Device and method for electrodeionization-electrodeposition treatment and reuse of cyanidation gold extraction tail liquid

A technology of electrodeionization and electrodeposition, applied in chemical instruments and methods, ion exchange water/sewage treatment, special treatment targets, etc., can solve problems such as long process, acid corrosion of equipment, secondary pollution, etc., and achieve good economic benefits , high current efficiency, and zero emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

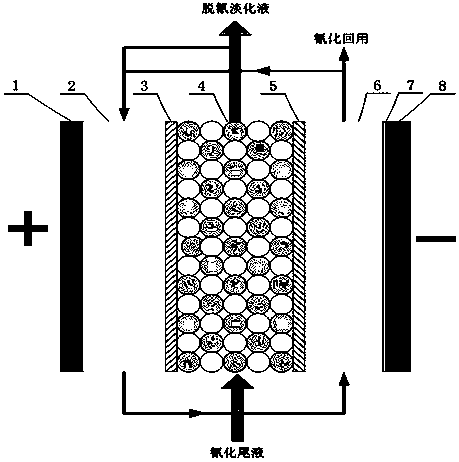

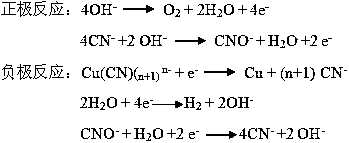

[0028] The electrodeionization-electrodeposition treatment of the present embodiment recycles the device of gold extraction tail liquid by cyanide such as figure 1 As shown, it is composed of a positive electrode chamber 2, an ion exchange chamber 4 and a negative electrode chamber 6. The positive electrode chamber 2 is composed of a positive electrode 1 and an anion exchange membrane 3. The positive electrode material is an iridium-tantalum coated titanium anode mesh, and the positive electrode effective area is 100cm 2 , the positive electrode chamber 2 is filled with an electrolyte solution, the negative electrode chamber 6 is composed of a negative electrode 8 and a cation exchange membrane 5, the negative electrode material is a graphite plate, and the effective area of the negative electrode is 100 cm 2 , fill electrolyte solution in negative electrode chamber 6, described ion exchange chamber 4 is arranged between positive electrode 1 and negative electrode 6, is prov...

Embodiment 2

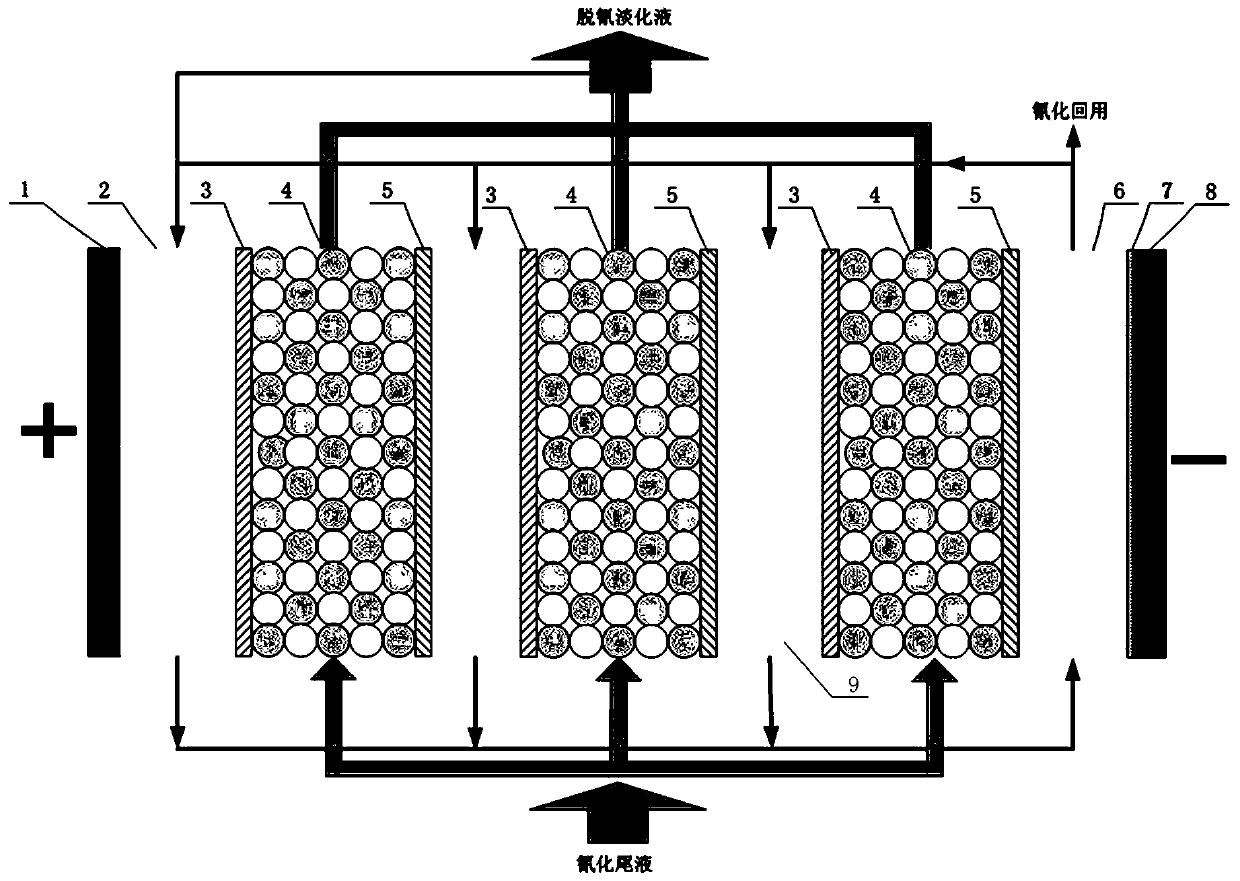

[0035] The electrodeionization-electrodeposition treatment of the present embodiment recycles the device of gold extraction tail liquid by cyanide such as figure 2 As shown, it consists of a positive electrode chamber 2, an ion exchange chamber 4 and a negative electrode chamber 6. The positive electrode chamber 2 is composed of a positive electrode 1 and an anion exchange membrane 3. The positive electrode material is a titanium anode plate, and the effective area of the positive electrode is 100 cm 2 , the positive electrode chamber 2 is filled with electrolyte solution, the negative electrode chamber 6 is composed of a negative electrode 8 and a cation exchange membrane 5, the negative electrode material is graphite felt, and the effective area of the negative electrode is 100 cm 2 The negative electrode chamber 6 is filled with electrolyte solution, and the ion exchange chamber 4 is arranged between the positive electrode 1 and the negative electrode 6. In this embodim...

Embodiment 3

[0042] The electrodeionization-electrodeposition treatment of the present embodiment recycles the device of gold extraction tail liquid by cyanide such as figure 1 As shown, it is composed of positive electrode chamber 2, ion exchange chamber 4 and negative electrode chamber 6. The positive electrode chamber 2 is composed of positive electrode 1 and anion exchange membrane 3. The positive electrode material is titanium anode mesh, and the positive electrode effective area is 50 cm 2 , the positive electrode chamber 2 is filled with an electrolyte solution, the negative electrode chamber 6 is composed of a negative electrode 8 and a cation exchange membrane 5, the negative electrode material is a graphite rod, and the effective area of the negative electrode is 50 cm 2 , fill electrolyte solution in negative electrode chamber 6, described ion exchange chamber 4 is arranged between positive electrode 1 and negative electrode 6, is provided with an ion exchange chamber in the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com