Device for preparing cobaltosic oxide powder by spray roasting

A technology of cobalt tetroxide and spray roasting, which is applied in the fields of cobalt oxide/cobalt hydroxide, mechanical equipment, lighting and heating equipment, etc. It can solve the problems of poor logistics in roasting furnaces, corrosion of waste acid pumps, waste of materials, etc., and achieve control of furnace temperature The method is complete, the material flow is smooth, and the effect of expanding the adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

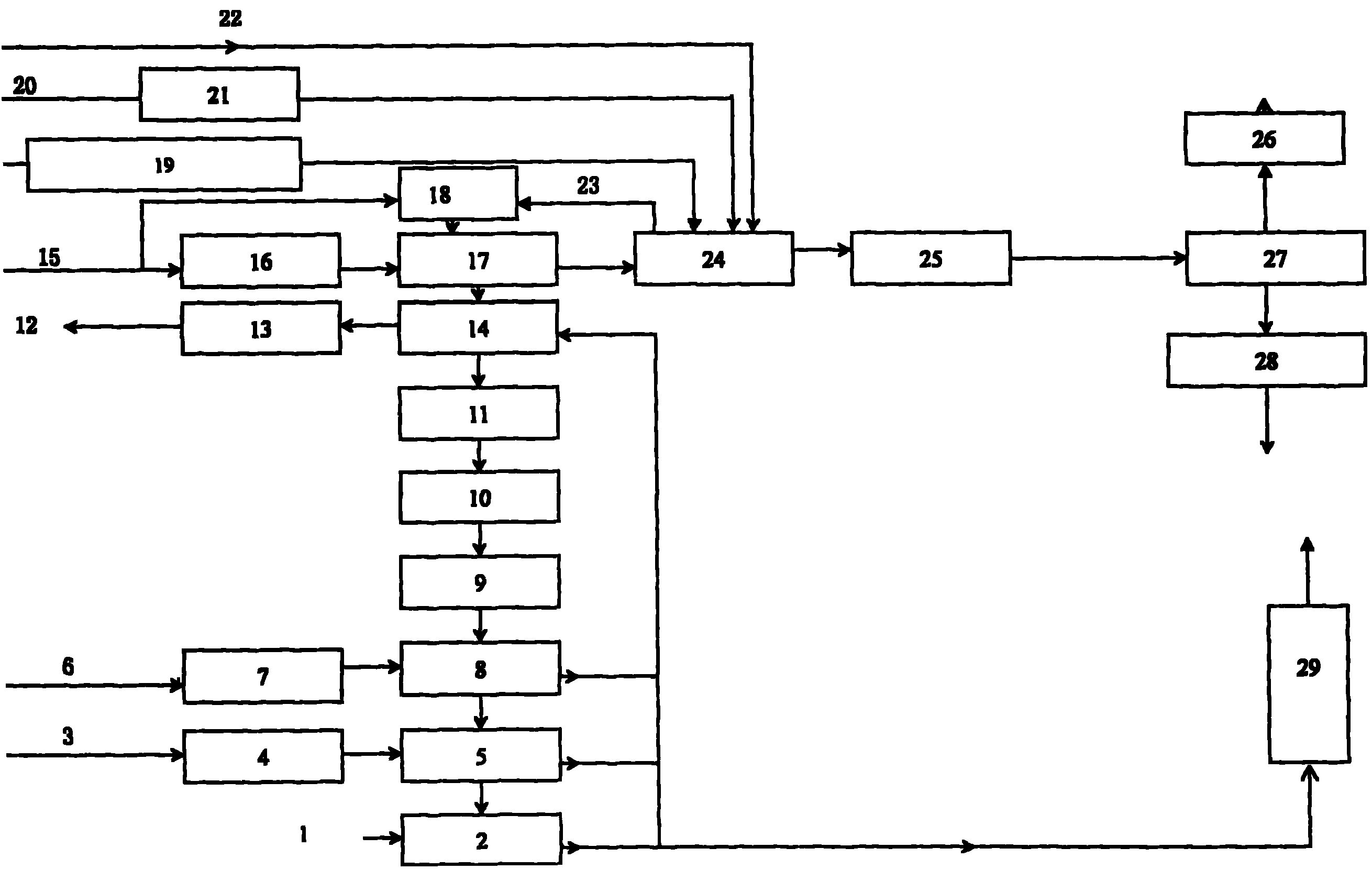

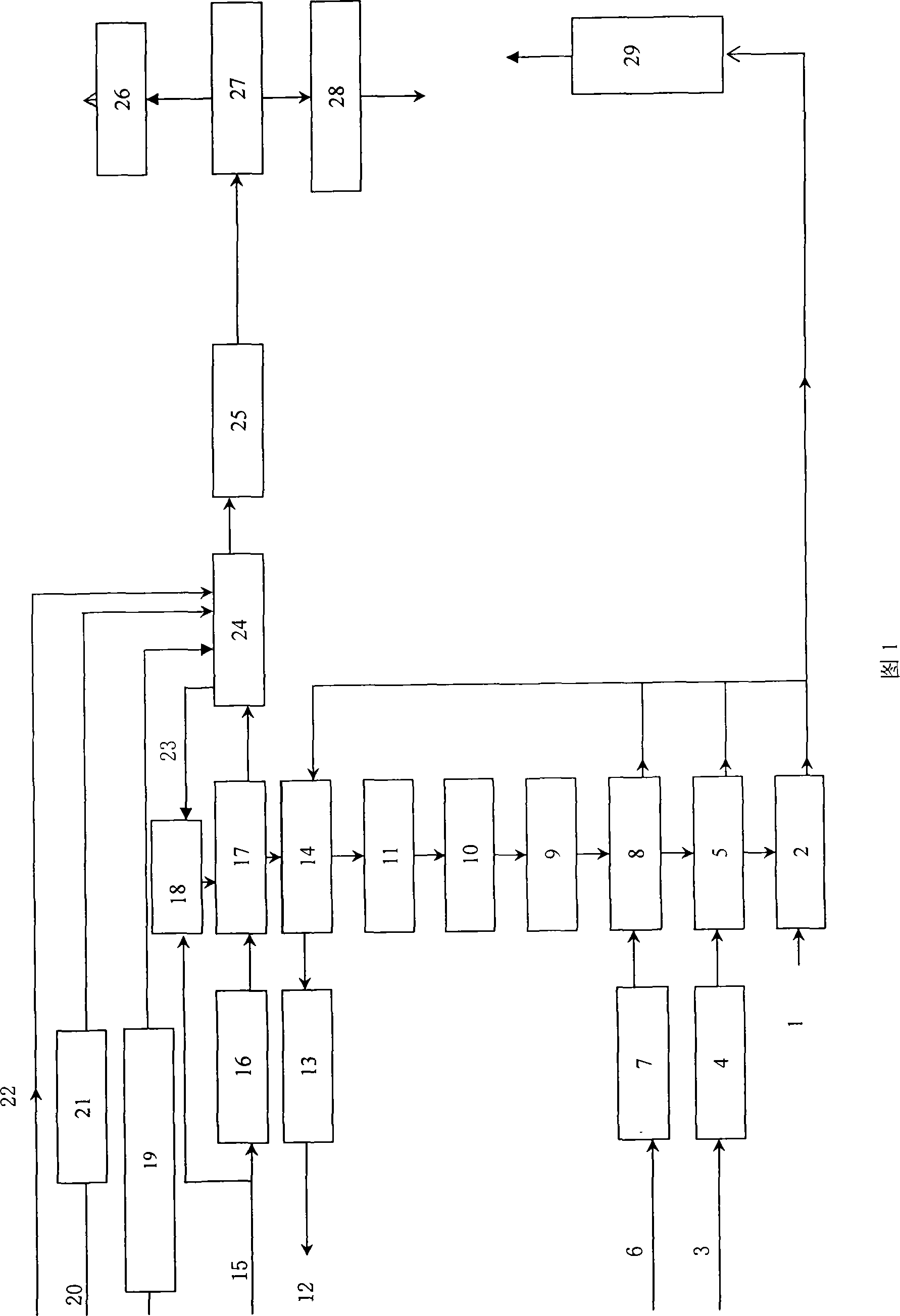

[0042] The specific implementation manner of the present invention will be further described below in conjunction with the examples given in the accompanying drawings.

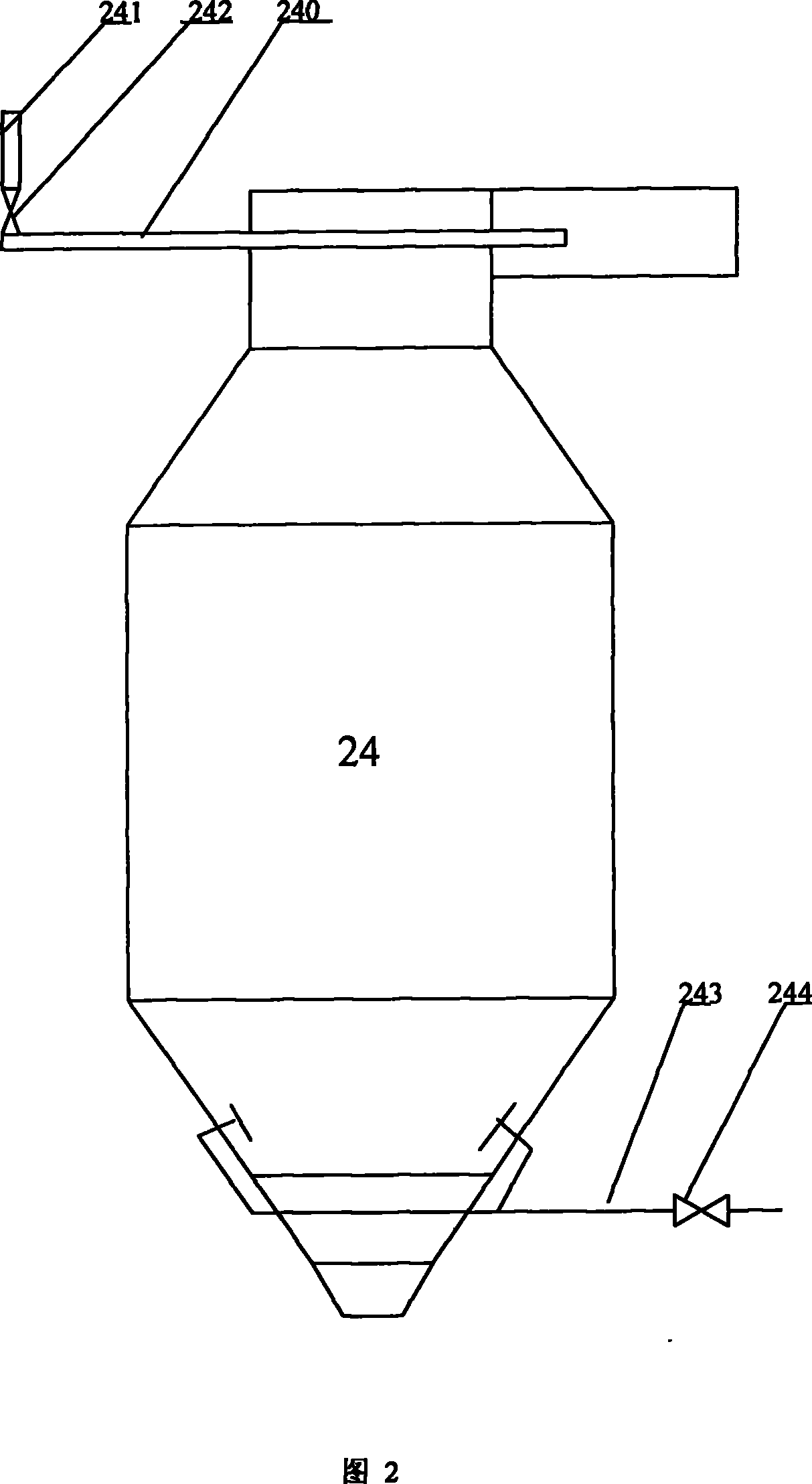

[0043] As shown in Figure 1, the equipment for preparing cobalt tetroxide powder by spray roasting includes a waste acid tank 15 for collecting waste acid, a waste acid filter 16, a pre-concentrator 17, a roasting furnace 24 and a top spraying device thereof, on the roasting furnace body Burners, rotary valves, oxide block breakers at the bottom of the roasting furnace (not shown in the figure), cobalt tetraoxide powder pneumatic conveying and collecting system 27, absorption tower 14, exhaust fan 10, washing towers 8, 5, 2 are arranged tangentially , rinsing water supply device 6, 3, regeneration hydrochloric acid storage tank 13, droplet separator 9, chimney 29, PLC control device, it is characterized in that:

[0044] 1) A dust catcher 18 is set between the waste acid tank 15 and the pre-concentrator 17, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com