Electrooxidation degradation method for dyestuff waste water by using active carbon fibre

A technology of activated carbon fiber and activated carbon fiber felt, which is applied in the field of electro-oxidative degradation of dye wastewater, which can solve the problems of large amount of sludge production and difficult post-treatment, and achieve the effects of small footprint, convenient management, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

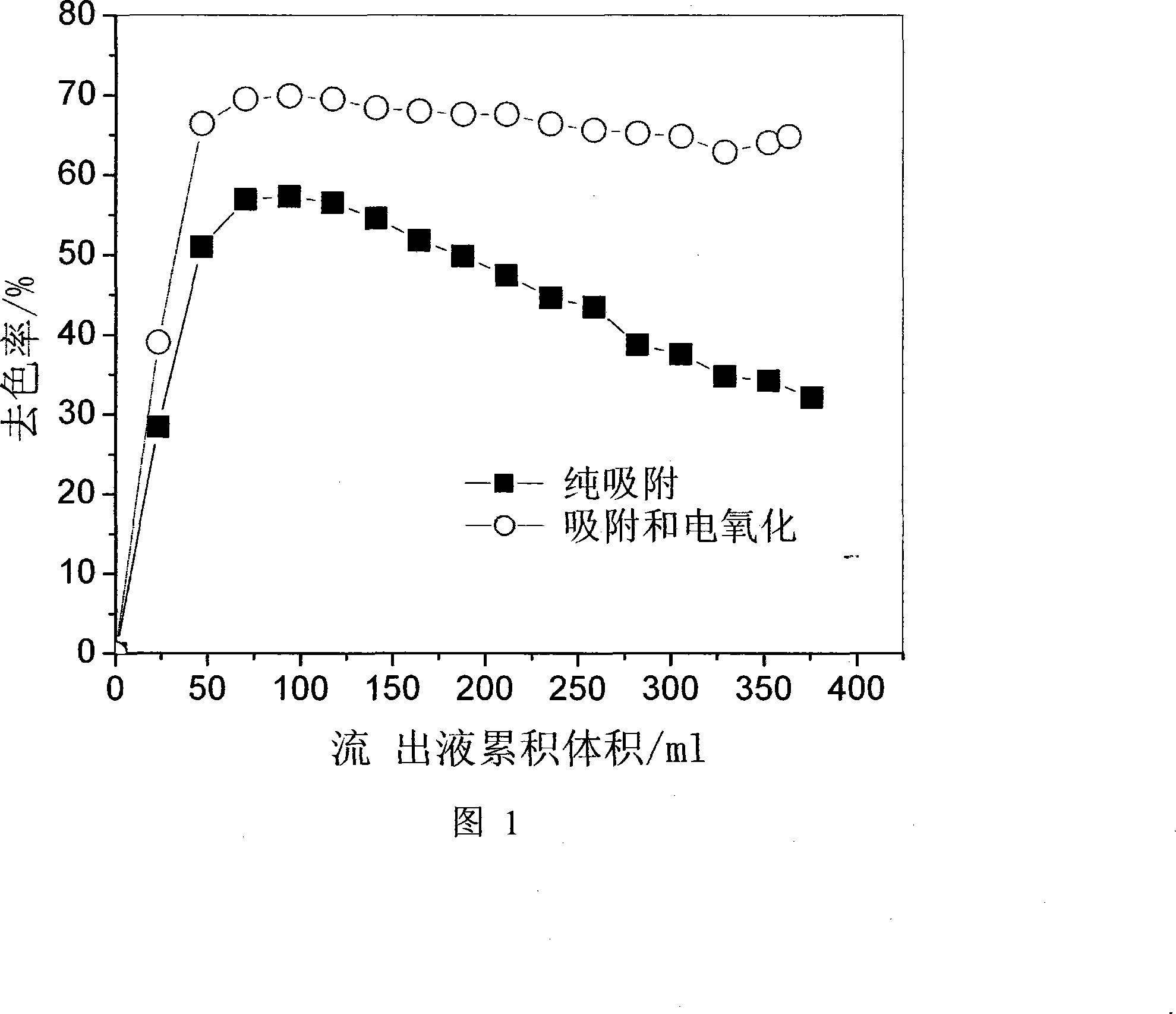

Image

Examples

Embodiment 1

[0022] Embodiment 1. The influence of treatment time on dye removal effect

[0023] Get 50mL concentration and be 700mg / L alizarin red S simulation dye wastewater solution (containing Na 2 SO 4 Concentration 0.1mol / L) in the electrolytic cell, adjust the pH of the solution to be 7, with a mass of 0.251g and a specific surface area of 1256m 2 The viscose-based activated carbon fiber felt in / g is used as the anode, and the stainless steel sheet is used as the cathode. Under the agitation of the stirrer, the constant current density is 25mA / cm 2 Electrolysis was carried out, and samples were taken regularly during the experiment to measure the decolorization rate and COD removal rate of dye wastewater at different treatment times. The color removal rate at 20, 30, 40, and 60 minutes, and the COD removal rate at 60 minutes are shown in Table 1. The results show that under the treatment of the method of the present invention, the decolorization rate of the dye wastewater reac...

Embodiment 2

[0027] Embodiment 2. When using different activated carbon fiber felts with different specific surface areas as anodes, the treatment effect of dye wastewater

[0028] Get 50mL concentration and be 700mg / L alizarin red S simulation dye wastewater solution (containing Na 2 SO 4 Concentration of 0.1mol / L) in the electrolytic cell, adjust the pH of the solution to be 7, use various activated carbon fiber felts with a mass of 0.251g as the anode, and the stainless steel sheet as the cathode, under the agitation of the stirrer, the constant current density is 25mA / cm 2 Electrolysis was carried out, and the decolorization rate and COD removal rate after 60 minutes of treatment were shown in Table 2.

[0029] In addition, a comparative experiment of carbon fiber anode was also done in Example 2, that is, using carbon fiber felt with the same quality as the anode, dye wastewater was treated under the same experimental conditions, and the decolorization rate and COD removal rate is...

Embodiment 3

[0032] Embodiment 3. The influence of the initial pH value of dye wastewater on the treatment effect

[0033] Get 50mL concentration and be 700mg / L alizarin red S simulation dye wastewater solution (containing Na 2 SO 4 Concentration 0.1mol / L) in the electrolytic cell, adjust the pH of the solution to 3-11, with a mass of 0.251g and a specific surface area of 756m 2 / g of polyacrylonitrile-based activated carbon fiber felt is used as the anode, and the stainless steel sheet is used as the cathode. Under the agitation of the stirrer, the constant current density is 25mA / cm 2 Carry out electrolysis, the COD removal rate in the time of 60 minutes is as shown in table 3. The results show that under neutral (pH=7) conditions, the COD removal rate of dye wastewater can reach 73.1% after 60 minutes.

[0034] Table 3 Effect of initial pH value on COD removal rate of dye wastewater

[0035] pH value

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com