Whole-wet photoresist removing method

An all-wet and wet-process technology, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of increased liquid loss, wafer surface oxidation, and structural disorder, so as to reduce manufacturing time and avoid Effects of ashing damage and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In one embodiment, the degumming method of the present invention comprises the following steps:

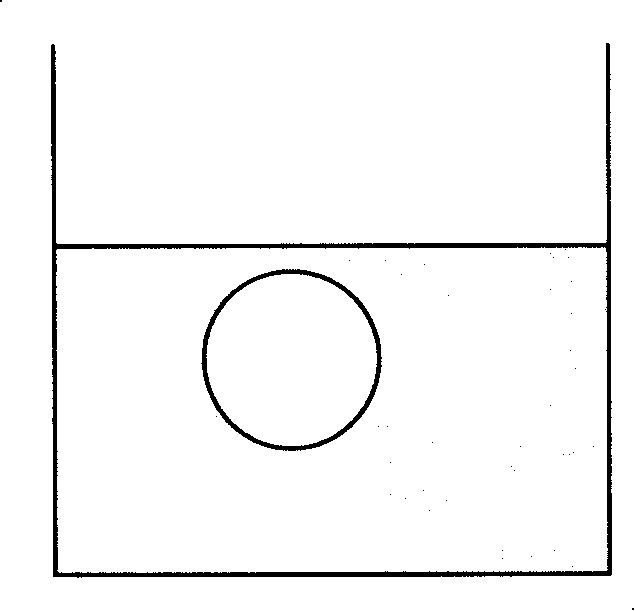

[0018] First, if figure 1 As shown, a number of silicon wafers are immersed in a wet chemical solution tank, the chemical solution tank is open, and the chemical solution contained therein is sulfuric acid (H 2 SO 4 ) and hydrogen peroxide (H 2 o 2 ) mixture; usually, the temperature of the liquid medicine is 150±10°C.

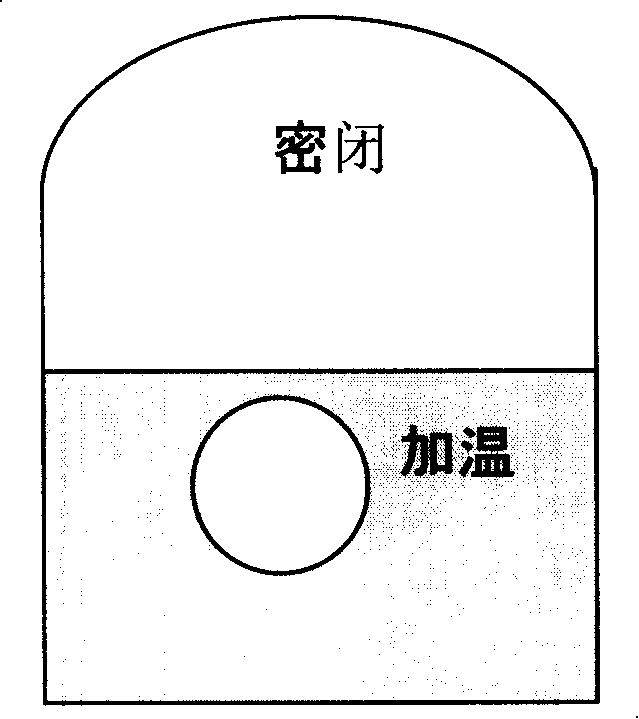

[0019] Then, if figure 2 As shown in Fig. 1, cover and seal the wet chemical solution tank, and heat the chemical solution at a temperature range of 180-240°C. When the temperature of the mixed chemical solution is 200±10°C, the degumming effect is the best. good.

[0020] After degumming, if the airtight tank is directly opened under high temperature environment, the depressurized hydrogen peroxide will volatilize rapidly, resulting in a rapid change in the ratio of sulfuric acid and hydrogen peroxide mixed solution.

[0021] Therefore, after the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com