Method for preparing multiple phase confusion TiB*-TiC ceramic particle gradient enhancement metal-based complex material

A technology of ceramic particles and composite materials, which is applied in the field of preparation of steel matrix composite materials, can solve the problems of forming pores and failing to give full play to the potential of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

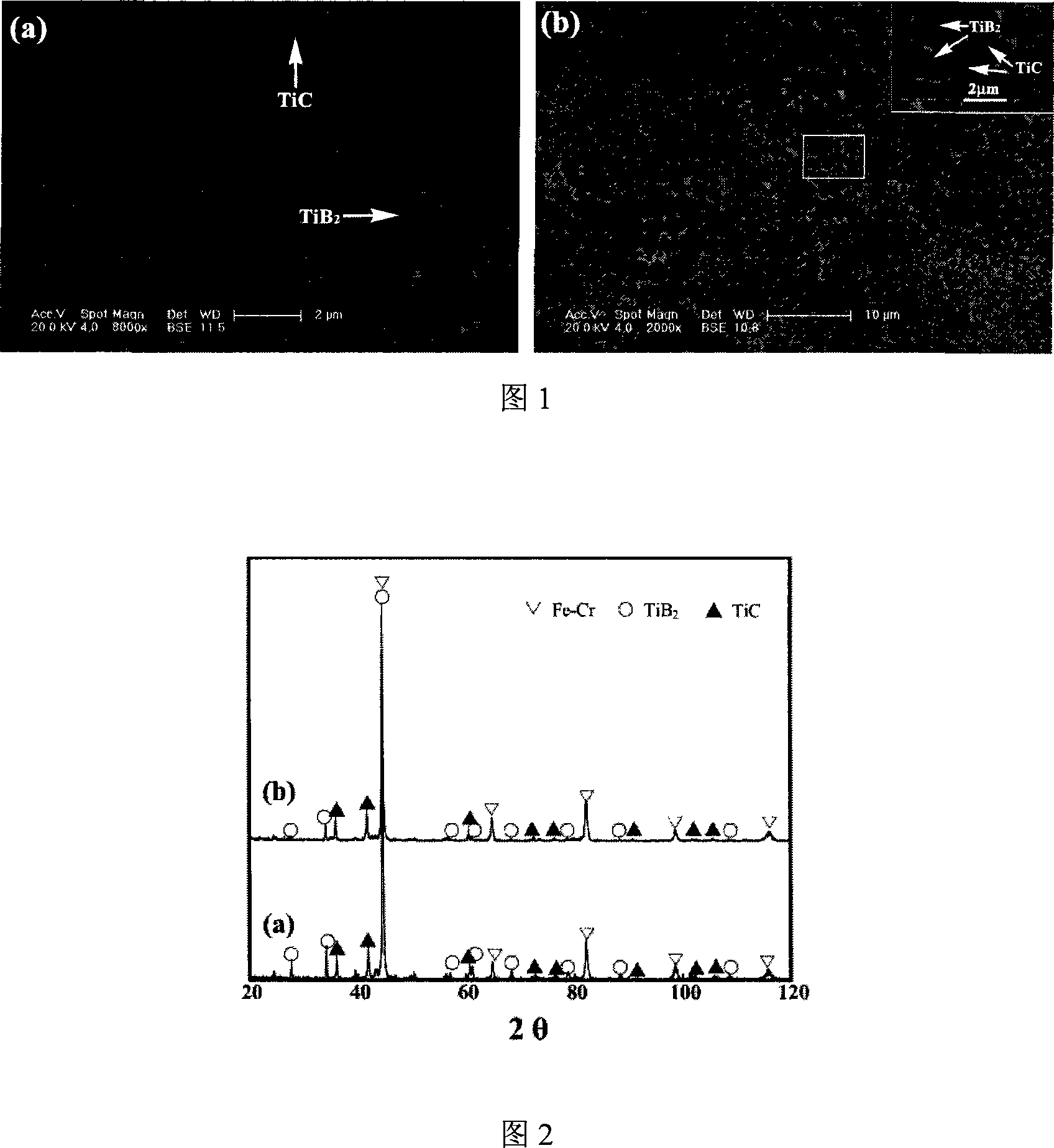

[0022] Multi-phase hybrid TiB prepared by the present invention 2 - TiC ceramic particle gradient reinforced steel matrix composite material, while maintaining the toughness of the matrix alloy material itself, the wear resistance of the gradient reinforced area has been significantly improved. Using 45# steel as the substrate, the multi-phase hybrid TiB was prepared by inducing the combustion synthesis reaction of the green compact in the mold by high-temperature metal molten steel. 2 - TiC ceramic particle gradient reinforced steel matrix composites, the specific preparation parameters and performance data are shown in Table 1. Due to the ceramic particle TiB 2 It is formed by chemical reaction with TiC, the surface is clean, and the bonding strength with the matrix interface is high; the size is small, the shape is regular, TiC is nearly spherical, and TiB 2 It is a hexagonal prism with a high volume fraction of ceramics, and has good production and market application pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com