparation of water-based epoxy resin: Add 12 grams of 2,2-dimethylolpropionic acid, 10 grams of acetone, 15 grams of toluene diisocyanate, 100 grams of epoxy resin E- 44, heated to 55°C, and stopped the reaction at this temperature for 5 hours.

[0043] 100g of the prepared water-based epoxy resin was neutralized with 85g of sodium hydroxide aqueous solution (wherein sodium hydroxide 3g), and then it was emulsified with a stirrer, stirred at a high speed for 20 minutes, and the rotating speed was 1000 rpm to obtain a solid content A 50% stable water-based epoxy emulsion.

[0044] Viscosity: 2700mp.s

[0045] Epoxy equivalent: 0.19mol / 100g

[0046] Stability of epoxy resin emulsion: Centrifugal stability: 2000 rpm, no delamination in 30 minutes.

[0047] Preparation of water-based epoxy varnish: Take 10g of modified epoxy resin emulsion, solidify with 2g of urea, stir well until mixed evenly, mature for 5 minutes for coating, the curing condition is normal temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com